1. Introduction | 2. Objectives | 3. Review | 4. Common Connectors | 5. Industrial Connectors | 6. Ingress Protection Rating | 7. Industrial Connectors Types | Related Components | Take the Quiz

Vote for the next Learning Module subject!

Also Available:

While consumer and industrial-grade connectors have essentially identical functions, industrial connectors are utilized in applications that diverge considerably from those used in consumer electronics equipment. What differentiates industrial connectors from PCB and common I/O connectors is the substantial amount of engineering that went into designing the integral environmental protection needed for proper connector operation in many harsh or hazardous industrial environments. If you are an electronics student, a hobbyist in the maker community, or if you have been a design engineer focused on consumer electronics products, this learning module will expand your knowledge of the most common types of industrial connectors used in a wide range of applications spanning, IoT, M2M communications, motor control, parameter monitoring, energy production, and more.

2. Objective

The objective of this learning module is to provide you with the essentials of industrial connectors. You will first review the purpose and functions of common types of home and commercial connectors in order to appreciate the differences between these connectors and industrial connectors. In the later sections, you will gain a thorough understanding of the types, features, and applications of industrial connectors.

Upon completion of this learning module, you will be able to:

Discuss the four types of home and commercial power connectors.

Discuss the four types of home and commercial power connectors.

Identify the difference between an IEC and a NEMA connector.

Identify the difference between an IEC and a NEMA connector.

Understand the main differences between a consumer and an industrial connector.

Understand the main differences between a consumer and an industrial connector.

Determine the level of ingress protection of an industrial connector based upon the EN/IEC 60529 IP rating system.

Determine the level of ingress protection of an industrial connector based upon the EN/IEC 60529 IP rating system.

Discuss the different types of industrial connectors and their applications.

Discuss the different types of industrial connectors and their applications.

3. ReviewBack to Top

Before discussing the types of industrial connectors, let's begin this learning module with a brief review of connector basics, starting with the definition of a connector. A connector was defined in the element14 Connectors Essentials One learning module in the following way:

'A connector is a device that is capable of connecting two circuit points, signals, or sub-systems with electrical integrity, mechanical durability, environmental protection and safety.'

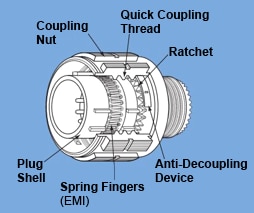

Electrical Integrity - connectors mate two points of a circuit with a very low contact resistance and provide protection from electromagnetic interference (EMI) and/or electrostatic discharge (ESD).

Electrical Integrity - connectors mate two points of a circuit with a very low contact resistance and provide protection from electromagnetic interference (EMI) and/or electrostatic discharge (ESD).

Mechanical Durability - a connector can withstand vibrations or environmental abuse without causing a failure in electrical integrity.

Mechanical Durability - a connector can withstand vibrations or environmental abuse without causing a failure in electrical integrity.

Environmental Protection - a connector's design meets the IP (Ingress Protection) ratings defined in the international standard EN/IEC 60529 for preventing the ingress of water, dust, debris, and other contaminants that would otherwise interfere with the electrical integrity of the connection.

Environmental Protection - a connector's design meets the IP (Ingress Protection) ratings defined in the international standard EN/IEC 60529 for preventing the ingress of water, dust, debris, and other contaminants that would otherwise interfere with the electrical integrity of the connection.

Safety - a connector is designed with features that eliminate personal hazards, or the risk of fire, shock or electrocution.

Safety - a connector is designed with features that eliminate personal hazards, or the risk of fire, shock or electrocution.

While this extended definition was originally written for a discussion on PCB-level, I/O peripheral and consumer product connectors, it also applies to the broad category of industrial connectors. But the key difference between consumer and industrial connectors is the degree by which each of these features is emphasized in the design of the connector.

To fully appreciate the engineering that went into the design of industrial conductors, it is worthwhile to digress a moment and discuss briefly some common types of home and commercial connectors. Understanding the differences between home/commercial and industrial connectors is a good way to become familiar with the unique characteristics of industrial connectors.

4. Common Types of Home and Commercial Connectors Back to Top

Power connectors are commonly used on extension cords and AC/DC adapters to power computers, home appliances and any number of devices we use in our daily lives. But a connector used to connect power to a typical kitchen appliance (e.g. toaster, coffee pot or blender) is quite different than one that would be used to power a 10 HP A.C. induction motor supplied by a 3-phase Wye (208/120V) power distribution system for an HVAC application. In general, power connectors used in homes or commercial buildings are grouped into the following types based upon their contact configurations:

Straight Blade: The straight-blade type is used to supply light-duty, general-purpose, electrical devices. The blades are flat, conductive and permanent contacts that mate with corresponding blade-sockets in the receptacle/inlet.

Locking: The locking type is used to supply moderate-to-heavy duty, commercial equipment that do not require a sealed connector. This type features a curved ground pin and an integral locking mechanism. An operator needs to insert-and-twist the connector/plug in the receptacle/inlet to supply power to the load and lock the plug into place. This locking feature provides increased protection against accidental disconnection. Connection security is an important feature because if a connector were removed from its receptacle while it was connected to a load, an arc flash event is likely to occur, resulting in a possibly deadly personnel safety hazard.

Pin-and-Sleeve: The pin-and-sleeve type is a heavy duty power connector that's constructed with a large contact pin that mates with a surrounding contact sleeve when connected. These connectors are employed where higher voltages and currents are utilized.

Poly-Phase: The poly-phase type is a heavy-duty commercial power connector that connects a 3-phase power distribution system to a 3-phase load such as a motor or a heater.

- 4.1 IEC Power Connectors

In order to ensure that a power connector will mate to equipment manufactured in different parts of the world, the design of connectors has been “harmonized” via manufacturing standards that are developed by organizations such as the International Electrotechnical Commission (http://www.iec.ch).

The International Electrotechnical Commission (IEC) is a non-profit, non-governmental, international standards organization that publishes standards for electrical, electronic and other technologies. The relevant IEC standard for the connectors discussed in this learning module is the IEC 60320: Appliance Couplers for Household and Similar General Purposes. The IEC 60320 sets the guidelines for two-pole appliance couplers with and without an earth ground pin for powering household and similar devices to a mains supply that does not exceed 250 VAC /16A. There are 13 pairs of IEC connector types. Here are a few examples:

- 4.2 NEMA Power Connectors

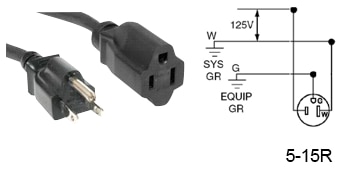

Another common home and commerical connector is the NEMA connector. The National Electrical Manufacturers Association (www.nema.org) is the U.S. association of electrical equipment and medical imaging manufacturers that develops NEMA standards for the manufacturing of home or commercial power connectors. NEMA connectors are primarily used in North America; however, they can be used in other countries. They have a broader range of voltage and current ratings than IEC connectors, 125 to 600 V and 15 to 60 A, respectively.

The relevant NEMA standard for the connectors discussed in this learning module is ANSI C119.6-2011: The American National Standard for Electric Connectors-Non-Sealed, Multiport Connector Systems Rated 600 V or Less for Aluminum and Copper Conductors. The standard covers non-sealed, multiport distribution connectors rated 600 V or less used to make electrical connections between aluminum-to-aluminum, aluminum-to-copper or copper-to-copper conductors for above-grade electric utility applications. There are 13 main categories of NEMA connectors (i.e., NEMA 1, 2, 5, 6, 7, 10, 11, 14, 15, 18, 21, 22, 23), covering both locking and non-locking types. Here are a few examples:

5. Introduction to Industrial Connectors Back to Top

The previous section was a short overview of common home and commercial connectors. Both IEC and NEMA connectors have a wide range of sizes in order to provide an effective connection solution for different power systems and voltage/current ranges. Moreover, they are employed in home and office applications around the world, which is a testament to their quality, reliability, and safety. But are they a good fit for the industrial environment? To answer the question, let's compare a NEMA and an industrial connector with similar ratings.

|

Non-Sealed Connectors

NEMA L16-30: 480V/30A, Non-Sealed (IP20) |

Splashproof Industrial Connectors

Amphenol |

Both of these connectors have similar ratings and would be used in similar applications such as connecting 3-phase loads to a 3-phase, 4-wire (L-L-L-G) power distribution system. But they are different in several respects, such as:

Connector Pin Exposure: The NEMA L16-30 has exposed contact pins while the Amphe-309 industrial connector's pins are shrouded by a casing to provide a greater amount of personnel hazard protection.

Connector Pin Exposure: The NEMA L16-30 has exposed contact pins while the Amphe-309 industrial connector's pins are shrouded by a casing to provide a greater amount of personnel hazard protection.

Color Coding: The Amphe-309 industrial connector's casing is color coded according to voltage and amperage ratings. In industrial situations where there are a lot of connectors mounted to a junction box (See image on left), the color coding of connectors is a decided advantage as far as operational readiness and maintenance convenience goes.

Color Coding: The Amphe-309 industrial connector's casing is color coded according to voltage and amperage ratings. In industrial situations where there are a lot of connectors mounted to a junction box (See image on left), the color coding of connectors is a decided advantage as far as operational readiness and maintenance convenience goes.

Ingress Protection: When the NEMA L16-30 plug is mated to its receptacle it provides a highly conductive and secure electrical connection. Despite these benefits, it has only an IP20 rating, which indicates it is non-sealed and therefore not recommended for use in wet/washdown industrial environments. Conversely, the Amphe-309 Series industrial connector has an IP44 rating, indicating that it is sealed to the point of making it splashproof.

Ingress Protection: When the NEMA L16-30 plug is mated to its receptacle it provides a highly conductive and secure electrical connection. Despite these benefits, it has only an IP20 rating, which indicates it is non-sealed and therefore not recommended for use in wet/washdown industrial environments. Conversely, the Amphe-309 Series industrial connector has an IP44 rating, indicating that it is sealed to the point of making it splashproof.

Keep these three differences in features in mind as we discuss the different types of industrial connectors in the subsequent sections of this learning module.

6. Ingress Protection Rating System Back to Top

In the last section, we touched on the topic of ingress protection. Let's take a closer look at this concept in this section. Environmental protection is a key feature of industrial connectors. As we learned in the last section, a non-sealed connector is not recommended for use in wet industrial environments. But how can we tell if a specific connector has the right level of environmental protection for a particular industrial environment?

This is done with an ingress protection (IP) rating system.

The EN/IEC 60529 standard has delineated an IP rating system that indicates the level of protection provided by an enclosure. While the standard explicitly defines these as IP codes for electrical enclosures, connector manufacturers also use this standard to identify the level of ingress protection for their products. The ingress protection rating system consists of “IP” plus a two digit code. The rating system is described in the following table:

| IP | First number - Protection against ingress of objects | Second number - Protection against liquids |

|---|---|---|

| 0 – No special protection | 0 – No protection | |

| 1 – Protected against solid objects over 50 mm, e.g. accidental touch by person's hands | 1 – Protection against vertically falling drops of water e.g. condensation | |

| 2 – Protected against solid objects over 12 mm, e.g. persons fingers | 2 – Protection against direct sprays of water up to 15° from the vertical | |

| 3 – Protected against solid objects over 2.5 mm (tools and wires) | 3 – Protected against direct sprays of water up to 60° from the vertical | |

| 4 – Protected against solid objects over 1 mm (tools, wires, and small wires) | 4 – Protection against water sprayed from all directions - limited ingress permitted | |

| 5 – Protected against dust limited ingress (no harmful deposit) | 5 – Protected against low pressure jets of water from all directions - limited ingress | |

| 6 – Totally dust tight | 6 – Protected against temporary flooding of water, e.g. for use on ship decks - limited ingress permitted | |

| N/A | 7 – Protected against the effect of immersion between 15 cm and 1 m | |

| N/A | 8 – Protects against long periods of immersion under pressure | |

| N/A | 9k – Protected against close-range high pressure, high temperature spray downs. |

Example: What does IP67 mean?

Answer: A connector that is totally dust tight (6 – first number) and water resistant (7- second number - protected against the effect of immersion between 15 cm to 1m).

7. Types of Industrial ConnectorsBack to Top

Industrial power connectors are designed to safely and reliably provide power to equipment in harsh, high temperature, and other extreme environments such as wastewater treatment plants, oil production facilities (offshore rigs), mining operations, food/pharmaceutical processing plants and others. In general, industrial connectors are grouped in the following categories:

- 7.1 Harsh Environments

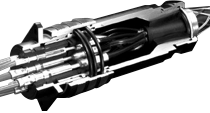

- 7.2 High Vibration Connectors

- 7.3 Explosion Proof Connectors

Some industrial environments are explosion hazards due to the presence of flammable gases, dusts, mists or vapors in their atmospheres. Petrochemical refineries, land and offshore drilling systems are environments that can have flammable atmospheres. But flour & feed mills, grain silos & elevators, and coal & coke plants are dust explosion hazards. To mitigate the risks associated with these hazardous environments, explosion proof connectors have been designed to ensure that the device itself does not ignite an explosive chain reaction. In the context of industrial environments, explosion-proof connectors are manufactured with greater precision so that the arcing or sparks that occur inside the device do not ignite flammable gases, vapors or mists as well as combustible dusts that are present in the surrounding atmosphere. Some industrial environments are explosion hazards due to the presence of flammable gases, dusts, mists or vapors in their atmospheres. Petrochemical refineries, land and offshore drilling systems are environments that can have flammable atmospheres. But flour & feed mills, grain silos & elevators, and coal & coke plants are dust explosion hazards. To mitigate the risks associated with these hazardous environments, explosion proof connectors have been designed to ensure that the device itself does not ignite an explosive chain reaction. In the context of industrial environments, explosion-proof connectors are manufactured with greater precision so that the arcing or sparks that occur inside the device do not ignite flammable gases, vapors or mists as well as combustible dusts that are present in the surrounding atmosphere. |

|

Amphenol |

- 7.4 Multipin Connectors

- 7.5 Vehicular Connectors

- 7.6 Solar Connectors

Solar energy is one of the most common types of renewable energy today. Consider this: Nearly 784,000 U.S. homes and businesses have solar systems. There are now over 22,700 MW of cumulative solar electric capacity operating in the U.S., enough to power more than 4.6 million average American homes, according to the Solar Energy Industries Association Solar energy is one of the most common types of renewable energy today. Consider this: Nearly 784,000 U.S. homes and businesses have solar systems. There are now over 22,700 MW of cumulative solar electric capacity operating in the U.S., enough to power more than 4.6 million average American homes, according to the Solar Energy Industries Association |

|

The Amphenol |

*Trademark. Amphenol Industrial is a trademark of Amphenol Corporation. Other logos, product and/or company names may be trademarks of their respective owners.

|

Test Your KnowledgeBack to Top

Are you ready to demonstrate your Connectors knowledge? Then take a quick 15-question multiple choice quiz to see how much you've learned from this Essentials Connectors 2 module.

You'll see your score at the end of the quiz. If you score 100%, you're on your way to earning your Connectors Skills 2 badge, and 125 points. To fulfill all the requirements for earning this skills badge, you will also need to post a feedback comment on this Essentials Connectors 2 page to let us know what you thoughts on the module, and vote in our poll to help decide what our next Essentials learning module topic should be.