Hello friends !

Today i would like to share my own X-Ray machine that was made from old MX-20 X-Ray parts. No information was present about controller, so I have to figure-out everything my own

Everything was made by me, box, electronics, only sensor and x-ray source (well, and tablet obviously) was outsourced from eBay  (lucky find) Box was designed in SolidWorks and made from MDF board covered with oak.

(lucky find) Box was designed in SolidWorks and made from MDF board covered with oak.

All internal surfaces was covered by 2mm powder coated aluminum sheets as well as 0.5mm lead shielding. In reality due to physics how x-ray are produced,only scattering will go sideways, 2mm+ 0.5mm for shielding for 35kev energy is just too much. No radiation was detected outside the box, great news ! Also X-ray generator was using only 20W of power, and this is special kind of tube, where is no filament, I don't exactly know how it works. What is good that is 50um spot size. This is perfect match for Hamamatsu C9732DK-11 Sensor :

The C9732DK-11 is two-dimensional CMOS image sensor module designed for X-ray imaging which requires high resolution, large area and wide dynamic range. A target material of X-ray source and X-ray energy adequate for the sensor is Mo and 17 keV. The device shape is thin casette which incorporates on-chip high-resolution scintillator and a control board. An on-board USB 2.0 interface can realize fast data transfer to the C9732DK-11.

Features

- 2400 × 2400 pixels

- High resolution

- 14-bit digital output (USB 2.0 interface)

- High-speed imaging: 1 frames/s

- No dead area (insensitive area) due to seamless structure

- Compatible with HAMAMATSU API (DCAM-API, and whis is what i use in my own program)

This that first project that used FPGA. I want to learn how to create custom electronics with it, and hardware for me is not a problem. I made boards with 800pin FPGA's for other to program  All programming is done via schematic implementation, so no need to write code, just place parts from libraries to form SPI shift register or do some basic math to scale register value to nonlinear voltage that x-ray generator is using for energy set-point. Power supply is generated from 24V, i need 5V 5A for Hamamatsu sensor, isolated +12,-12,+5V for X-ray generator, and another 12V for controller board as well as stepper drivers.

All programming is done via schematic implementation, so no need to write code, just place parts from libraries to form SPI shift register or do some basic math to scale register value to nonlinear voltage that x-ray generator is using for energy set-point. Power supply is generated from 24V, i need 5V 5A for Hamamatsu sensor, isolated +12,-12,+5V for X-ray generator, and another 12V for controller board as well as stepper drivers.

And here is how it looks all inside machine

Programming is done on Intel 10M08SAE144C8G FPGA

This is how part of program looks like  Not very exiting, and not very complex, just data registers, shift registers, MAC, comparators, triggers, gates, tri-bus drivers and so on

Not very exiting, and not very complex, just data registers, shift registers, MAC, comparators, triggers, gates, tri-bus drivers and so on

(complete project can be downloaded below).

What still need's to be developed is stepper motors, so i can twist sample in axis, that could let me to create 3D structure based on backprojection algorithm

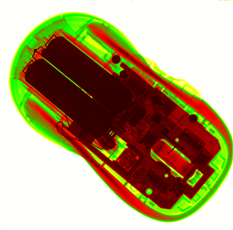

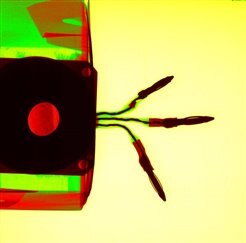

Lets take a different view (  ) on common objects. They look so fascinating than you can see inside, and start to understand how much we get forward in technology.

) on common objects. They look so fascinating than you can see inside, and start to understand how much we get forward in technology.

If you can recognize some parts, please leave comment below what is what

Here quick video how to do video of spinning rose

Also you can find information in HackADay.io page of this project:

Top Comments