Table of contents

Abstract

We have already build a PCB cutting machine for at least 1.5 years back for cutting PCB. The problem with it is it used to get over heated and I wasn't aware about it that it got over heated. Having no intimation about its heating may lead to failure of the DC motor that was used for cutting PCB(Printed circuit boad)

Project

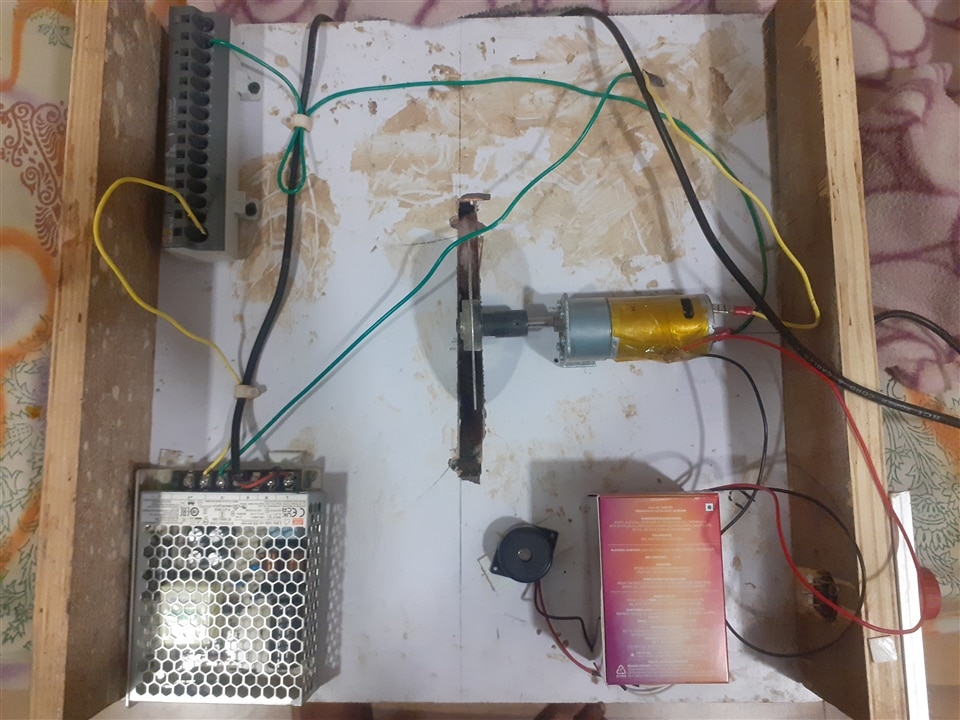

I have already build a PCB cutter for at lest 1.5 years back for cutting PCB. More often or no the DC motor used to get hot after 1 hour of use. I was looking for way to protect the DC motor that I am using in the PCB cutter. I decided to build and implement safety system for the PCB cutter. Temperature measurement and indication of motor over heating is also one of the requirement I need to satisfy. For a motor to be safe to use it's temperature should not go beyond 50'c. If it goes you should get an indication about it. bellow is the image that display how we have attached RTD temperature sensor to the DC motor.

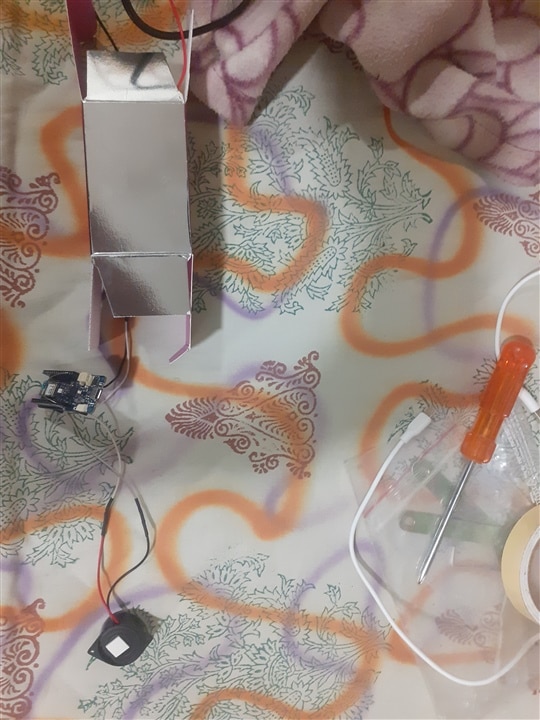

The RTD is glued to the motor using Kapton tape. So that the RTD can measure the motor temperature and send that information to the mkr Wifi 1010 development board. The mkr Wifi 1010 board checks for temperature weather it is above 45'c and bellow 50'c give a 5 beep indication and if the temperaure is above 50'c it gives 1 long beep indication. bellow is the image of how we have fitted the mkr Wfi 1010 to the paper box.

After fitting the mkr wifi 1010 board in the box. We have assembled the entire system in the PCB cutter. which is shown bellow.

Bellow is the video that is showing buzzer response when the dc motor gets over heated.