Mask straps removed and magnetic snaps added. Exhaust valve also removed.

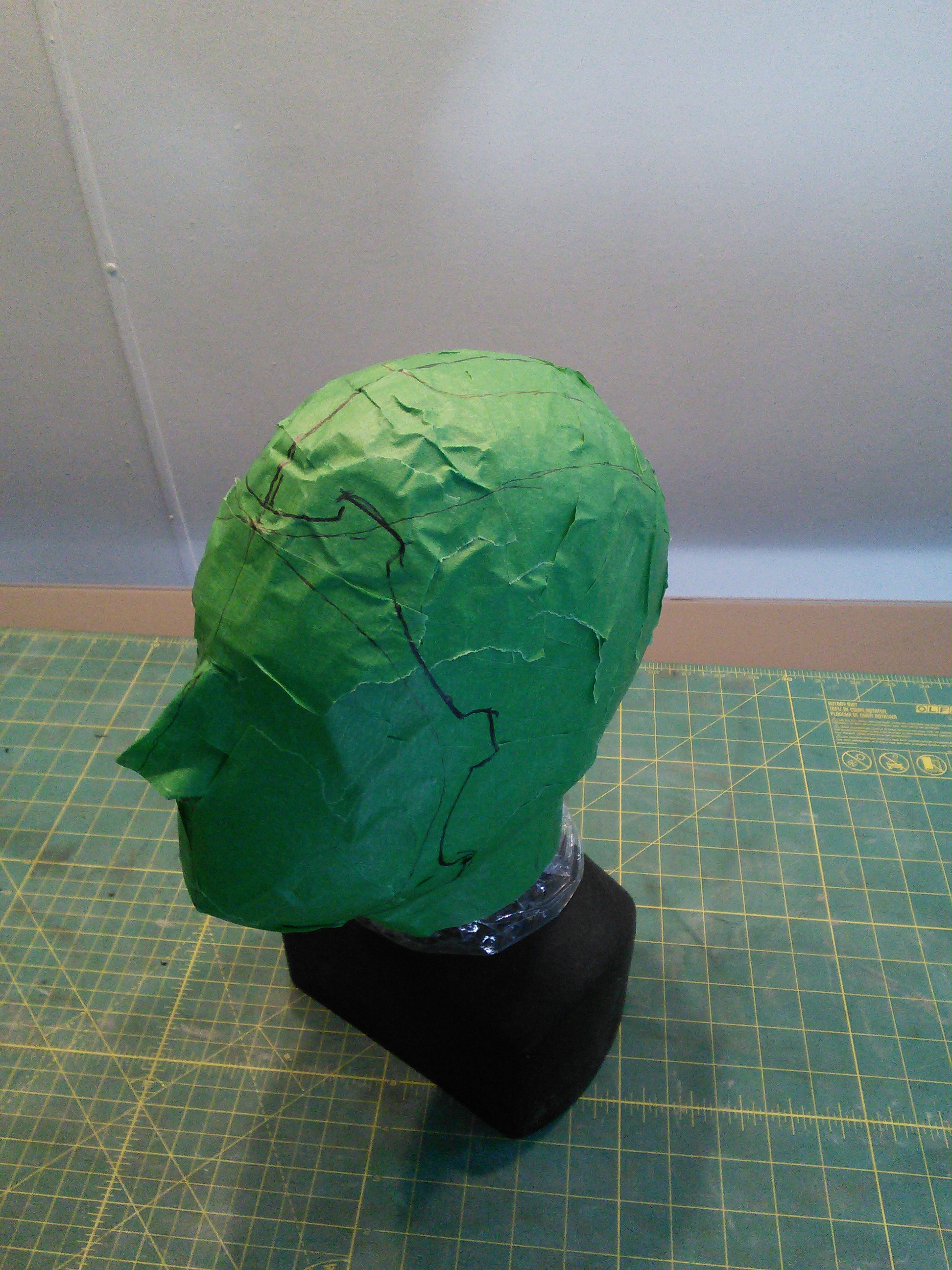

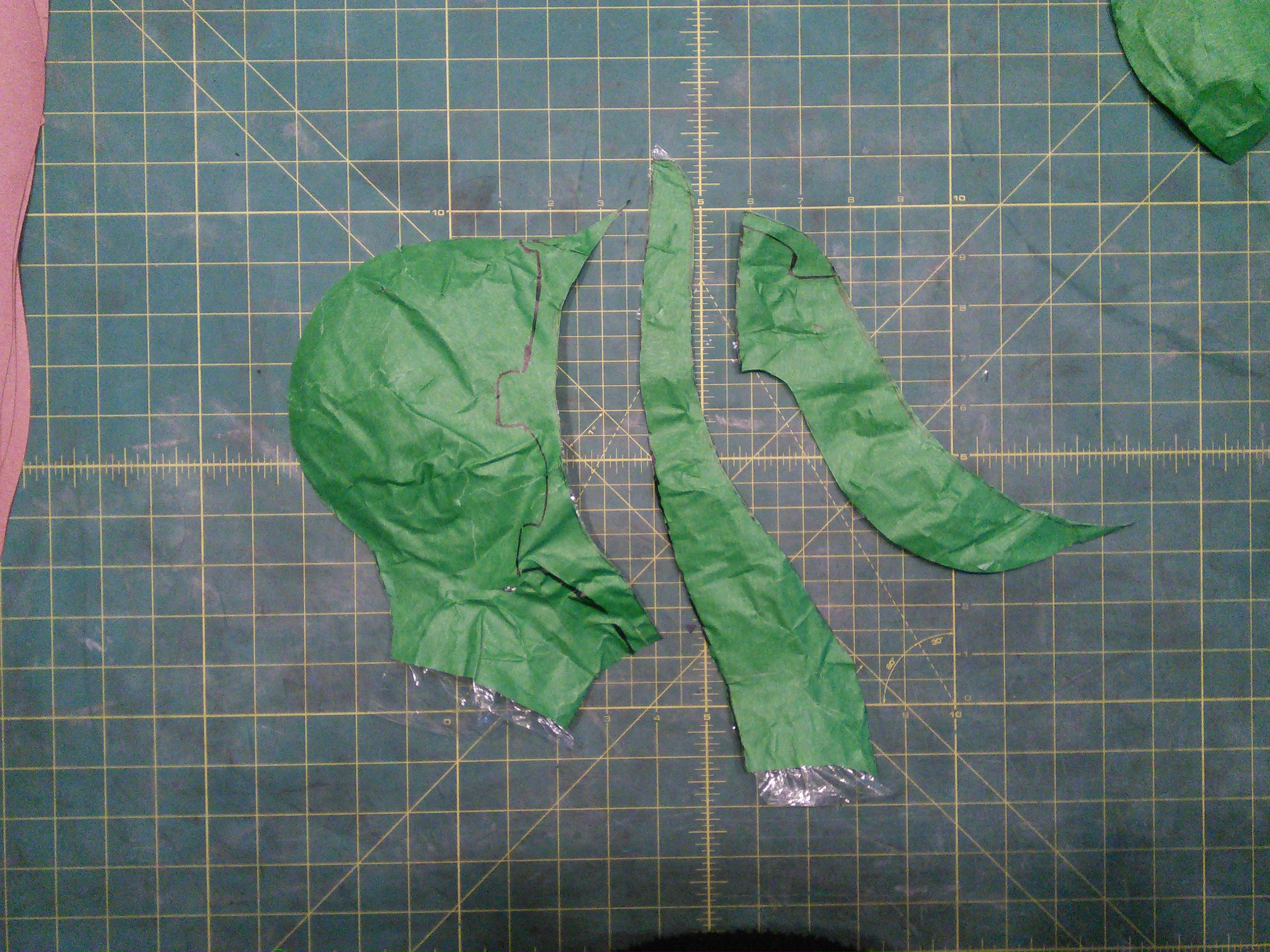

Next was to make the hood replacing the straps. This was done by having a friend cover my head in plastic wrap and masking tape. Paper tape was used because it does not stretch when applied. The cast was cut off then marked and cut to create pattern pieces. Tape parts are then placed on the cutting matt and photographed to use for creating digital pattern parts. After acceptable pattern is drawn; it was laser cut in paper and tested for shape. after paper parts were accepted seam allowances and reference markers are added to the pattern. Finally cut and glued in latex.

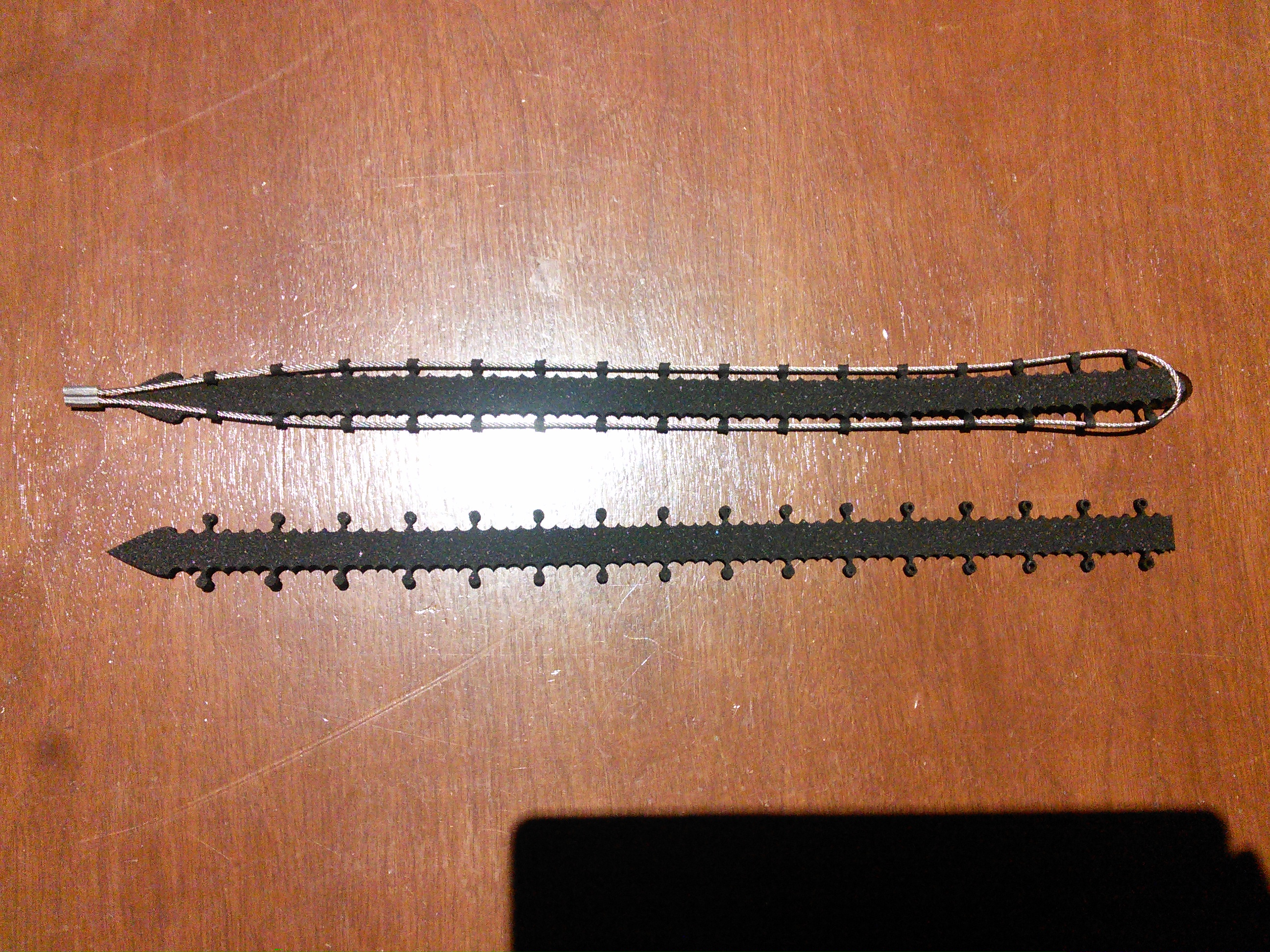

I decided to add some cyber falls. The catch with a latex hood is that all the parts no stretch parts must be removable. The soltion I came up with was to use small D-rings and magnets. The dees are attached to the hood and magnets in the base of each fall. The falls were laser cut out of EVA foam; then trimmed with stainless steel aircraft cable. outriggers holding the cable are given a 1/4 turn to be laser cut and still hold the trim.

The rest tomorrow. The wiring, code, bits and bobs.

Top Comments