Mechatronics is the integration of electronic, mechanical, and control engineering to design simpler and more reliable products. Tetsuro Mori, a senior engineer at the Japanese company Yasakawa, coined the term in 1969. Since then, developments in semiconductor integrated circuits (ICs), sensor/actuator technologies, signal processing, embedded computer & logic systems, and software & data acquisition have expanded the scope of mechatronics to include simple products, such as home appliances, laser printers, and other consumer electronic products, as well as complex products like CNC machines, mobile robots, anti-lock braking systems, industrial 3D printers, and Internet of Things systems and products. This learning module is an introduction to mechatronics, including its processes, systems, components, and applications.

2. Objectives

The objective of this learning module is to help you understand how the influence of mechatronics as a design approach now impacts an engineer’s work, whether it is designing manufacturing processes, home automation, or commercial end-products.

Upon completion of this module, you will be able to:

Explain the importance of interdisciplinary evaluation and integration of electronic, mechanical, and control engineering

Explain the importance of interdisciplinary evaluation and integration of electronic, mechanical, and control engineering

Describe the essentials of mechatronics from a systems analysis point of view

Describe the essentials of mechatronics from a systems analysis point of view

Understand the importance of semiconductor switches utilized in mechatronic designs

Understand the importance of semiconductor switches utilized in mechatronic designs

Discuss how a mechatronics system is utilized in a manufacturing process and home automation

Discuss how a mechatronics system is utilized in a manufacturing process and home automation

Mechatronics is the synergistic integration of mechanical, electronic, electrical, and computer engineering used in the design of products and automation systems. It also implements components such as logic, feedback, and data processing to simulate human thought processes that are realized in automation. Mechatronics has had an evolutionary development over the past 50 years, propelled by advances in electronics, enabling the creation of different types of intelligent products. Engineers and scientists from multiple fields of engineering have contributed to mechatronics, with technologies such as measurement systems, sensors, adjustable frequency drives, actuation systems (e.g., electric motors, air/hydraulic pumps), microcontrollers, microprocessors, analog and digital electronics, power electronics, machine learning, Internet of Things (IoT), information technology, software engineering, and more. Figure 1 illustrates the integration of these technologies to realize the mechatronics design approach used today.

Mechatronics impacts not only the design of end-products that consumers purchase, but also the production equipment and processes used to manufacture end-products. In this section, we’ll discuss some of the main benefits of mechatronics.

Parts Reduction: Mechatronics systems reduce hardware complexity by integrating multiple devices into a single package. For example, MEMS and NEMS-based devices, CMOS signal conditioning circuits, and intelligent controllers are constructed on a single silicon chip, which reduces the complexity and size of the system.

Parts Reduction: Mechatronics systems reduce hardware complexity by integrating multiple devices into a single package. For example, MEMS and NEMS-based devices, CMOS signal conditioning circuits, and intelligent controllers are constructed on a single silicon chip, which reduces the complexity and size of the system.

Modular Integration: Mechatronics systems utilize re-configurable modular components that allow plug-and-play operation, enabling interoperability, and allowing for quick installation, repair, and swap-outs. The benefit of modular integration also extends to distributed power, motion control, intelligence, and I/O.

Modular Integration: Mechatronics systems utilize re-configurable modular components that allow plug-and-play operation, enabling interoperability, and allowing for quick installation, repair, and swap-outs. The benefit of modular integration also extends to distributed power, motion control, intelligence, and I/O.

Low Power Consumption: Electromechanical relay switches consume more power to generate electromagnetic fields to perform the switching action. In mechatronic systems, electrical and mechanical switches are replaced with electronic switches, such as MOSFETs, IGBTs, SCRs, and TRIACs, that consume less power and are more reliable. In addition, a system constructed with MEMS (micro-electro-mechanical systems) / NEMS (nano-electro-mechanical systems) actuators and sensors consumes much less power than conventional electromechanical components.

Low Power Consumption: Electromechanical relay switches consume more power to generate electromagnetic fields to perform the switching action. In mechatronic systems, electrical and mechanical switches are replaced with electronic switches, such as MOSFETs, IGBTs, SCRs, and TRIACs, that consume less power and are more reliable. In addition, a system constructed with MEMS (micro-electro-mechanical systems) / NEMS (nano-electro-mechanical systems) actuators and sensors consumes much less power than conventional electromechanical components.

Flexibility: Mechatronic systems can be reprogrammed to change product features without a change of hardware. Some mechatronic systems automatically modify the machinery parts according to controller instructions and perform different tasks at different stages of the manufacturing process.

Flexibility: Mechatronic systems can be reprogrammed to change product features without a change of hardware. Some mechatronic systems automatically modify the machinery parts according to controller instructions and perform different tasks at different stages of the manufacturing process.

Easier Problem Diagnosis: Since mechatronic systems' components are highly integrated, there are fewer overall parts and fewer wired interconnections between components, which results in reduced time spent in problem diagnosis when faults do occur. In IoT-enabled mechatronics systems, operators use an application software or browser on a computer or smartphone to obtain visualizations into remote systems from any remote location. They can monitor system status through automatically generated text message notifications and voice commands. Predictive maintenance algorithms help to identify system degradation problems and take corrective action before a shutdown occurs.

Easier Problem Diagnosis: Since mechatronic systems' components are highly integrated, there are fewer overall parts and fewer wired interconnections between components, which results in reduced time spent in problem diagnosis when faults do occur. In IoT-enabled mechatronics systems, operators use an application software or browser on a computer or smartphone to obtain visualizations into remote systems from any remote location. They can monitor system status through automatically generated text message notifications and voice commands. Predictive maintenance algorithms help to identify system degradation problems and take corrective action before a shutdown occurs.

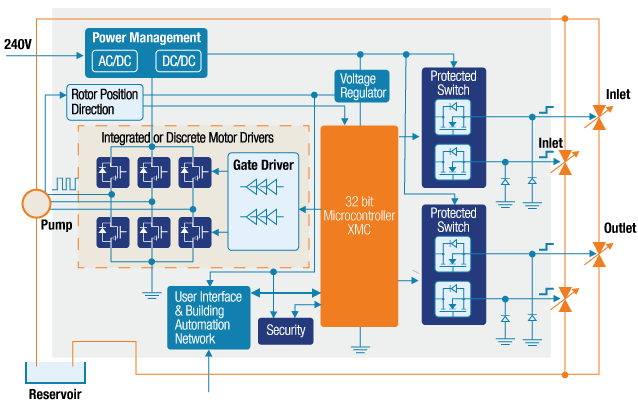

In this section, let's describe a comprehensive mechatronics system in order to gain a thorough understanding of its sub-components and operation. A block diagram of this mechatronics system is shown in Figure 2.

Power Control Unit: The power control unit provides the required power for each component in the system. It consists of isolation transformers, fuses, AC-DC rectifiers, DC-DC converters, and battery protected switches. Mechatronics systems usually have distributed or de-centralized power architectures. The power control unit also houses power protection circuits that protect the system from power anomalies in the primary power supply such as surges, spikes, sags, overvoltages, line noise (RFI/EMI), etc.

Human-Machine Interface (HMI): The human-machine interface (HMI) or human-computer interface (HCI) informs the operator of system status, inputs and outputs, alarms, etc. It is some type of textual or display interface that can also allow an operator to assign the tasks, time, and priority of the process.

Control Unit: The control unit consists of a closed-loop controller with feedback circuit that precisely tracks reference variables and maintains an approximately linear behavior in the system. A mechatronic system can possess one or many controllers. They take user and sensor inputs and run the algorithm designed to provide a control signal to operate the actuators. A variety of controllers built around digital ICs (e.g., logic gates), microprocessors, microcontrollers, and analog circuits are typically used. Microcontroller- and microprocessor-based controllers allow flexible configuration of the control process. Logic gates, embodied in field programmable logic arrays, offer a digital control approach with the benefits of flexibility, performance, parallelism, reusability, and reconfigurability.

Programmable logic controllers (PLCs) are microprocessor-based control units specially designed for industrial applications. They consist of a memory storage space, CPU, and an I/O interface. The PLC Input ports accept analog or digital signals. The inputs flow through ladder diagrams, sequential function charts, functional block diagrams, or structured programs (PLC programming language) to produce outputs that may be analog, PWM, or logic. PLCs support various industrial protocols such as MODBUS, EtherCAT, PROFINET, CANopen, and Ethernet, making them a good option for complex mechatronics systems.

Application software essentially provides the intelligence of the mechatronics system. The software structure and flow of control statements are responsible for the proper handling of high priority tasks, solving complex mathematical equations, and controlling hardware connectivity. A variety of software development tools are available to generate software code, such as MATLAB, LabVIEW, Arduino, Pycharm, Keil, and LogiCircuit.

Digital Communications: The demand for flexibility in process control has led to connecting mechatronic systems to the Internet. Simple communication between small network devices can be done by a local area network (LAN). Standard protocols like ISO/OSI or TCP/IP can be used to implement data communication over the network. Depending on the number of devices connected, the mode of communication can be point-to-point (RS-232 from PC COM port), point-to-multipoint (CANOpen, MODBUS, EtherCAT, and PROFINET), or broadcast communication. These communication modules help to share process information, such as the relative position of actuators and the measured values of sensors.

Actuators: Actuators are state-devices used to amplify the controller output. Switches are the main functional part of the actuator driver. Apart from the switching devices, the driver also has control ICs, safety protection circuits, and onboard sensors. Depending on the design and mechanical moving parts, switches can be classified into two ways: electromechanical switches and solid-state switches.

Electromechanical Switches: These provide either an ON or OFF state, based on a change in input excitation such as current, magnetic field, temperature, etc. The outputs of the switch, which may be in a contact or non-contact state, allow changing the flow of the electric current to another circuit. Relays are examples of electromechanical switches used to isolate low power circuits (controllers) from high power circuits.

Electromechanical Switches: These provide either an ON or OFF state, based on a change in input excitation such as current, magnetic field, temperature, etc. The outputs of the switch, which may be in a contact or non-contact state, allow changing the flow of the electric current to another circuit. Relays are examples of electromechanical switches used to isolate low power circuits (controllers) from high power circuits.

Some types of electromechanical relays include:

Solid-state Switches: Solid-state switches are electronic switches which do not have mechanical moving parts, and can be controlled by a digital signal. Electric motors, inverters, and temperature control applications use electronic switches such as diodes, bipolar transistors, thyristors, MOSFETs, and IGBTs in their power circuits.

Solid-state Switches: Solid-state switches are electronic switches which do not have mechanical moving parts, and can be controlled by a digital signal. Electric motors, inverters, and temperature control applications use electronic switches such as diodes, bipolar transistors, thyristors, MOSFETs, and IGBTs in their power circuits.

An electric motor drive can include IGBTs or MOSFETs, gate driver ICs, and protection circuits. These circuits provide the latch-up effect, even in cases of high dv/dt switching under elevated temperature. Some of these control ICs have integrated thermistors for over-temperature protection. Actuator driver modules improve system performance and energy efficiency by delivering increased power density, enhanced system ruggedness, and reliability. These drivers consist of semiconductor switches connected in different combinations, like a high-side switch, low-side switch, half bridge, full bridge driver, and inverter circuits.

Mechanical Utility: Actuators convert electrical energy into mechanical energy typically in the form of motion. Prior to the advent of mechatronics systems, diesel engines, hydraulic tubes, solenoids, and electro-cylinders were used to produce mechanical force. But today, stepper motors, brushed DC motors, brushless DC motors, induction motors, and synchronous motors are used in mechatronic systems to produce mechanical torque for angular rotation. Energy efficient brushless DC (BLDC) motors are used to achieve high precision positioning. For example, typical automotive applications like door mirrors, power windows, power seats, and electronic throttle valves use brushless DC (BLDC) motors in their operation.

Sensors: Sensors are used to measure environmental parameters and system outputs. They generate an analog or digital signal to estimate an attribute of environmental factors such as temperature, pressure, stress, strain, or system outputs such as motor speed, the presence of objects, object distance, and liquid level. Some typical sensors used in mechatronic systems are temperature sensors, IR sensors, light sensors, ultrasonic sensors, touch sensors, linear variable displacement transformers (LVDTs), rotary potentiometers, proximity sensors, pressure sensors, level sensors, and smoke, alcohol, or gas sensors.

Feedback Circuits: A feedback circuit includes transducers such as voltage dividers, amplifiers, and frequency to voltage converters. It generates a digital or analog signal which is acceptable from the controller. Some controllers have an on-chip ADC controller that helps to convert the analog signal (sensor outputs) to digital signals within the controller.

Mechatronic systems help to improve the performance of a range of applications, from white goods and automotive to industrial process control, robotics, and more. In this section, we will discuss some of these applications.

- 6.1 Automotive

Due to the increased demand for new features in electric vehicles (EVs), mechanical-based automotive applications have been replaced with mechatronic systems. For example, the engine control unit, mirror controllers, and HVAC systems include a variety of mechatronic systems such as electrical motors, drives, inverters, sensors, and controllers. Within an electric vehicle’s drivetrain, an inverter controls the EV drive motor. A controller provides the switching signals for the inverter to drive the EV motor (synchronous, asynchronous, or brushless DC motor). It can also capture kinetic energy via regenerative braking.

Regenerative braking enables an EV's motor as a generator in order to convert the kinetic energy that would be dissipated via friction brakes during braking into potential energy that's restored or returned to the EV’s battery. This energy can be used again for the EV's acceleration at a future date.

System Basis Chips offer high integration and performance in small or accessory applications such as body control modules, gateways, closure modules (e.g., door, roof, tailgater, trailer, etc.), seat control modules, gear shifters, and fuel pumps.

In conventional braking systems, there is the chance of the wheels locking up, causing in some situations the dangerous condition of vehicle skidding. To prevent the wheel lock up condition, antilock braking systems (ABSs) have been designed to prevent the wheels from locking up. Sensors connected to each wheel report the rotational speed of the wheels and the brake pedal position to the controller. The algorithms in the controller analyze the data and take necessary action to change the speed of the braking actuator (linear motor, pump, solenoid, piston, etc.).

Millimeter wave radar technology has been developed as a safety measure for automotive applications. This system uses a wave radar to detect the location of objects surrounding the vehicle and calculate the distance to the objects, and the velocity in real-time. This system helps to activate the braking systems to prevent an accident.

In a hybrid electric vehicle (EV), alternators can be used to regenerate electric energy from wheel inertia. A simple, functional block diagram of a mechatronic alternator circuit is shown in Figure 3.

The alternator-regulators provide an energy supply for the vehicle. Their high efficiency contributes to a noticeable reduction in fuel consumption. AC generators produce alternating current (AC) using input momentum from the motor and rectifiers then convert AC Power to DC power and enable charging of the vehicle's batteries.

- 6.2 White Goods

White goods are home appliances such as refrigerators, washing machines, microwave ovens, mixer-grinders, ceiling fans, and air-conditioners. Mechatronic technology enables the design and manufacture of highly efficient systems with the right feature set, such as stable and smooth starting, a wide range of programs and cycles, and vibration suppression. Intelligent Power Modules (IPMs) are typically incorporated into these systems. IPMs are highly integrated, compact power modules designed to drive motors used in home appliances.

Washing machines are a good example application of mechatronics. They consist of electric motors, motor drivers, valves, buzzers, leak detectors, a spin out-of-balance detector, power mains failure sensors, and a controller. Figure 4 shows a functional block diagram of a mechatronic-based washing machine.

The sensors produce signals which are captured as digital inputs by the controller and are used to generate a control signal. PWM signals change the direction of the motor, as well as the motor speed depending on the load. In this system, switches and the controller take into account the temperature and vibration of the system to help to reduce pulsations and noises produced in spin-drying.

Another developing trend in home appliances is remote connectivity in a smart home environment, using communication protocols such as WiFi, Bluetooth, ZigBee, Z-wave, and MQTT. The Application Program Interfaces (APIs) program on a smartphone or PC then allows the user to control the system remotely.

- 6.3 Heating, Ventilation, and Air Conditioning (HVAC)

HVAC is used in home/commercial buildings and automotive vehicles to maintain constant temperature and air flow. These systems maintain room temperature either by heating or cooling. In the cooling process, the refrigerant in the chiller decreases the water temperature, and the chilled water then goes to cooling coils to produce cold air. A motor-driven pump is used to circulate chilled air through the pipes. In the heating process, a boiler generates hot water or steam that is piped to heating coils. Products used in HVAC applications need to have adequate thermal margin and be able to dissipate the excess heat. Analog interface functions are used to achieve sensor-less field oriented control (FOC) of the motor; this is also known as a vector control method. FOC provides better efficiency at higher speeds than sinusoidal control. The basic requirements for operating an HVAC system are related to the integrated components, such as IGBTs and gate drive ICs. A typical HVAC system diagram is shown in Figure 5.

The power management block consists of battery protection switches, as well as AC-to-DC and DC-to-DC converters to supply the required energy for all functional blocks. A PMSM motor is used to pump the hot or cold air through the pipes.

The microcontroller has application software to control the overall system functions. The controller acquires information signals from the user interface unit, a rotor position detector, security modules, and environmental sensors to produce the control signals. The microcontroller produces a 3-phase inverter PWM signal to control the HVAC Pump. The integrated gate drive circuit and three-phase inverter take the microcontroller output to produce a three-phase alternating current. Inlet and outlet valves are used to direct the flow of air either inside or outside of the building. These are electromechanical valves controlled by MOSFET or IGBT switches.

- 6.4 Autofocus Camera

Camera manufacturers aim to provide the best-focused lens position in their products. Demand for auto exposure (AE), auto white balance (AWB), and autofocus (AF) are trending in the digital camera market. An autofocus method can speed up search time and increase focusing accuracy. This feature can automatically choose what to focus on, and how to balance light levels to snap a good photo. A dedicated sensor and small actuator are designed to detect and adjust the position of the camera lens.

Autofocus cameras use MEMS technology-based actuators, which are used to adjust the lens position. Sensors detect light levels and angles, and the microprocessor determines distances and objects to focus on, including automatically detecting faces to focus on in a photo. Figure 6 shows a block diagram of an autofocus camera.

In this system, the mechanical arrangement between actuators and lens is used to adjust the lens focus and apertures. The microprocessor controls the actuator's speed and direction using the feedback signal. The measured image focus value is periodically fed back to the microprocessor to calibrate the quality of the image. The feedback period or match refresh rate should be fast, because the microprocessor can perform this action quickly and can adjust the lens position in a real-time environment.

- 6.5 Robotic Vacuum Cleaner

The idea behind a robotic vacuum cleaner is to clean floors and stairs by making independent decisions. A completely automated vacuum cleaner can detect room sizes. A robotic vacuum cleaner consists of a microcontroller, vacuum pump, high speed and low-speed motors, motor driver, and ultrasonic (obstacle avoidance) sensors.

Usually, robots have an in-built battery source and highly efficient power management unit. The controller captures the sensor signal and produces the control signals to drive the motors. High-side or low-side switches can be used to control the vacuum pump. An H-bridge converter is used to control the high-speed DC motor which is connected to sweeper brushes. The slow-moving stepper motors connected to wheels help to move the robot from one position to another position. Bluetooth connectivity allows remote control via mobile app or smartphone. An LCD provides a local readout for operational indicators, time settings, and other programming functions.

- 6.6 Computer Numerical Control

A computer numerical control (CNC) machine is a good example of a mechatronics system in a manufacturing application. Computer Aided Manufacturing (CAM) or Computer Integrated Manufacturing (CIM) systems are an integral part of the CNC machine. The CNC machine operates tools by sending a series of coded instructions which the machine control unit (MCU) can understand. The MCU consists of a CPU (central processing unit), memory, and I/O interface. It reads the program from the stored media (memory of the CNC computer) and executes the instructions to derive electrical signals that control the process of carrying out guaranteed operations on a workpiece. The controller and actuators automatically control the axial movements of machine tools. The CNC machine provides sequential control for other machine tool functions. Manual operation of work table and spindle actions are automated by using controllers and servo motors. It also has self-diagnostics facilities which frequently alert the operator in case of any safety issues.

*Trademark. Infineon is a trademark of Infineon Technologies. Other logos, product and/or company names may be trademarks of their respective owners.

Shop our wide range of development boards, microcontrollers, motor control ICs, intelligent power modules (IPMs), system basis chips, thyristor modules, bridge rectifiers, solid state relays, and more.

Back to TopTest Your Knowledge

Are you ready to demonstrate your Mechatronics knowledge? Then take a quick 15-question multiple choice quiz to see how much you've learned from this learning module.

To earn the Mechatronics Badge, read through the module to learn all about Mechatronics, attain 100% in the quiz at the bottom, leave us some feedback in the comments section, and give the module a star rating.

Top Comments