Follow along as I poke and prod at a traffic signal!

I may know someone who has an old US traffic light that needed a replacement Yellow and was surprised to find them readily available on eBay for only $10 (plus shipping). Of course I had to open it up and have a peek inside and was quite surprised at what I found.

The original was marked as "DR6-YTFB-20A-40-FL". The Red signal used RTFB and the green was GTFB (Green Traffic Beacon I'm assuming). This is made by General Electric.

I was kind of expecting either old school incandescent spot/flood light running at mains voltage; or a simple bank of LEDs. After opening it up and going through the circuit, there was quite a bit going on.

What's inside?

The first thing I noticed was that there were way components on the board than I would have expected. Two discrete IC chips, three switching transistors, and two MOSFETs; along with two large(ish) transformers and loads of other passives like resistors and capacitors. Oh - and LEDs - about 137 of them! I could quickly identify the AC to DC section with four diodes and some caps; along with a fuse and a common-mode choke. But past that, this was a spaghetti mess of components floating in a sea of LEDs.

I was really curious how there could be so much going on for what I would have considered as a simple 'dumb' light that is either ON or OFF, so I went a step deeper and reverse engineering the device.

To start, I took a front and back picture and pulled it into Gimp (open source equivalent of Photoshop). The two images were overlaid on different layers so that I could turn them on or off and view what was underneath. To do this, one of the images needed to be flipped horizontally so that the components line up properly. Being able to easily turn layers on and off made it so much easier to see which through-hole component lined up with each solder joint on the back. Then I created another couple of layers to physically trace the circuit using colored lines. I was able to use European colors of Blue/Brown for mains voltage in, then Red/Black for power+gnd (DC). And a few other colors for the other traces between components.

I've never traced out a board like this, so was kind of flying blind on what was the best method. I started by tracing the mains circuit in since that was easiest; and was able to isolate the DC bus that comes off of it. Then I moved over to each of the 8-pin DIP ICs and traced everything that connected to them. One of the last pieces was the transistors and MOSFETs. I kept one layer in Gimp as the "Mapped" layer and just blanked out things as I went to keep track of what was done. By mapping things based on major component generally seemed to have worked quite well and I just wrote it all down using pencil and paper as I went. I was considering using Eagle but that is too restrictive. Pencil and paper was just fine for this - I could erase, make long meandering traces, then for a few sections, I just took 2 minutes to re-write it on a fresh sheet with everything laid out nicely once I knew what was there.

I've never traced out a board like this, so was kind of flying blind on what was the best method. I started by tracing the mains circuit in since that was easiest; and was able to isolate the DC bus that comes off of it. Then I moved over to each of the 8-pin DIP ICs and traced everything that connected to them. One of the last pieces was the transistors and MOSFETs. I kept one layer in Gimp as the "Mapped" layer and just blanked out things as I went to keep track of what was done. By mapping things based on major component generally seemed to have worked quite well and I just wrote it all down using pencil and paper as I went. I was considering using Eagle but that is too restrictive. Pencil and paper was just fine for this - I could erase, make long meandering traces, then for a few sections, I just took 2 minutes to re-write it on a fresh sheet with everything laid out nicely once I knew what was there.

I posted the .xcf (gimp) image file down below if anyone wants the high-res with circuit traces.

Physical Board layout

This PCB is a single-sided board which uses entirely through-hole components. The date codes on basically everything I can find are from 32nd week of 2008 (0832). There were a fair amount of jumpers to get signals over traces, but not too crazy. The board is about 1.2mm thick and surprisingly doesn't appear to have any sort of conformal coating. The light enclosure is sealed up generally quite well but is by no means at any sort of wash-down grade. It is higher than NEMA 3R but probably not by much. One thing is does have is lots of layers. The overall signal housing backing is one-piece, and the front side has the black 'hood' that sticks out and does a decent job of diverting water away from the components. Then the light enclosure sits inside of that and has a rubber ring-gasket. So rain isn't likely to get inside and reach the PCB.

I also noticed that there really doesn't appear to be any consideration of clearance/creepage for mains-level voltage. The diode bridge puts Line and Neutral within 1mm of each other.

There are 9 rows of LEDs with the different control circuits laid out in-between. The designers also packed in 5 LEDs tightly on the left- and right-most edges where the LEDs through the middle of the rows were spaced farther apart. Part of the light enclosure 'sandwich' is a color filter and a Fresnel lens. Ever since embarking on this project, I've paid a lot more attention to the exact lumen distribution around an individual traffic signal and they all seem to be really even - not brighter or darker at the edges. So between the additional light and the use of the lensing, the designers seem to have created a very even pattern of light. I can't detect any of the 9 LED rows - it just looks like an even color across the light.

Oh - this is also quite large. The full traffic light itself is almost four feet tall and the light is almost 9 inches across.

As part of this teardown, I learned a lot about power factor correction as the main IC on here is a PF correction chip. It functions like a fancy voltage regulator but ensures that it doesn't disturb the grid waveform too much.

Circuit layout

I'll break this down roughly the same way I traced the circuits. Schematics are in images below this section.

Power rails: Mains voltage comes in and passes through some inductors and a common mode choke before going into the diode bridge. After the diode bridge we have the usual bulk caps and a DC voltage of about 98.6VDC for the primary DC bus. This feeds a secondary DC bus that is generated via a voltage divider and a Mosfet (Q3) to enable/disable the rail. It looks like they're using a Zener diode as part of the feedback loop on the Mosfet. The secondary rail was measured at 15.15V DC. This secondary bus seems to primarily run the control circuits. The primary DC bus is run through the transformers which end up putting out 83V on the secondary side to power the LED bank. (more on the transformers down below - they're part of the PF correction circuit) So there are four different power rails just to run a stop light... This seemed like a pretty intense power supply section but read on and it will make more sense...

LED array: The LED array is the most obvious part of the board. This uses a combination of series/parallel LEDs in one large chain going down through the entire light. The LEDs are powered from the PF Corrected rail at 83VDC. There are five LEDs in a parallel bank; which is then connected in series to the next bank of 5 LEDs. There are 37 total banks of 5 for a grand total of 185 LEDs. This light is a yellow one, so the LEDs are yellow. It also has a yellow color filter as part of the housing. At the end of the array there are two current-limiting resistors (labeled "RA" and "RB") in series that end on GND.

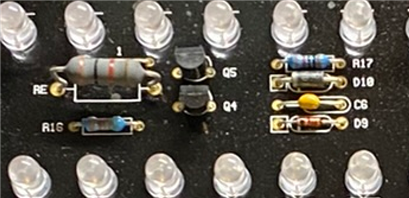

Variable Load section: At the top of the board, there is a large resistor ("RE" top left in the image here) between the PF corrected DC rail and ground; controlled by a transistor/Mosfet pair. I believe that this is used as part of either a 'trimming' circuit to load down the rail or as a dummy load to make the LED light look like an incandescent one to a controller circuit. This is controlled ultimately by the PF correction chip and a feedback circuit elsewhere (bottom of the LED array between the LEDs and the resistors).

Variable Load section: At the top of the board, there is a large resistor ("RE" top left in the image here) between the PF corrected DC rail and ground; controlled by a transistor/Mosfet pair. I believe that this is used as part of either a 'trimming' circuit to load down the rail or as a dummy load to make the LED light look like an incandescent one to a controller circuit. This is controlled ultimately by the PF correction chip and a feedback circuit elsewhere (bottom of the LED array between the LEDs and the resistors).

Transformers: There are two transformers on the board; controlled in parallel. The take in the primary DC bus at 98VDC and output 83VDC to power the LED circuit. They are switched on and off by a large mosfet on the output of the PF correction chip. They also have an extra set of coils that goes to the 'zero current detection' input of the PF correction chip. This picture shows the yellow transformers and a bulk electrolytic cap on the left side which powers the LED bus.

Transformers: There are two transformers on the board; controlled in parallel. The take in the primary DC bus at 98VDC and output 83VDC to power the LED circuit. They are switched on and off by a large mosfet on the output of the PF correction chip. They also have an extra set of coils that goes to the 'zero current detection' input of the PF correction chip. This picture shows the yellow transformers and a bulk electrolytic cap on the left side which powers the LED bus.

Piggy Board: This was an interesting section of the board. There is what appears to be a spot for an expansion card which is unpopulated. They label it as "piggy board". It has connections to the following (their silkscreen followed by my definition)

Piggy Board: This was an interesting section of the board. There is what appears to be a spot for an expansion card which is unpopulated. They label it as "piggy board". It has connections to the following (their silkscreen followed by my definition)

- Primary DC bus (98VDC)

- R-Sin (multiplier input of PF chip)

- VP (LED+ voltage 83VDC)

- GND (DC gnd)

- VN (LED- between the last LED and the CL resistors)

- Q3B (Q3 base - which controls the second DC bus of 15VDC)

- VCC (15V DC bus)

- INH (Goes to Q2 base which in turn can shut off Q3 and disable the light)

I'm not entire sure what the expansion board would be for. It could be for manufacturing to easily test the voltage rails; but not sure why Q3 or Q2 exist since they provide a local override to disable the light. I know that emergency vehicles use a special transmitter; and traffic control devices have a receiver. That setup is used to force-override a traffic signal so that a police, ambulance or fire truck can get through. But in terms or architecture; that receiver would never be inside the light itself - they are mounted above the light stack or on the arm that holds the light above the road. The image on the left shows what they look like. Each intersection would have one facing each traffic direction, and it would just run down to the control box. The only thing that's needed to control the light is to cut mains voltage. So again; not sure why two local overrides are present. See this article for more info.

I'm not entire sure what the expansion board would be for. It could be for manufacturing to easily test the voltage rails; but not sure why Q3 or Q2 exist since they provide a local override to disable the light. I know that emergency vehicles use a special transmitter; and traffic control devices have a receiver. That setup is used to force-override a traffic signal so that a police, ambulance or fire truck can get through. But in terms or architecture; that receiver would never be inside the light itself - they are mounted above the light stack or on the arm that holds the light above the road. The image on the left shows what they look like. Each intersection would have one facing each traffic direction, and it would just run down to the control box. The only thing that's needed to control the light is to cut mains voltage. So again; not sure why two local overrides are present. See this article for more info.

Soooo.... not sure if "piggy" refers to "piggy back" or a slang term for police officers...???

Power Factor Correction chip: I'll do my best here... The chip is a MC33262. See the image on the right. The PF chip is in Yellow. Op-Amp in Red. Mosfet and part of a transformer in Green. This chip in essence reads the voltage and current of the load and can help modulate an output which is used to generate the output voltage which drives said load. I think I could oversimplify it as a kind of voltage regulator. It's main output is switching the large mosfet which powers the transformers to generate the LED voltage rail of 83VDC. It takes in a 2V feedback signal on the bottom end of the LED array which it brings internally and compares with an internal 2V reference. Varying the output mosfet on-time would provide the modulation required to keep the 2V constant. It is also tied to a dual op-amp IC which is used to modulate the variable load section.

Power Factor Correction chip: I'll do my best here... The chip is a MC33262. See the image on the right. The PF chip is in Yellow. Op-Amp in Red. Mosfet and part of a transformer in Green. This chip in essence reads the voltage and current of the load and can help modulate an output which is used to generate the output voltage which drives said load. I think I could oversimplify it as a kind of voltage regulator. It's main output is switching the large mosfet which powers the transformers to generate the LED voltage rail of 83VDC. It takes in a 2V feedback signal on the bottom end of the LED array which it brings internally and compares with an internal 2V reference. Varying the output mosfet on-time would provide the modulation required to keep the 2V constant. It is also tied to a dual op-amp IC which is used to modulate the variable load section.

Here is a link to the chip's data sheet: https://www.onsemi.com/pdf/datasheet/mc34262-d.pdf

I had looked up the patent mentioned by the back cover of this module (5,636,057) which had to do with dimming LEDs. I'm not entirely sure how it applies here other than knowing that LEDs intensity (brightness) is relative to the amount of current put through them. I suppose this circuit would want to monitor that instead of just blasting them with all the current they'll take.

In the process of looking that up, I found this patent which seems to have a 'waste' current (aka dummy load) so that an LED signal uses the same power as an incandescent. I suppose there is a use case where a signal control system would look for burned out lights by measuring current. This may be the use case of what I have labeled as the 'variable load' section on my light.

And even more interesting was this one which talks about specifically actively modulating the current such that the LEDs have a constant lumen output given a wide range of power input. This means that the light will always be visible in broad daylight even if the power line sags. It also discusses shutting down half the array of LEDs so that the second half of them can still be at full brightness in extreme cases. My light only has one single LED string so that wouldn't apply to it.

Thermals! Santa was nice enough to get me a thermal camera for Christmas, so I took a peek at the board. I have a Hikmicro BL1 which streams over wifi to my phone. I found that the two series resistors at the bottom of the LED array get quite toasty, as do some TVS clamping / flyback diodes on the transformer switch. Most the rest of the board was pretty mundane. A biasing resistor as part of the variable load section also gets a bit toasty.

Schematics

Here are the schematics that I traced out.

| {gallery}Traffic Light Schematics |

|---|

|

Power input: Mains input, filtering, and diode bridge to get the primary DC bus |

|

LED Array: LED array also showing series resistors and the 2V reference signal tap. |

|

Variable load: My guess here is that this is used to fine-tune the voltage rail that feeds the LED array... Or to provide a larger load to appear more like an incandescent bulb. |

|

Transformers: DC+ is the primary 93VDC rail; and this is switched to ground by the PF chip on the other side of the primary. The secondary coils generate the 83VDC bus for the LEDs and feed the zero current detect of the PF chip. Not 100% sure i've drawn these correctly for primary/secondary side but they ohm out according to what is here. |

|

Q2 - local disable: Q2 transistor base is brought out to an expansion board pin and can be used to shut down Mosfet Q3 which is the voltage source for the PF chip; which would disable the light. |

|

Q3 - Poor man's voltage regulator: This seems to use a voltage divider and a zener to create the second DC power rail of 15 VDC. |

|

Power Factor Controller: This is the chip that does all the magic. It is connected to all other components on the board and can be disabled by use of either Q2 or Q3 switches to cut off the 15V VCC supply. |

|

Op Amp: This dual op-amp is used to control the variable load section based on an output from the PF chip. The note at the bottom can be ignored. It was from before I had started measuring things. |

Conclusions

After reversing engineering this, and especially after seeing those patients, things started to make sense to me. Power factor correction may not be required on a single light; but multiply that by the hundreds that are installed and running across cities and it starts to make sense. Having a constant light level output given the wide range of input power and dirty power is a must. I'm also assuming that these LED versions are engineered to be 'drop in replacements' for incandescent bulbs from days gone by, so some other accommodations had to be made. Traffic lights are something that billions of people rely on daily and if they falter, it can be a life-or-death situation.

Oh - and the power factor that I measured on this light was 0.99 on my Kill-a-Watt.

Here is a video walk through of the board and enclosure.

If you're still here then you must be really interested - so I have also provided a video as I walk through the schematics and what each section does. This is walking through the 8-page schematics that I drew up.

That's all!