Hello everyone,

In this blog, I would like to briefly describe how I will be using the current sense amplifier module to detect the anomaly in the drone. At various throttle levels, the current consumed by the motors will change, and any hindrance to the propeller or damage to the propeller will result in different current values as the load on the propeller will change hence increasing or decreasing the torque thereby resulting in the change in the current consumption. These subtle variations can be picked by the current sense amplifiers and can report the same to intelligent devices like raspberry pi or a microcontroller. Drones have increased over time due to leading technological advancements in the miniaturisation of electronics, composite materials, machine learning and vision algorithms, and battery technology.

They are everywhere: Drones are now used in agricultural automation, surveillance, photography, logistics, organ delivery, operation and rescue missions and a wide variety of research.

Quadcopters and multirotor: Most drones are multi-rotors like quadcopters, hexacopters etc. fixed-wing drones are very less and are used mostly for military surveillance due to their long endurance. Conventional quadcopters are highly inefficient by design and need a lot of power to hover and travel because they will be pushing air against gravity. In order to fly against gravity, it should push a commensurate amount of air.

Quadcopters are special: But what makes quadcopters stand out is their agility to move and manoeuvre in tight spaces and capability of hovering at a point. This is quite difficult for regular fixed-wing drones. Staying at a point in free space helps you to record wonderfully stable videos and take stunning photographs of building in aerial view and many more things.

But they are dangerous: In order to hover or fly against gravity brushless motors with very high RPM(revolutions per minute) are used in drones. These brushless motors are fitted with propellers which are razor-sharp so that they can cut through the air experiencing very less air friction. This makes the whole system very dangerous as there are 4 very sharp blades spinning at 11000RPM with a Li-Po (Lithium Polymer) battery which can overheat and explode midway so this kind of system needs continuous care or health monitoring in order to work properly. Manual inspection of propellers is not enough as any break in the propeller can lead to fatal injury to drone pilots and people nearby.

So predictive maintenance of drones is an essential thing in this technology-driven world. Another main thing is that this module can be directly used for the predictive maintenance of industrial machines also. Just by training the data of different levels of current consumption.

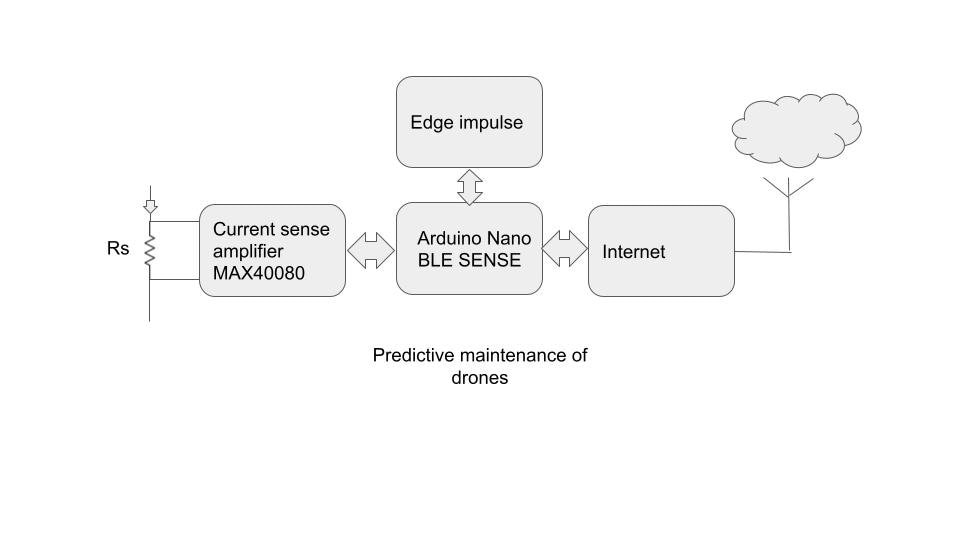

Block diagram:

As per the above block diagram, we need to interface the current sense module with an Arduino Nano and then

send the data to the data-forwarder of the edge impulse. We will collect various samples for various cases such as

a) Broken propeller

b) No Propeller

c) Normal operation

d) Unfastened motor

etc.

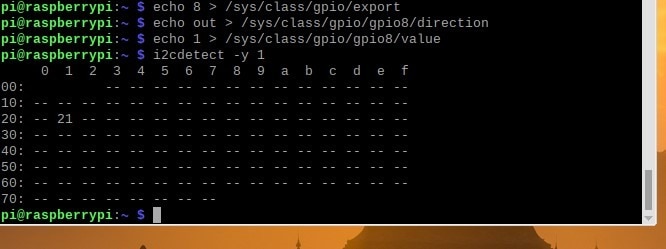

In the beginning, I started using the raspberry pi and through the address scan, I found the address of the

pico click current sense module as 0x21 but when I headed over to interface the raspberry pi with edge impulse,

there was a surprise. Raspberry pi data forwarder for edge impulse is not supported. So I'm using a microcontroller to send the data to the

edge impulse and then using that to train our models.

Raspberry address scan

Data forwarder not supported on raspberry pi

In my 3rd blog, I will be explaining the method to record the data using the data forwarder and how to deploy the same on the

microcontroller and ultimately we will send the data back to the raspberry over USB or MQTT.