I was looking for a suitable stand to hold the MAX25405EVKIT PCB as shown in the picture on the main contest page.

While I was going through the documentation on Maxim's website, I found that they have provided the stl file for the stand so I decided to use the same and 3D print the support structure. Available for download here: MAX25405 IR Gesture Sensor with Lens for Automotive Applications | Maxim Integrated

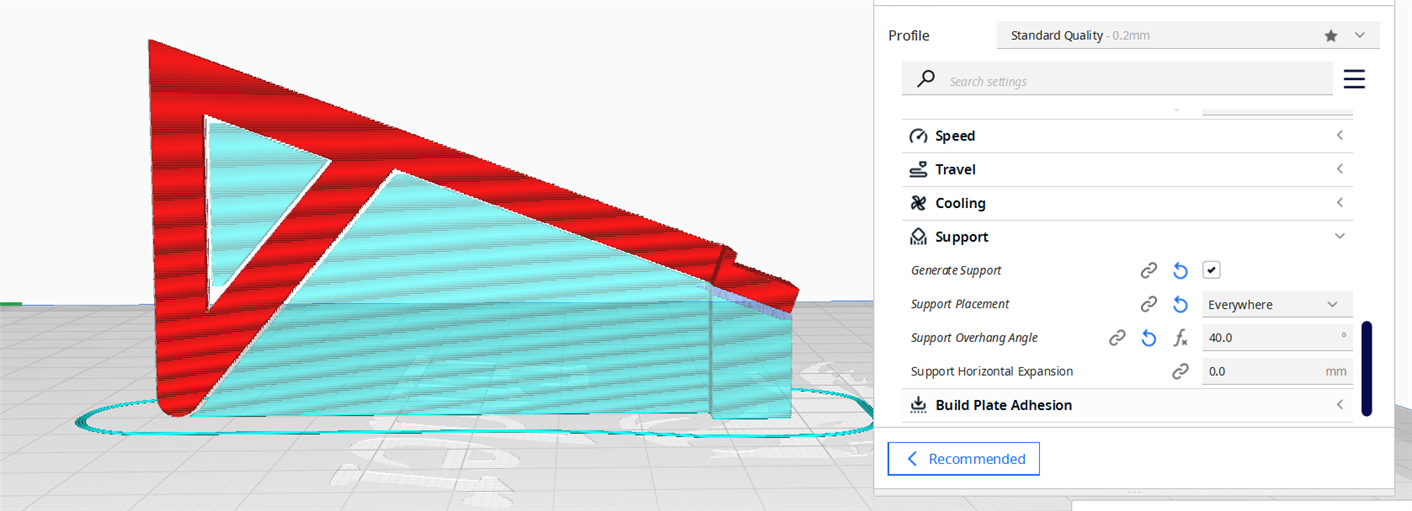

Upon opening the stl file in slicing software (I use Ultimaker Cura) this is how it looked

My smart brain tried to rotate the model 90 degrees to the left and then use support structures to print it however, it failed. The layers being all horizontal and the long arm also being horizontal resulted in a weak structure and it broke easily while I was removing the support structure. Lesson learned, print it the way it was provided by Maxim.

This is the orientation I tried to print it in.

I was successful in printing it but...

While removing the support structure the stand broke apart in two pieces. It was very weak and easily breakable. Hence, I decided to reprint it in the same orientation as given by Maxim.

Here is the sliced stl with support structure. The default setting in Cura has a 45 degree angle for supports. Upon slicing with 45deg. support it does not cover the entire structure, so I lowered the angle to 40 deg.

I have used white PLA+ for printing the stand.

Here are my settings for the 3D printer -

Temp. 200 deg C

Layer height 0.2mm

Other setting default except for the support angle

This is at 45 deg. support. Notice the empty part in between

This is at 40 deg support angle

It took me about an hour and 20 mins to print this and the results were much better than my previous print. I could easily break the support structure without breaking the actual stand and it was quite sturdy as compared to previous one.

The stand with support removed -

The stand already has a hole for mounting the PCB.

I used two small screws to mount the PCB onto the stands.

Here's the PCB mounted on the 3D printed stand -