What is Experimenting with Industrial Automation?

Industrial Automation uses electrical, electronic, and mechanical components to automate industrial processes and machinery. In this competition, participants will receive an extensive kit of components from Schneider Electric. They will use the kit to explore, showcase, and experiment with components in industrial automation systems.

The element14 Community would like to thank our sponsor, Schneider Electric, for providing the industrial automation kits and support.

Grand Prize: kmikemoo

Training Bay Ventilation Automation

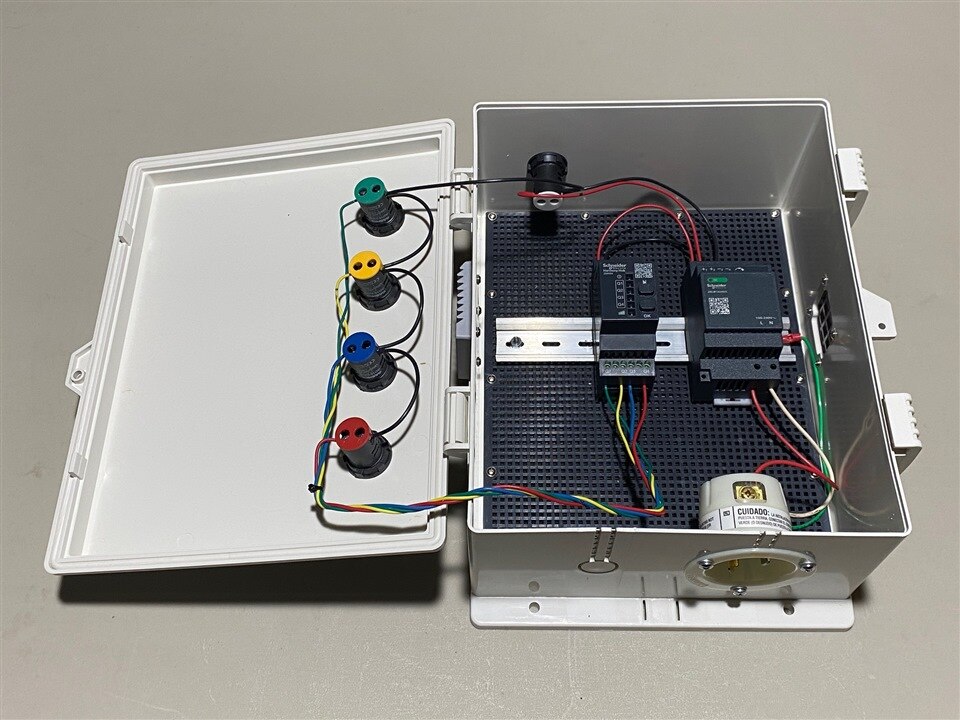

My project plan for this challenge was to improve the control system of the industrial exhaust fan that we use in our training bay, not only to control the heat in the space, but to also extract the exhaust gasses that are generated when propane and natural gas engines are run indoors as part of the generator training. The training bay is 60 feet wide and 100 feet long. The rear bay is 60 foot wide and 20 foot deep and houses the 3 foot diameter vertical exhaust fan. There is a little problem in getting to the exhaust fan control. You may also be able to tell that the top half of the walls are clad in metal sheeting. This will definitely have an impact on any wireless communication that I wanted to add. Fortunately, Schneider Electric has provided a solution in the form of a relay antenna. Not pictured, but mounted on the North wall, are some Bitcoin miners. They generate a lot of heat. We use the exhaust fan to extract that heat. Previously, I installed a thermostat to automatically control the exhaust fan. So now you know the current setup. For the challenge, I want to control the ventilation fan (ON/OFF) from a station by the door leading from the training bay to the classroom. Of course, this location is as far from the current control location as it can be. Fortunately, the switches in the Challenge are wireless - so it's going to be much easier than it would be otherwise. Check out the experiments

My project plan for this challenge was to improve the control system of the industrial exhaust fan that we use in our training bay, not only to control the heat in the space, but to also extract the exhaust gasses that are generated when propane and natural gas engines are run indoors as part of the generator training. The training bay is 60 feet wide and 100 feet long. The rear bay is 60 foot wide and 20 foot deep and houses the 3 foot diameter vertical exhaust fan. There is a little problem in getting to the exhaust fan control. You may also be able to tell that the top half of the walls are clad in metal sheeting. This will definitely have an impact on any wireless communication that I wanted to add. Fortunately, Schneider Electric has provided a solution in the form of a relay antenna. Not pictured, but mounted on the North wall, are some Bitcoin miners. They generate a lot of heat. We use the exhaust fan to extract that heat. Previously, I installed a thermostat to automatically control the exhaust fan. So now you know the current setup. For the challenge, I want to control the ventilation fan (ON/OFF) from a station by the door leading from the training bay to the classroom. Of course, this location is as far from the current control location as it can be. Fortunately, the switches in the Challenge are wireless - so it's going to be much easier than it would be otherwise. Check out the experiments

|

|

Runner Up Prize: pandoramc

Automation Conveyor for Industrial Processes

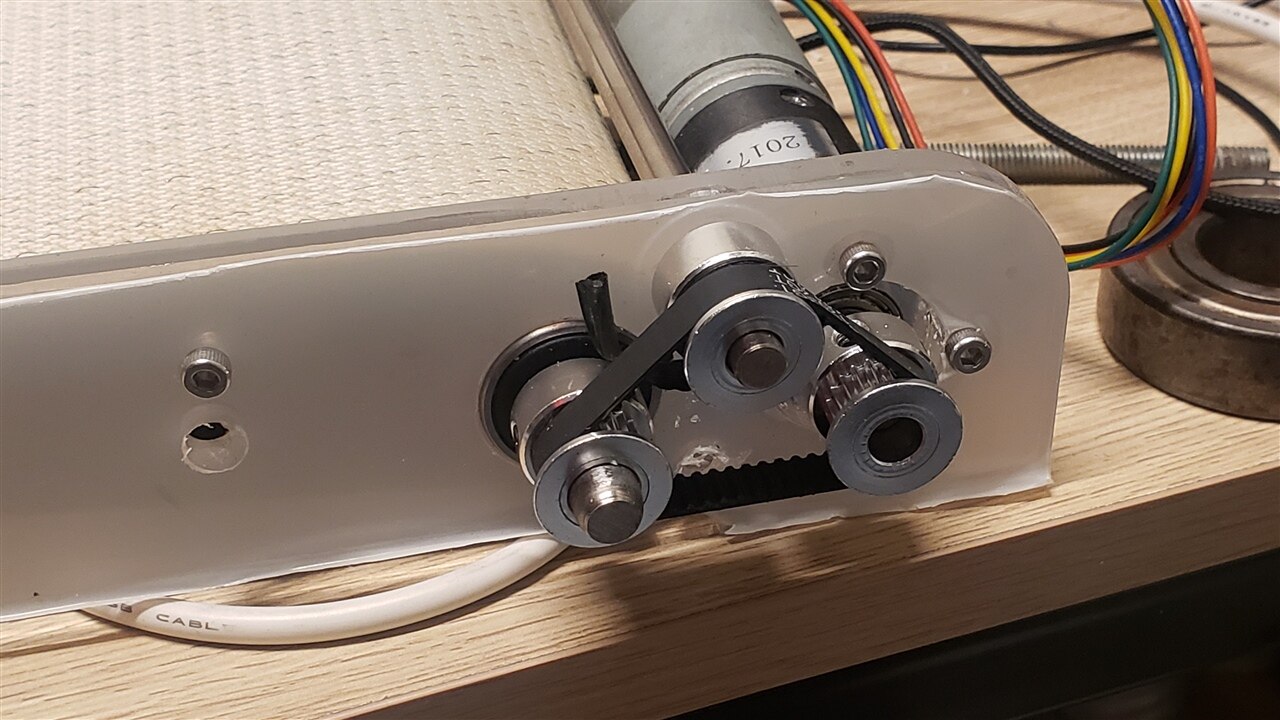

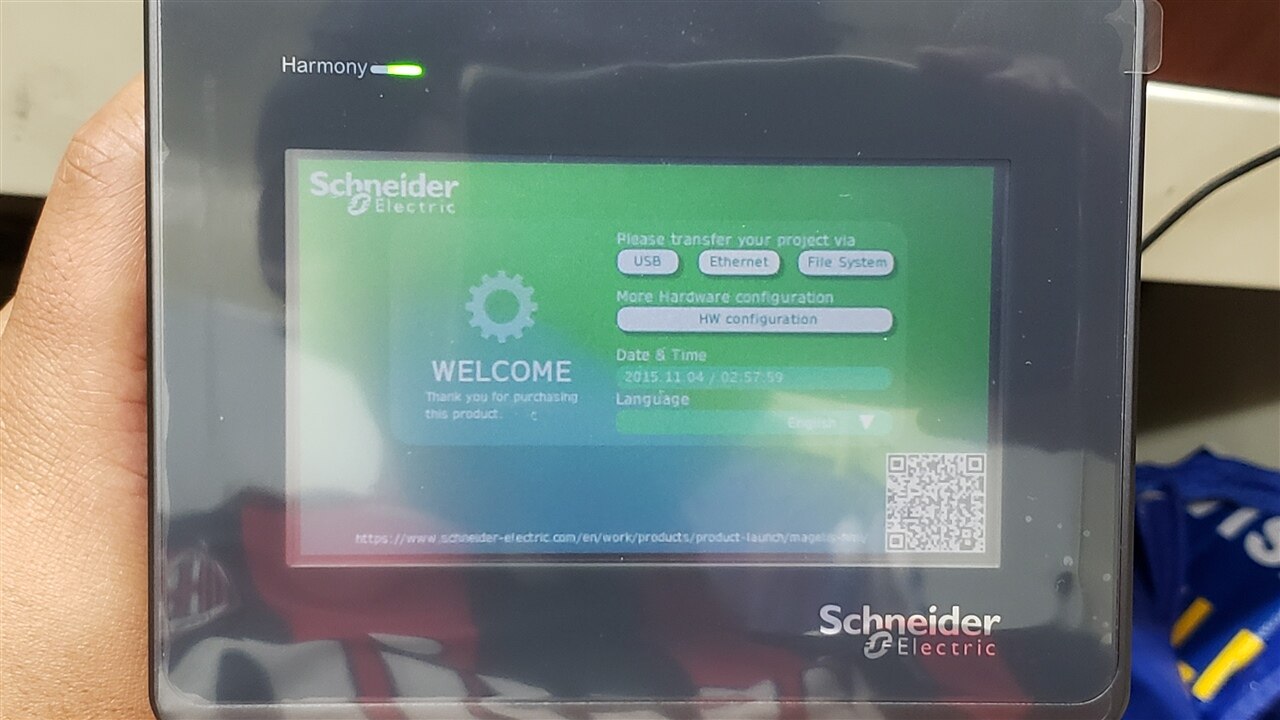

For this challenge, I decided that I would use the Schneider Electric Challenger's kit to build a control system for a conveyor. I started with a proof-of-concept for a conveyor roller implementation. I have a 3D printer to manufacture all the solid or objects that cannot be acquired with the specifications required. Then, I began designing the process to control. To integrate the Schneider Electric components, you only need the power supply, the TM3DM24R connected with the M251 by the expansion port and an Ethernet wire to upload the latest program. The software required to design the logic is the EcoStruxure Machine Expert and I used an external Button to implement a toggle switch. In order to extend the capabilities of the Schneider Electric industrial architecture I added the Harmony Hub to the project. The EcoStruxure Operator Terminal Expert allows the design of user interfaces for the interaction between the operator and the controlled machine. The M251 is really impressive device because all the communication can be centralized and managed in the PLC itself. The Harmony Hub, in cooperation with the M251, offers a new way to connect the industrial facilities, and provide security for the device connectivity. Check out the experiments

For this challenge, I decided that I would use the Schneider Electric Challenger's kit to build a control system for a conveyor. I started with a proof-of-concept for a conveyor roller implementation. I have a 3D printer to manufacture all the solid or objects that cannot be acquired with the specifications required. Then, I began designing the process to control. To integrate the Schneider Electric components, you only need the power supply, the TM3DM24R connected with the M251 by the expansion port and an Ethernet wire to upload the latest program. The software required to design the logic is the EcoStruxure Machine Expert and I used an external Button to implement a toggle switch. In order to extend the capabilities of the Schneider Electric industrial architecture I added the Harmony Hub to the project. The EcoStruxure Operator Terminal Expert allows the design of user interfaces for the interaction between the operator and the controlled machine. The M251 is really impressive device because all the communication can be centralized and managed in the PLC itself. The Harmony Hub, in cooperation with the M251, offers a new way to connect the industrial facilities, and provide security for the device connectivity. Check out the experiments

|

|

|

Third Prize: embeddedguy

Overhead tank monitoring

Water is an important resource. Research often finds that water is not used effectively. Several liters of water are wasted every hour throughout the world. To overcome this challenge, technology can be of help to us to automate the task of tank filling in the home or in industry. For this design challenge, my project was to create a project for overhead tank liquid level monitoring. This means the project can be useful to monitor water level in the tank inside house. But these system could also be used to monitor other liquids and chemicals in industry.

Water is an important resource. Research often finds that water is not used effectively. Several liters of water are wasted every hour throughout the world. To overcome this challenge, technology can be of help to us to automate the task of tank filling in the home or in industry. For this design challenge, my project was to create a project for overhead tank liquid level monitoring. This means the project can be useful to monitor water level in the tank inside house. But these system could also be used to monitor other liquids and chemicals in industry.

Every house has two tanks. One is in the basement where water comes from the central facility such as dam or reservoir. Another one is up on the terrace that gets filled by tank in the ground floor using a motor. See left image below which diagrams the system. T1 is overhead tank and T2 is the tank at ground floor. Thus, the system uses a water level sensor on the overhead tank, which controls the motor accordingly. More sensors can be added in another tank in the ground floor, as needed. This can reduce the manual work and hassle to remember to turn ON/OFF motor switch. In turn, automation will save water if user forgets to turn off the motor if the tank is filled to required level thereby saving water. Check out the experiments

|

|

|

The Challenge Kit

| Product Description | Buy Kit |

|---|---|

| ABLM1A24025 Power Supply | Buy Now |

| TM251MESE PLC | Buy Now |

| HMIST6200 HMI | Buy Now |

| ZBRA1 Signal repeater | Buy Now |

| ZBRA2 External antenna | Buy Now |

| ZBRT2 Transmitter Module | Buy Now |

| ZB5AZ009 Collar | Buy Now |

| ZB5AK1233 Wireless Selector Switch | Buy Now |

| ZB5AW333 Push button | Buy Now |

| ZBRN2 Modbus Hub | Buy Now |

| ZBRRH 4 PNP Outputs | Shipped |

| ZBRV1 Visual Feedback Module | Shipped |

| 782XBXM4L-24D Power Relay | Buy Now |

| 70-782D8-1A Relay Socket | Buy Now |

Other Participants

- rahulkhanna - Smart Factory Automation System

- rsc - Water Tunnel Controller Upgrade

Element14 Community would like to thank Don Bertke and Shabaz for judging the Experimenting with Industrial Automation Challenge!

Top Member: DAB

Don spent 35 years in the aerospace industry working on many advanced projects. His range of experience covers nearly every scientific field and most ranges of the electromagnetic spectrum. He has a very broad interest and knowledge in science with extensive analysis in image, multispectral and hyper-spectral analysis. He has also worked on a wide range of embedded computer applications, including integrated search and rescue systems.

Top Member: Shabaz

Shabaz has studied Electronics Engineering followed by Law, and worked primarily in the fields of radio communications (military), telecommunications (infrastructure used by phone companies), data networks, and information technology. He was originally involved in hardware design, followed by software engineering and technical marketing.

![]() About Schneider Electric

About Schneider Electric

Our purpose is to empower all to make the most of our energy and resources, bridging progress and sustainability for all. We call this Life Is On. Our mission is to be your digital partner for Sustainability and Efficiency. We drive digital transformation by integrating world-leading process and energy technologies, end-point to cloud connecting products, controls, software, and services, across the entire lifecycle, enabling integrated company management, for homes, buildings, data centers, infrastructure, and industries. We are the most local of global companies. We are advocates of open standards and partnership ecosystems that are passionate about our shared Meaningful Purpose, Inclusive, and Empowered values. http://se.com

-

dougw

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

kmikemoo

in reply to dougw

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

kmikemoo

in reply to dougw

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children