Table of Contents

- Overhead tank monitoring for smart home/industry

- Experimenting with industrial automation is challenge from element14 and schneider electric that challenges members of element14 community to create projects or experiment with task of industrial automation such as painting, cutting, industrial robotics control or task such as remote monitoring of sensor data and control of different devices such as motors, pumps or any modern industrial equipment.

- Why I decided to take part in this challenge?

- Why overhead tank monitoring important for house/industry?

- Traditional electronics & technology to monitor tank level

- '

- Introduction to the Experimenting with Industrial automation kit

Overhead tank monitoring for smart home/industry

Experimenting with industrial automation is challenge from element14 and schneider electric that challenges members of element14 community to create projects or experiment with task of industrial automation such as painting, cutting, industrial robotics control or task such as remote monitoring of sensor data and control of different devices such as motors, pumps or any modern industrial equipment.

First, I would like to thank Schneider Electric and element14 for choosing me as an official challenger and sending me the official kit bundle.

Why I decided to take part in this challenge?

I have done bachelors degree in Instrumentation and control engineering. In that, I had so many courses and tasks related to automation and control. I have done some courses on PLC, sensors and industrial communication standards such as RS232/485, modbus and fieldbus. The difference between industrial automation devices and embedded systems devices is that industrial devices are more compact and packed. They work on higher power ratings and programming this devices require different kinds of software and programming tools than traditional embedded microcontrollers or microprocessors. For example, PLC(Programmable Logic Controllers) can operate on 24VDC or 240VAC. The programming for PLC is done in different programming language than for embedded systems which usually work on C/C++ or Python programming. PLCs normally are programmed using ladder diagrams, flow charts, instruction lists, structured text etc. PLC comes with IO modules and common communication bus such as Ethernet, RS485, serial etc. To conclude, for industrial automation or automation in general it is quite suitable to use specific devices that are designed in this kind of form factor.

Why overhead tank monitoring important for house/industry?

Water is an important resource. It provides way for humans to survive on the planet earth. Water is useful to grow crops on the field and for us we use it for drinking everyday several times. In fact, human body is made up of around 70% of water. Several research states that water is not used effectively. Several litters of water is wasted every hour throughout the world. To overcome this challenge, technology can be of help to us to automate the task of tank filling in house or in industry. This can reduce everyday's manual work and hassle to remember to turn ON/OFF motor switch. In turn, automation will save water if user forgets to turn off the motor if the tank is filed to required level and save the water by dropping from the tank outlet.

Every house has two tanks. One is in the basement where water comes from the central facility such as dam or reservoir. Another one is up on the terrace that gets filled by tank in the ground floor using motor(submersible or simple). Image below demonstrate this with simple diagram where T1 is overhead tank and T2 is the tank at ground floor.

For this challenge and the kit it is possible to create a system that implements automation of tank water level. For that a simple design is to use water level sensor on the overhead tank and control the motor accordingly. Additionally more sensors can be added in another tank in the ground floor to automate entire process.

Traditional electronics & technology to monitor tank level

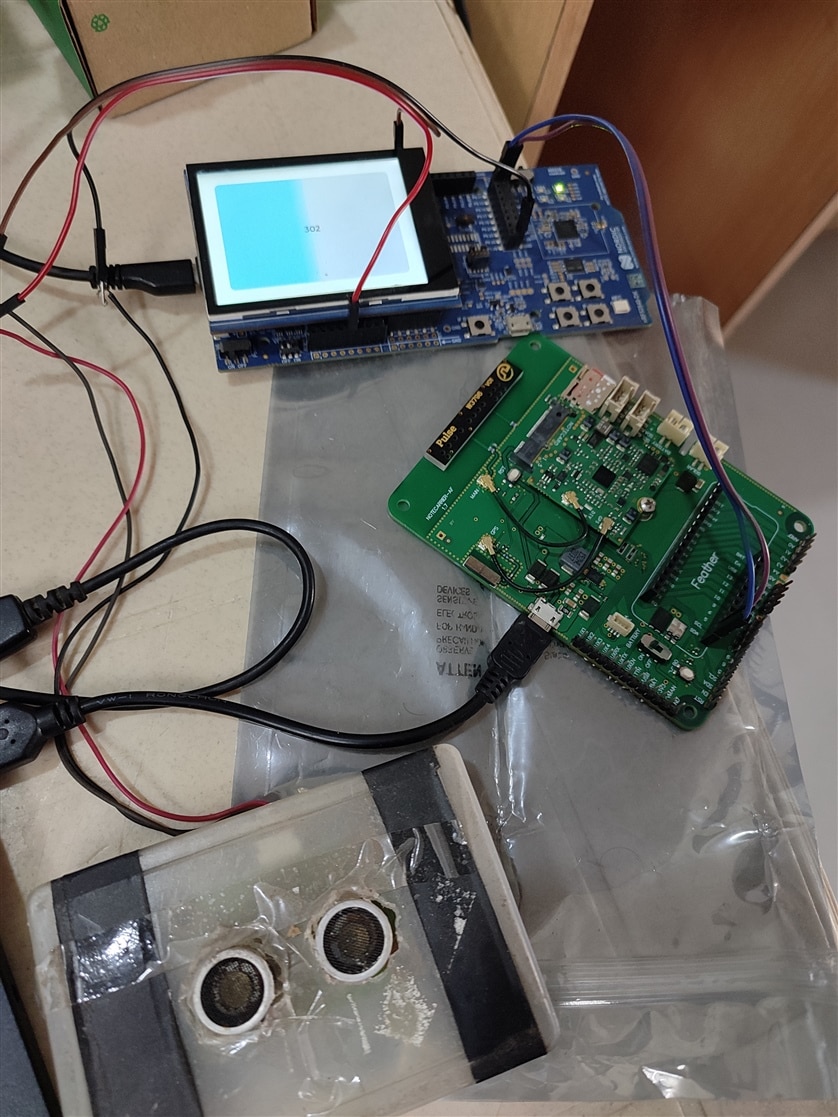

The idea to monitor the water level inside the tank is not new. Previously, I have tried some traditional electronics such as Arduino and 433MhZ RF Tx/Rx modules and some cellular/WiFi technology with cloud connection to visualise the data online. In the next paragraph I will mention each of this project, how they work and what are the possible disadvantages of this projects.

For the first time when I tried this project, it was simple. I used an Ultrasonic level sensor compatible with Arduino. The sensor can detect level in the range of 0 to 4m(400 centimeters). It has the following features.

- Minimum range 10 centimetres

- Maximum range 400 centimetres (4 Meters)

- Accuracy of +-1 cm

- Resolution 1 cm

- 5V DC Supply voltage

- Compact sized SMD design

- Modulated at 40 kHz

- Serial data of 9600 bps TTL level output for easy interface with any microcontroller

'

'

The following link details everything about this sensor.

https://www.sunrom.com/download/1166.pdf

The project had 433 MhZ RF module that costs no more than 3$. On the overhead tank there is Arduino compatible microcontroller board and ultrasound sensor measuring the water level. This data was transmitted to receiver side that contains another Arduino compatible board with DS1307 LCD display. The setup worked for some distance but failed to provide enough range. Hence, I created a wire antenna to increase the range. The range increased successfully but still there are some drawbacks to this system. One of them is that 433MhZ RF module is not suitable considering RF interference from similar module operating nearby. There are chances of receiving wrong data. Also it poses security risk if there is automation based on this data. To conclude, this setup is only useful to display the sensor data(i.e. water level) and with the condition that no other module is operating nearby at same frequency.

The next setup(that I am currently also working on) is using Blues wireless notecard. Notecard provides cellular/WiFi connection to the cloud Notehub.io from where data can be sent to different cloud platforms for visualisation or decision making. Cloud platform API's can be used for making decisions. Response can be sent from cloud to device back to take actions such as turn off the motor. I am using Ubitdots platform as preferred cloud. Again as with above setup, this project also has limitations. First, it would require active SIM card and cloud connection. secondly any failure in network or on device may lead to missing a deadline or entire failure of system.

Considering limitations and disadvantages as mentioned above, it could be a good idea to experiment with industrial automation. PLCs and other industrial devices can be of use where it is more simple to program the device. These devices also support different voltage levels and they have more capable CPU instead of microcontrollers.

Introduction to the Experimenting with Industrial automation kit

Fortunately, experimenting with industrial automation official kits contains everything that is useful to create a prototype implementation of Overhead tank monitoring. On the official challenge page, all the devices that are shipped are mentioned. The page also mentions official challengers, their projects and progress.

The kit contains following major parts from Schneider electric.

- 24 VDC power supply

- A PLC(modicon M251)

- HMI module Harmony ST-6200

- Harmony XB5R ZBRN2

Along with this parts the kit has antenna, switches and push buttons, relay modules and some other minor parts. The following images are of unboxing the official kit.