Table of Contents

Input/Outputs

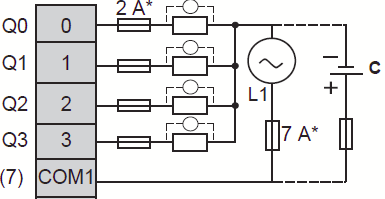

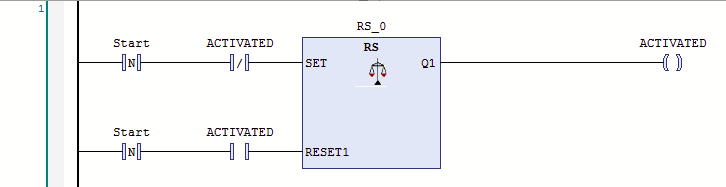

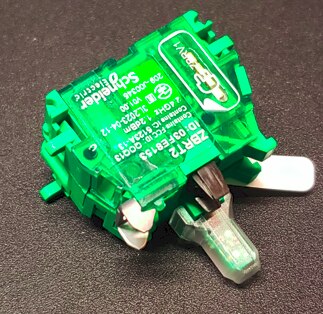

Although the M251 does not have Inputs/Outputs like other series of the PLCs, the device has expansion connectors to improve the capabilities. In this learning path, there was the opportunity to use the TM3DM24R, which is an I/O module. There is an interesting feature in this module, the terminals can be configured with positive logic or negative logic, since the common terminals are not internally connected. On the other hand, to test the operation I implemented a toggle button to turn on and turn off a load each time the button is pressed and released.

| {gallery}I/O |

|---|

|

Expansion Connectors |

|

Positive logic connection |

|

Negative logic connection |

|

Button connected to expansion module |

|

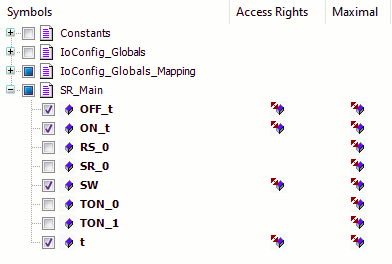

Toggle function synthetized with a SR Flip-Flop |

Interfaces

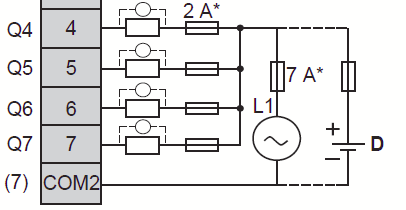

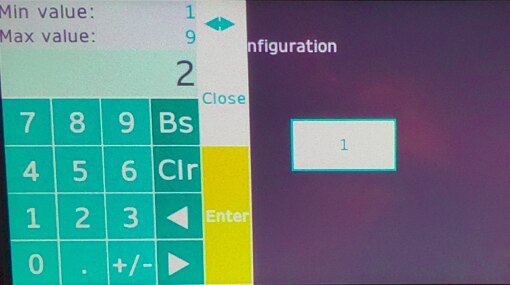

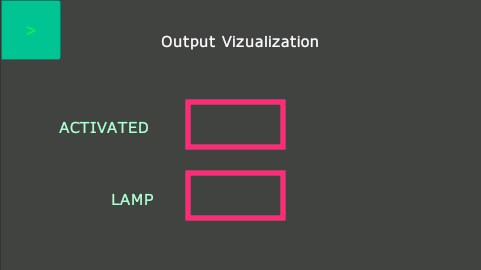

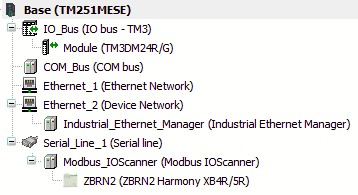

The M251 is really impressive device because all the communication can be centralized and managed in the PLC itself. This is possible because there are two Ethernet connections and a configurable Serial Line. In the chosen architecture, the serial line is dedicated to the Harmony Hub, since the ZBRN2 model has a ModBus protocol through an RS485 serial port. This brings a remote interaction between the buttons and indicators, and avoids the use of other expansion modules. The Ethernet ports were used for the PLC programming and the data exchange with the HMI. Despite its size, the HMI is a powerful tool to interact locally or remote if the Network infrastructure allows that. An interesting feature of the HMI is the red edge coloring when a variable does not exist or the communication fails

| {gallery}Interfaces |

|---|

|

Assembly of visual receiver and a button for the Harmony Hub interaction |

|

Remote placement of the Harmony Hub wireless receiver |

|

Data exchange with the ST6200 |

|

HMI Interaction with the M251 device |

|

Variable connection failure |

Software

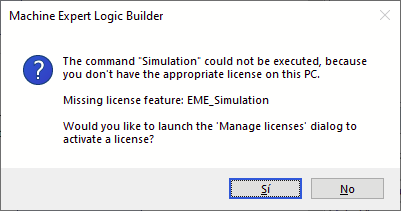

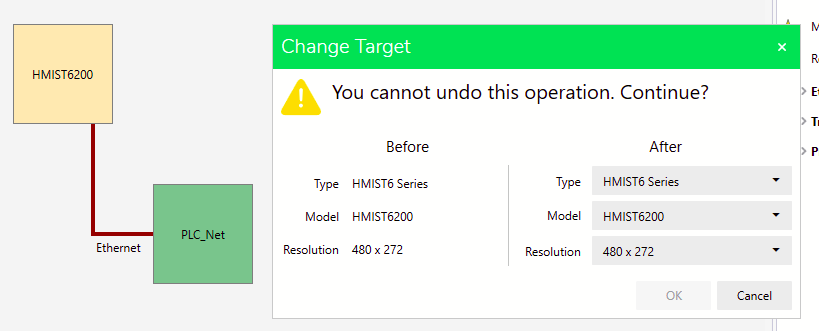

The software is amazing, it is intuitive and we can do a proof-of-concept really quickly. You just have to look at the licensing modes. Despite the Machine Expert has 42 days to test the software for free, you can register yourself on the Schneider Electric website to get a limited license to test and program the PLC. We will lose the simulation benefits to test our applications before the programming, but you are able to use the PLC after this road test. To recover this cabability, you must acquire a license from an SE dealer. Other features may be limited, but for a small scale application the available could be sufficient. On the other hand, if there is not a valid license for the Operator Terminal package, you will not be able to download your program to the HMI, here you MUST get a valid license.

| {gallery}Software |

|---|

|

Limited License effects |

|

Machine Expert Architecture for the proof-of-concept |

|

HMI Project Architecture |

Application

Despite the prototype limitations of the first proposal, it is feasible to understand our weakness and select other elements that can improve the system behavior. An example is changing the acrylic structure for a metal sheet to achieve a better structure that resists the forces involved in the transmission line. The designed roller did not have a treatment to improve the coefficient of friction and the forces could break the acrylic, consequently, the new proposal has this new material.

| {gallery}App |

|---|

|

Roller design with 3D printer |

|

New tensor system |

|

Last roller assembly with the transport belt |

Conclusions

The whole system has interesting features and approaches since the connected industry (IIoT) is an importMachine-human interaction must evolve, and the HMI provided has the flexibility to configure the machine operation according to work conditionsant area of application today. The Harmony Hub, in cooperation with the M251, offers a new way to connect the industrial facilities, and provide security for the device connectivity. Thanks to rscasny

for the support and all the participants for sharing their concerns about the devices in order to solve them.

I added the Toogle function like a Youtube short below