Training Bay Ventilation Automation

First, I would like to thank Schneider Electric and element14 for selecting me to participate in this challenge. I'm excited to participate because, let's face it, the equipment is cool. PLC's, touchscreens, wireless pushbuttons and selector switches. All pretty amazing stuff.

Second, if you watched the video... this is pretty much a repeat of the video. The words have been rearranged so to not be cruel to someone that does check out both.

My project plan for this design challenge is to improve the control system of the industrial exhaust fan that we use in my training bay not only to control the heat in that space, but to also extract the exhaust gasses that we generate when we run propane and natural gas engines indoors as part of generator training.

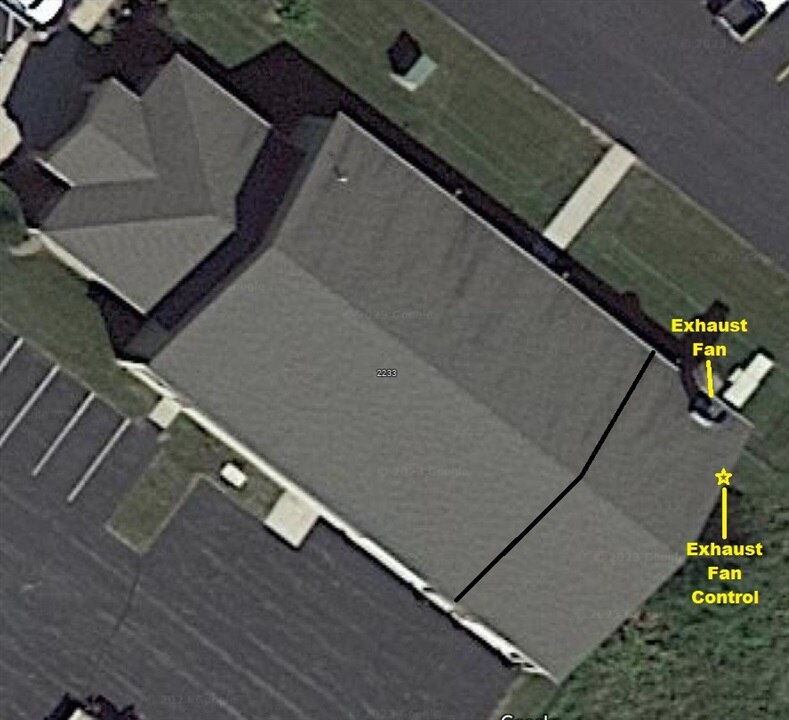

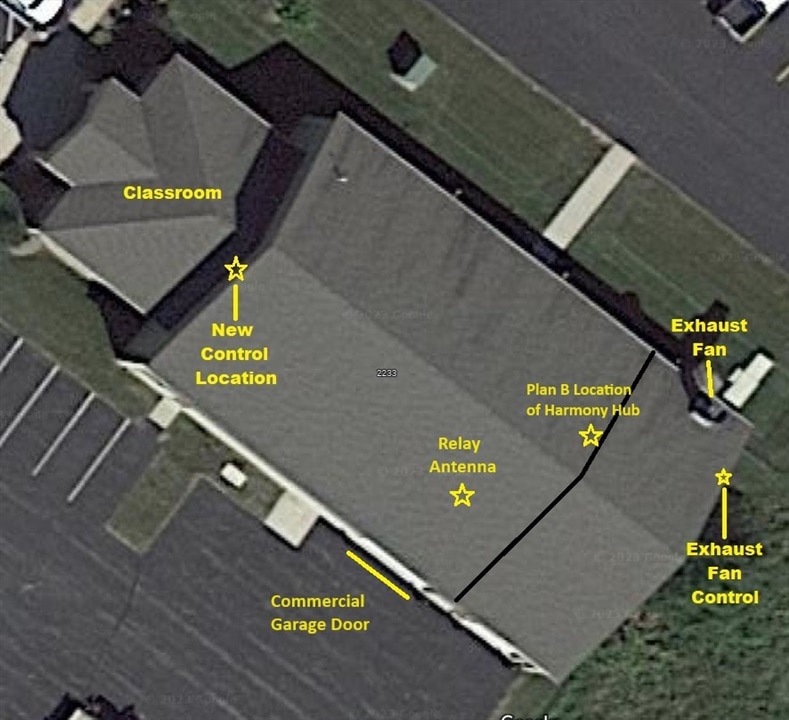

The training bay is 60 feet wide and 100 feet long. The black line in the picture indicates the location of a dividing wall. The wall has a 16 foot wide, 12 foot tall opening in the center to allow access to the rear bay. The rear bay is 60 foot wide and 20 foot deep and houses the 3 foot diameter vertical exhaust fan. This area used to be a paint booth but only the fan portion remains.

There is a little challenge in getting to the exhaust fan control. Let's call it "Executive storage".

The red circle indicates the location of the fan controller. If you think that it looks difficult to get to, it's worse in real life. You may also be able to tell that the top half of the walls are clad in metal sheeting. This will definitely have an impact on any wireless communication that I want to add. Fortunately, Schneider Electric has provided a solution in the form of a relay antenna. The relay antenna will go slightly to the left of the garage door opener (3rd picture) so as to have a straight shot to the fan controller location.

Not pictured, but mounted on the North wall, are some Bitcoin miners. They generate a lot of heat. We use the exhaust fan to extract that heat. A while back, I installed a thermostat to automatically control the exhaust fan - and that capability must remain in addition to any new capabilities. See Pi Pico in Industrial Fan Control.

So now you know the current setup. For the Design Challenge, I want to control the ventilation fan (ON/OFF) from a station by the door leading from the training bay to the classroom. Of course, this location is as far from the current control location as it can be. Fortunate for me, the switches in the Design Challenge are wireless - so it's going to be MUCH easier than it would be otherwise.

I would also like a “Ventilate NOW” pushbutton in case the carbon monoxide detector goes off. This feature would not only turn the fan on but would also open the the large garage door in the bay. The fan would remain ON until reset at the control panel near the fan.

So the project plan is to put an ON/OFF switch and a pushbutton switch by the classroom door.

Place the communications module and PLC at the current control location.

Place the relay antenna as stated above.

I'll run hard wire from the garage door opener to the PLC. The opener is a 24VAC circuit so I will use an interposing relay to signal OPEN.

I will integrate the local pushbutton station.

And finally, add back in the thermostat.

If the communications don't work as planned, Plan B is to move the communications module to the separating wall and hard wire to the PLC. I've got plenty of Cat5 to use up.

Not included in the video is my plan to add in an indicator light station. This will be portable - because one of the components (ZBRRH) is a wireless output module and, well, because it can.

Once that works, the stretch goal is to find a way to integrate a carbon monoxide detector into the system so that the “Ventilate Now” button is a backup. Again... automation.

AND... if anyone is concerned about this application needing Safety Circuit rated equipment, the warning thresholds that we use are well below needing Safety rated equipment. While I have personally set off the carbon monoxide detectors, we have never set the alarm off during a training class. That "Don't try this at home" knowledge has to come from somewhere... but carbon monoxide is not to be trifled with. It's why we have the detectors in the first place.

So... that's the plan. I hope you'll join me for this challenge and maybe even be inspired to create a super cool application of your own.

-

javagoza

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

javagoza

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children