RTC module supercap modification

One of easiest to build supercapacitor applications could be a modification of Arduino RTC module. Some of least expensive ones are based on DS1302 RTC chip and are usually equipped with CR2032 battery socket.

Given that DS1302 consumes about 1uA of current when left alone, installed battery would last for very long time - so proposed modification can be justified in some specific situations (for example: temperature range outside of battery's specifications or some sort of sealed module, without possibility of battery replacement) or as supercapacitor evaluation setup.

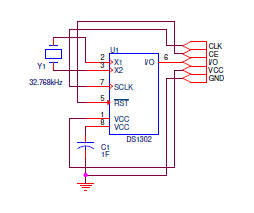

Module schematics is very simple - it contains only three elements (ic, oscillator and battery/supercapacitor):

and proposed modification involves desoldering battery socket, modifying traces for supercapacitor (if needed) and solderting a capacitor - in this example 1F, 5.5V one

DS1302 has battery charging circuit builtin that is disabled by default and protected from accidental enabling. Full list of available charger configurations include (connected in series):

- 1 Diode, 2kΩ

- 1 Diode, 4kΩ

- 1 Diode, 8kΩ

- 2 Diodes, 2kΩ

- 2 Diodes, 4kΩ

- 2 Diodes, 8kΩ

When using DS1302RTC library it can be turned on using following command sequence, which configures it as one diode connected with 2kΩ resistor circuit:

RTC.writeEN(1); RTC.writeRTC(DS1302_TRICKLE, 0xa5); RTC.writeEN(0);

Installed supercap is about twenty years old Panasonic EECRF0H105 EDLC (or - to be more precise - series connected supercapacitor pair), salvaged from some old server motherboard, that was planned to be used as test case of long-time parameter retention (pair is chosen during manufacturing process to have similar parameters to not exceed maximum voltage of weaker capacitor - so it would be interesting to check if it is still true after many years of work), but it seems that the construction is more sturdy than expected (not only shrink-wrap but also a metal case) so access to individual cells would be rather difficult:

As a supercap can be thought of as series of capacitors with different series resistance, process of charging and discharging can be long - for example, in the circuit above, after initial charging and disconnecting (leaving only running RTC chip), 1V (from 3.97V to 2.97V) decreased after 16h (equivalent of 17uA discharge current).

Then, during 7h of charging, voltage increased to 4V and after next 72h to 4.27V (about maximum given than charging circuit includes series connected diode).

Next discharge period lasted 12h and decreased voltage to 3.82V (equivalent discharge current of 10uA).

After another 4 days of charging, equivalent discharge current dropped to several uA - which indicates how long it will take to fully charge such a capacitor.

Supercap powered model car

As for every component, supercapacitor needs proper design to give good results. In this point I would like to show some not-so-good design decision, resulting in suboptimal supercapacitor performance. Some time ago I have bought a DIY kit that looked like this:

Using this kit, one could build solar-powered toy car, designed to promote sustainable lifestyle (where car is charged when connected to a charging station shaped like a home with PV panel roof). Unfortunately, real life performance is bad - after sitting in full sun for several minutes, wheels start to turn slowly, giving a car very limited range when released.

Inside a car there is a small DC motor and a 3.3F supercapacitor:

And charging station contains a small PV panel:

It turns out that the problem is with charging process performance - when charged using constant current of 200mA (with voltage limit of 2.2V), wheels start to turn very quickly after a short time and after a minute or two charging current drops to about 40mA and stays this way - it seems that this is current consumption of the running motor. After 2 minutes of charging, motor runs for about 5 minutes - much better than when charged using provided PV panel.

Trying to estimate how much power we can get from installed PV module (with no datasheet available) we can do some simple math:

Assuming peak Sun irradiation at 1000W/m2 and panel's area of 0.000828m2, we will get at most 0.828W of input power. As our panel looks like a budget one, we can assume that it has efficiency in the range of 10%, resulting in current in the range of 40mA at 2.1V - comparable with motor power consumption, so the charging process is very slow, giving the toy bad performance (at least in places with moderate Sun irradiation levels) - some motor disconnector during charging would be really helpful (or - better yet - bigger panel).