Experiments on the propagation of heat #1

Introduction

My name is Carlo Russo and I am a computer engineer. Since I was a boy I love to spend my free time with electronics and I like to play with both analog and digital electronics.

For years I have been a teacher and I have been involved in computer networks and computer architectures.

Very often I try to intrigue my students by showing them how sensors can be important to evaluate the correct functioning of an electronic device and how, sometimes, by reading the values obtained from the sensors and interpreting them intelligently, it is possible to carry out the preventive maintenance that detects problems when they are still in their initial state and therefore allows technicians to act preventively, before a failure occurs and forcing us to stop a service, even an important one of the company, in order to be able to repair or replace an hardware component.

This contest interests me because it is an opportunity to show my students the NTC thermistors and show them how they work and how they can be interfaced to a simple board with an analog input.

There are multiple techniques for carrying out preventive maintenance but the most used sensors are thermal and acoustic ones. The latter are used, for example, to understand if moving parts, such as fans or electric motors, are working according to their correct values or if something "unexpected" is happening. The analysis of the thermal state of a system provides very important information, too. Wherever there are movements or powered electrical circuits or mechanical parts in motion, heat is always present. We can talk about the Joule effect or friction but it is inevitable that whatever a system does something, it will heat up.

The thermistors

The thermistors (thermally sensitive resistor) have been known to scientists for nearly 200 years but have had few practical applications due to the difficulty of producing them until 1930.

Thermistors have many features that make them highly appreciated, namely:

- their higher resistance change per degree of temperature provides greater resolution,

- they are highly repeatable and stable,

- they have low thermal mass, so their response to temperature changes is quite fast.

NTC thermistors are used primarily for precise temperature control because they can be manufactured to very tight resistance tolerances and temperature accuracy.

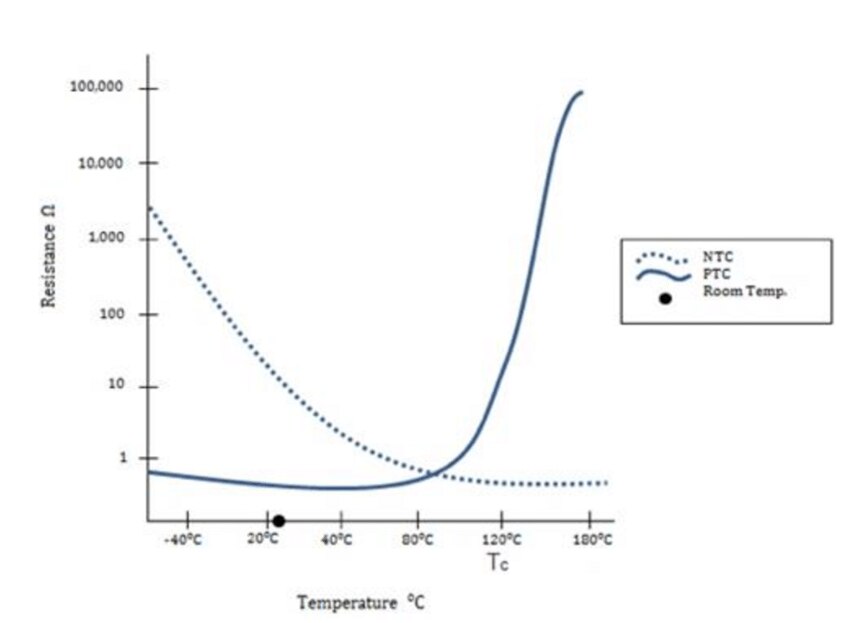

The thermistors can also be used as current limiters (NTC), especially in the starting phases of the systems, when high initial currents could damage or at least put under stress an electronic circuit while the PTC thermistors are used as self-resettable fuses.

Thermistors are nonlinear devices, which means that the points on a graph representing the relationship between resistance and temperature do not form a straight line. As a result, when we use a voltage divider made with an NTC thermistor with a resistance in series, the voltage obtained will not be directly proportional to the temperature, at least not in a wide range of temperatures.

NTC thermistors are usually specified by their resistance at room temperature (typically 25 ° C)

Relatively low-temperature applications, such as -55 to 70 ° C, generally use lower-resistance thermistors of 200 to 10,000 Ohms and higher-temperature applications generally use thermistors with resistance above 10,000 Ohms to optimize the resistance change per degree at the required temperature .

Thermistors come in a variety of shapes, such as disk, chip, bead or rod, and can be surface mounted or embedded in a system. They can be encapsulated in epoxy resin, glass, or baked-on phenolic, or they can be painted. The best shape often depends on what material is being monitored, such as a solid, liquid or gas.

The KIT

The Thermistors kit provided by element14 consists in many (10) different devices in terms of characteristics and shape.

The kit includes:

• 213860-1637 NTC Ring Thermistor

• 213860-2637 NTC Ring Thermistor

• 213862-2637 NTC Ring Thermistor

• 215272-3307. Thermistor NTC, 3892K, 3 Kohm

• 215272-3407. Thermistor NTC, 3892K, 4.7 Kohm

• 215272-3507. Thermistor NTC, 3892K, 5 Kohm

• 215272-3607. Thermistor NTC, 3892K, 10 Kohm

• 215272-3707. Thermistor NTC, 3892K, 12 Kohm

• 215272-3807. Thermistor NTC, 3892K, 30 Kohm

• 215272-3907. Thermistor NTC, 3892K, 47 Kohm

My project

The purpose of this work is to use thermistors in order to have an accurate temperature measurement on a metal surface. The project concerns the study of the propagation of heat on a metal bar.

I'm going to consider a metal bar and apply a heat generator to it. I will then apply thermistors to the bar, at fixed distances from the heat source, to measure the temperature in the various points of the bar in different cases:

- metal bar,

- metal bar with heatsink;

- metal bar with heatsink and dinamic controlled fan.

The purpose of this simple project is to allow students to review some of the knowledge acquired in physics courses and to be able to apply them in the everyday life of a computer technician (eg control of the temperature of a CPU).