Hello to all. I'm kmikemoo and I classify myself as a tinkerer. In my mind, "tinkerer" is the Old World term for Maker, only slightly less skilled. I also think I'm hilarious - despite what people tell me.

I want to thank e14 for allowing me to participate in this Design Challenge. This is actually my first one - meaning that this is the first Design Challenge where I actually thought of an application that fits the challenge. I like knowing how things work but I really like putting them to work. What does it DO?

Up to this point in my electronics journey, I have not done a lot with temperature, humidity... all that weather, atmospheric stuff. Lots of others have done impressive work with those sensors - but I never really saw the need to use them. Until...

A few months ago, the company I work for invested in five Bitcoin and two Ethereum miners. For the battery storage systems that I am testing out, these are great load banks - and they even help pay for themselves. My building really didn't present enough load to demonstrate the battery storage systems. Anyway, my new load banks - really just the Bitcoin miners - put off a significant amount of heat (and noise). NOW I'm interested in temperature. If this were September or later into Winter, the heat would help offset the building heating costs and all would be fine. When it hits 90 degrees F outside... now I'm WORRIED about heat. You have my attention.

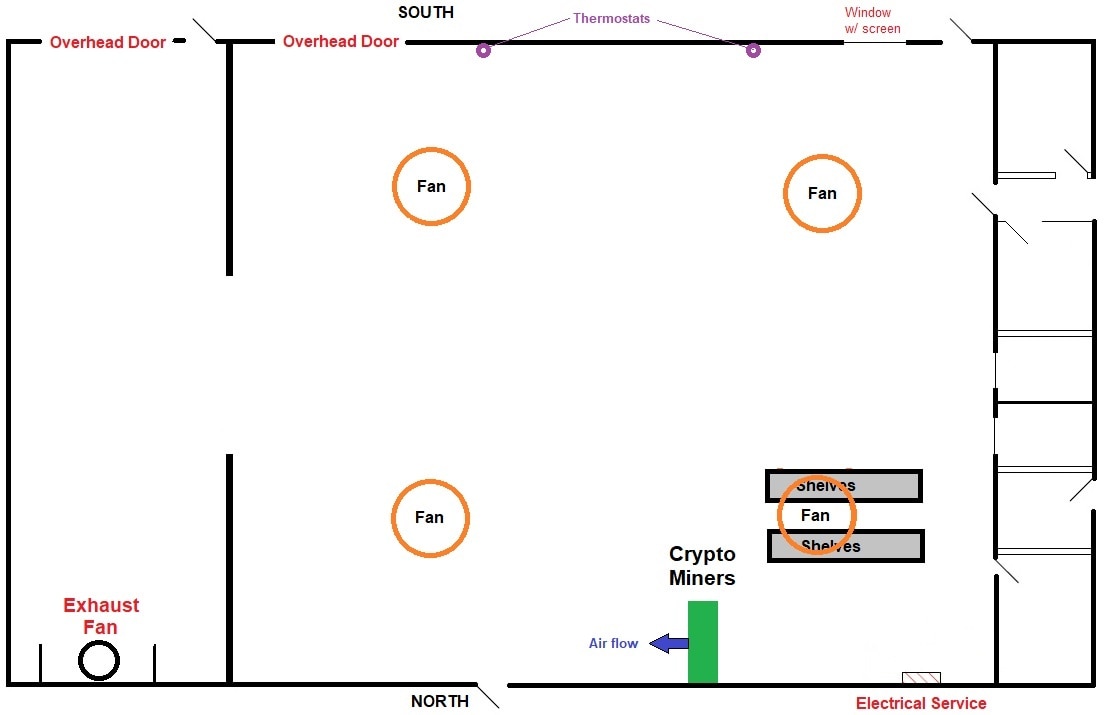

My experimentation plan it to use the thermistors with Raspberry Pi Picos, distribute them around the bay that houses the miners and determine the best method to flow heat from the miners out of the building. I hope to incorporate wireless monitoring on the Picos so I can map the heat more easily. The variables in play are the large exhaust fan in an adjoining smaller bay, two personnel doors and a garage door. We will not be using the door into the air conditioned classroom. That is just not cost effective. It does have influence when all the outer doors are closed and the building is in a slight vacuum. There are also four ceiling fans. There are six small upper windows (18" x 36"). They are fixed windows but I have removed the glass from one and replaced it with screen. Three of the six small upper windows are slated to be upgraded to openable windows with screens, but they are on back-order. I have high expectations that their eventual delivery and installation will not affect this experiment.

What is the path of the heat?

What is the temperature differential across the Bitcoin miners?

Is the temperature differential essentially consistent with a change in ambient or is the discharge temperature more constant?

Do the ceiling fans help or hurt by disrupting the heat flow to the exhaust fan?

Do the different sensors give different readings in the same location?

Am I able to use a temperature sensor to determine if the drive belt on the exhaust fan has broken? (We're on belt #3 in as many months.)

Does opening the personnel door downstream from the miners help mitigate the heat at the miners?

So many questions...

Step #1 will be to assemble the close temperature sensors. The ring terminal sensors will start on PVC poles in the discharge path of the Bitcoin miners one meter from the miner fans. Another set of sensors will be deployed to map how the heat fans out as it leaves the miners. All of the sensors will start at the same height as the ring terminal sensors measuring the discharge temperature. One sensor will be used to record the inlet temperature to the miners.

Step #1b will be to turn the overhead fans off and see how this changes the heat distribution and flow patterns.

Step #2 will be to deploy the sensors to determine the rise of the heat path. There are sufficient things hanging from the ceiling to attach the sensor to and I have access to a scissor lift.

Step #2b will be to turn the overhead fans off and see how this changes the heat distribution and flow patterns.

Step #3 will be to deploy the sensors around the bay, turn off the exhaust fan - just like what happened this weekend during a power outage - and track the temperature rise. I don't know when the power went out, but the exhaust fan does not have auto restart. The ambient temperature was about 70 degrees F, but the thermostats within the building read 94 and 96. I do not know what the temperature was up near the ceiling - where the sprinkler heads are... but we are going to find out. Ordinary sprinkler heads are rated 135-170 degrees F. We are probably getting close to the lower part of the range. This will also be the opportunity to collocate some sensors to determine if they respond the same.

So... that's the plan. In the end, one of these sensors is ending up with a permanent assignment as a high building temperature alarm sensor. This experimenting will allow me to determine the best trigger point. It can't just be 90 degrees F because the building was also 92 when the ambient was 92. Maybe there's a better place to sense the temperature. So many questions...