Sound tube

I'll have to give some credit to beacon_dave again for cajoling me into trying a sound tube to make the ultrasonic sensor more directional. I had been complaining about latency I was getting from trying to use a moving average filter to reduce the multi-path noise that I was getting. I had previously tried a short 30mm tube that I had printed for another project, but I couldn't really see any positive effect.

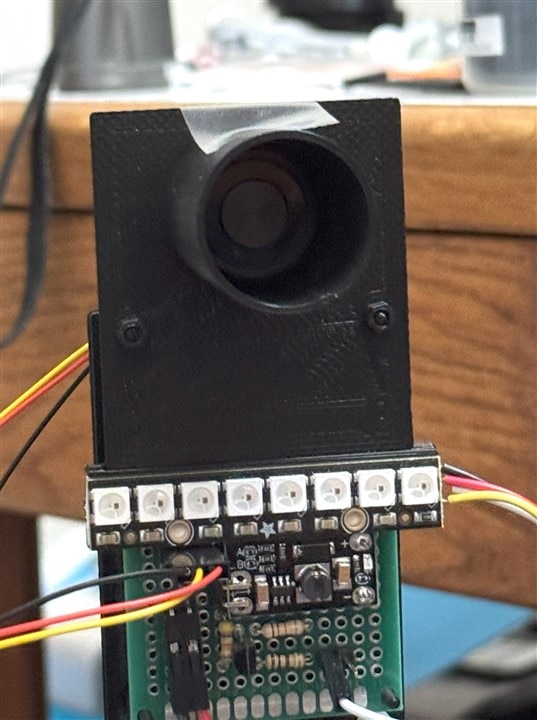

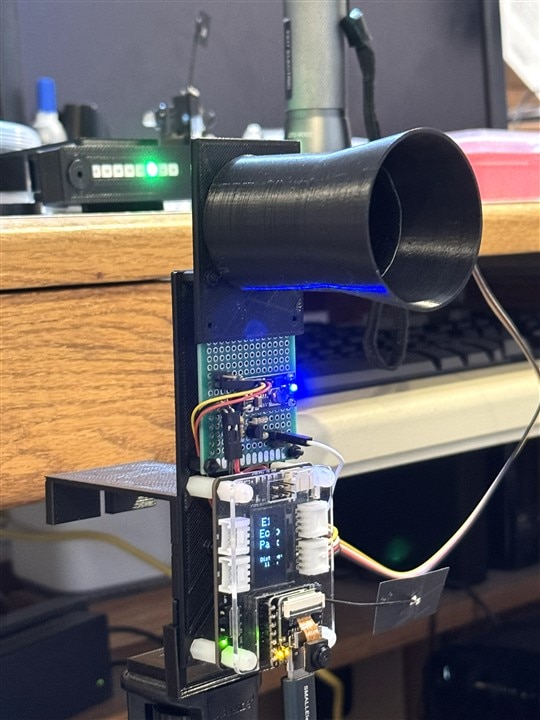

Here it is being used with my ESP32 setup:

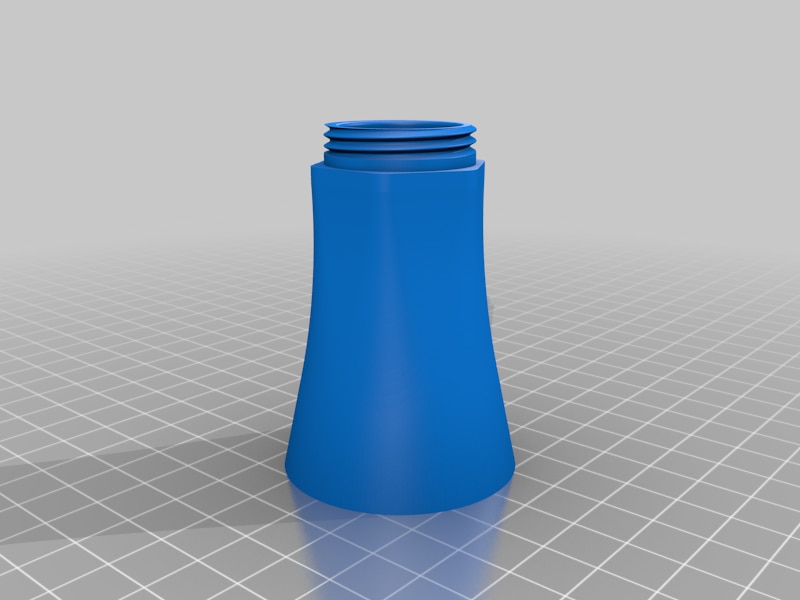

I realized that the best way to get a quantitative look at the effect of a tube would be to use the Demo board with its GUI for quick visualization. It seemed intuitive to me that the tube wasn't going to help much with the transmitted pulse, but would help restrict the angle of the received echoes. I have no idea how I would go about optimizing a sound tube, so I took a seat of the pants empirical approach with the goal of just making the noise "better". Dave had a picture of a long (>300mm) sound "trumpet" that was used on an 80's era ultrasonic tape measure. It is basically a long tapered tube with the small end at the sensor. I've seen sound tubes for PIL Sensors, but they are used only on the short range (400mm), high frequency (360KHz) sensors. I decided to mimic the design of the SR04T - Ultrasonic distance sensor cone on Thingiverse that is designed for a 40KHz sensor.

I ended up trying a 40mm cylinder with a 30mm cone on top as it was quick to design and print.

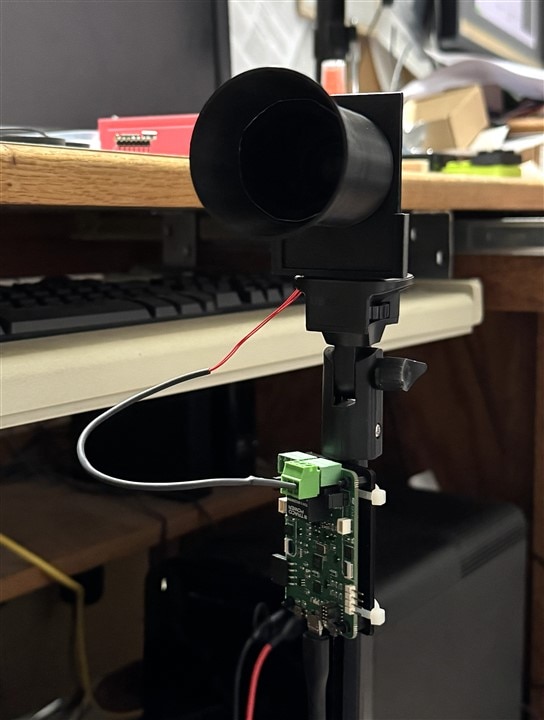

I then printed a new mounting plate for the sensor and here is the new setup (I call it the sound trumpet in honor of Dave ):

Testing

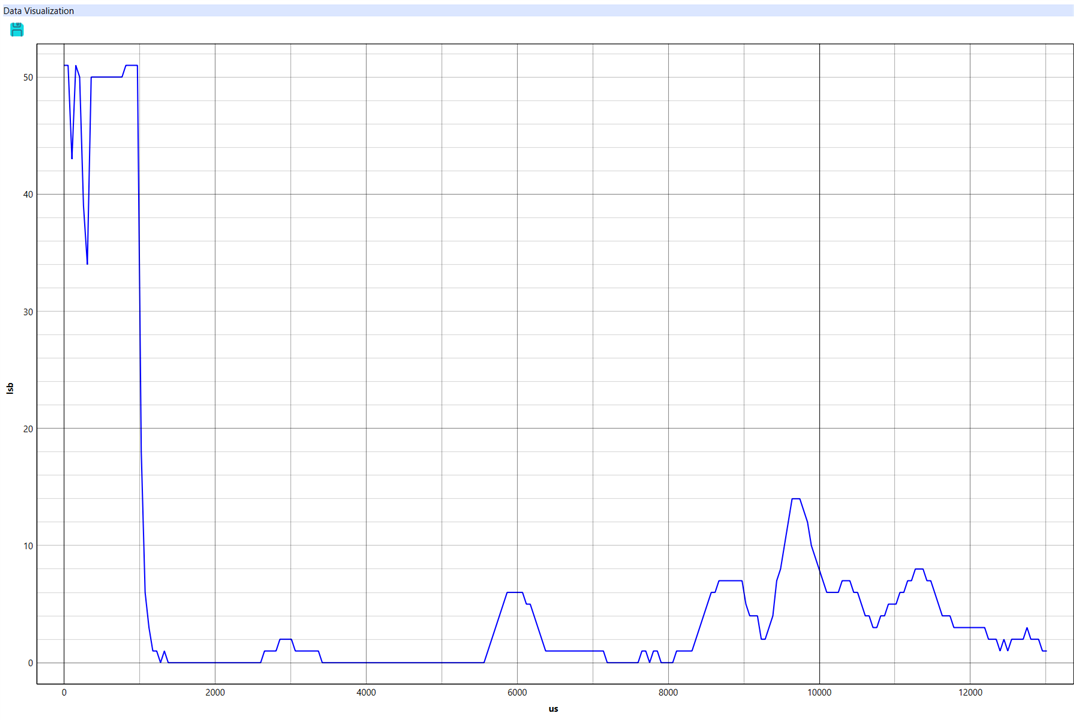

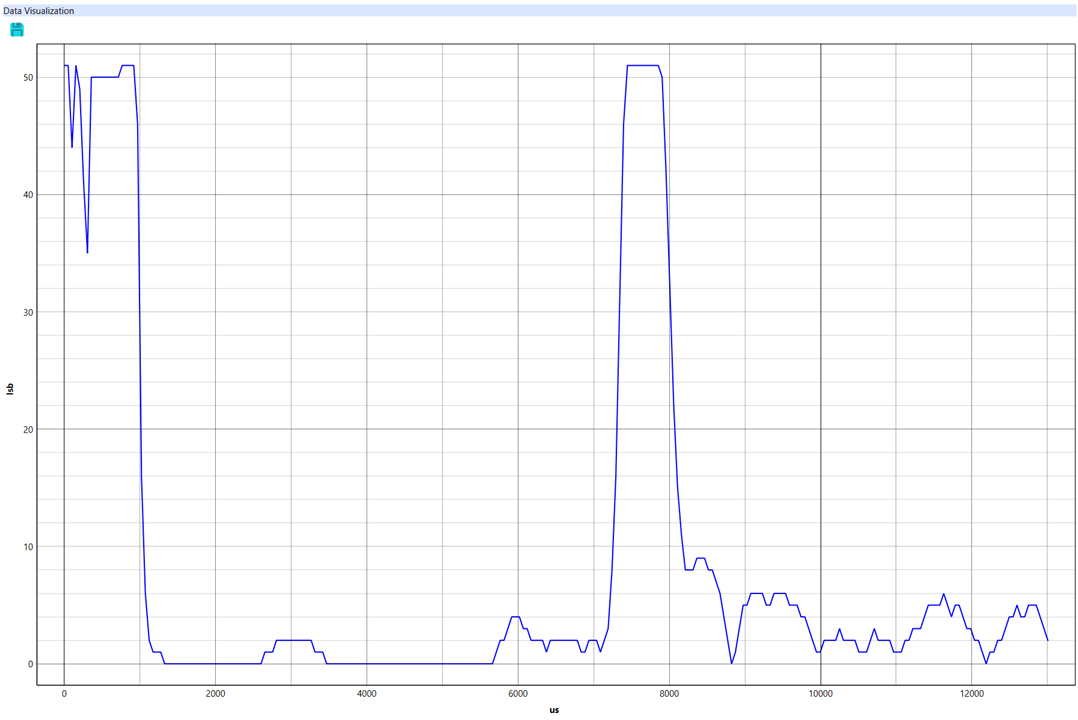

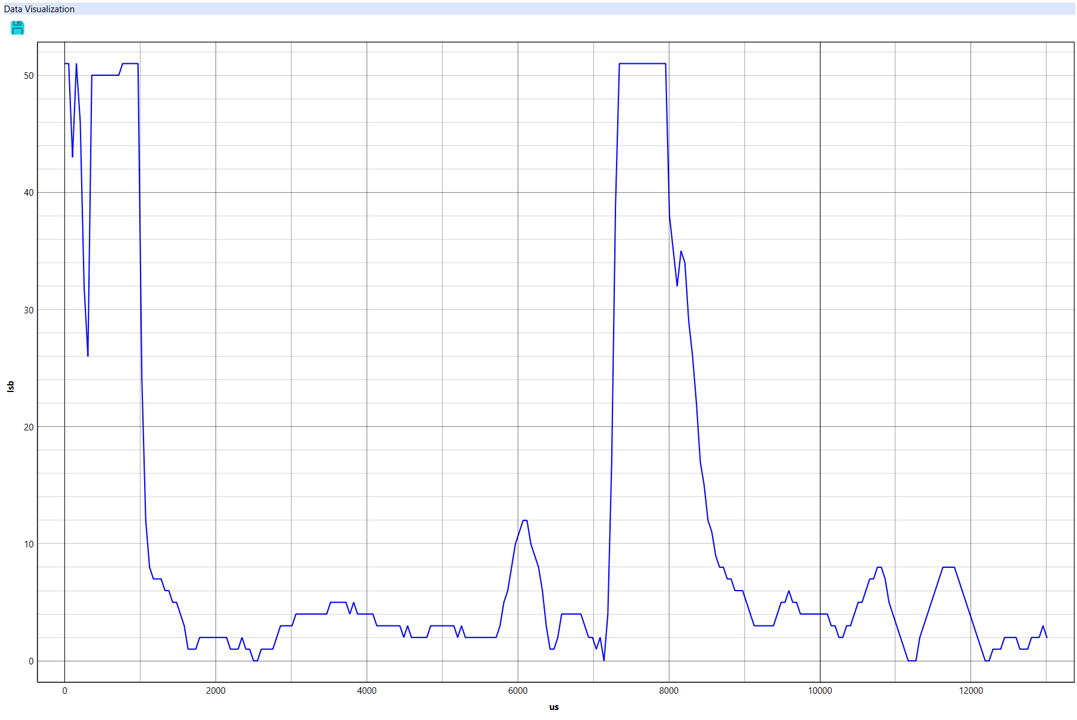

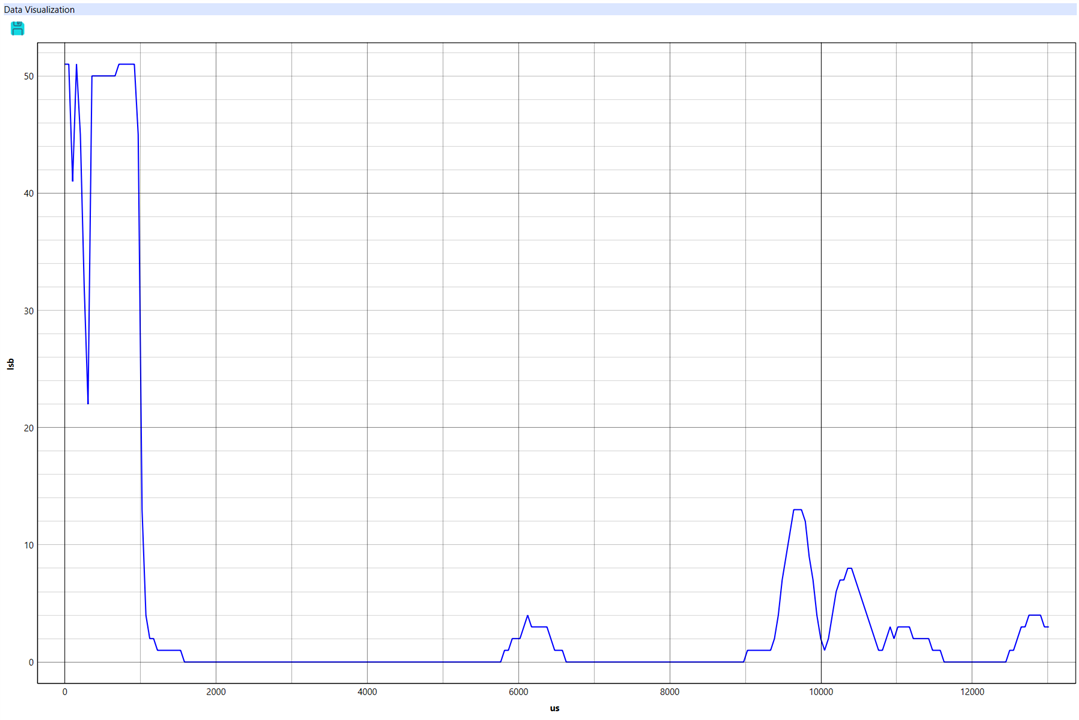

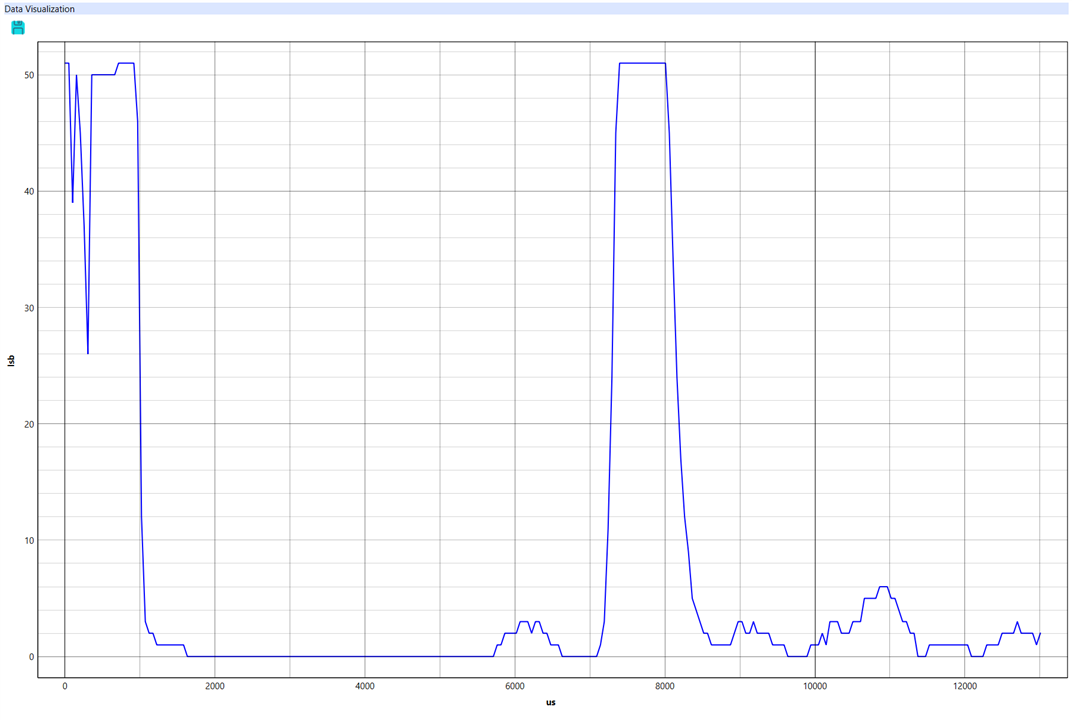

To test the effect of the trumpet, I ran a series of envelope plots:

No trumpet, no target

No trumpet, square panel target at 120cm

Trumpet added, square panel target at 120cm

I'll admit that looking at the envelope data, I couldn't determine that I'd improved anything. It looks like the amplitudes all increased and shifted in time. The primary echo was wider.

What really surprised me was the Streamout readings. Without the tube it was measuring 90cm and with the tube it was measuring 50cm. I was using default thresholds, so I was probably catching the first secondary echo which had more amplitude with the trumpet added.

I had read that it might help to line the tube with sound absorbing material to prevent getting reflections caused by the transmit pulse. So, I tried lining the tube with 1/8" felt that is used for furniture pads.

Re-ran the envelope tests.

Trumpet with felt lining, no target

Trumpet with Felt Lining, square panel target at 120cm

Now, the part that I don't fully understand is the Streamout data now shows 128cm and it is extremely stable (quiet).

I, then modified the thresholds (increased them for near echoes) and Streamout showed 123cm and it was even more stable.

So, I'm extremely happy with the results. I'll need to modify the project setup so that I can use the trumpet and do additional testing in the garage.

Hardware cleanup

I'm in process of cleaning up the project hardware to get ready for final testing.

- Created a separate assembly for the LED strip and buzzer so that they can be mounted above the sensor assembly for visibility (I settled on 50cm above). I rewired things so that the buzzer and Neopixel wires are in the same Grove cable.

- Modified the USSM sensor mount to accommodate the sound trumpet.

- Made shelf mounting brackets for the LED and sensor assemblies.

- Cleaned up wiring.

- Added test points for the sensor level shifter.

- Retested the hardware

Here is the side view of the final assembly with the trumpet and shelf mount. The LED assembly is on the desk in back.

And the front view - you can see the felt lining in the trumpet cylinder.

And the assembly test video.

What's next?

Lots of software integration left. Code became unmanageable, so need to modularize it. And the final garage testing. Many opportunities to break stuff.

And, of course, the Project Blog is going to take a bunch of time...