In my previous blog post, I briefly introduced the concept of utilizing Raspberry Pi as a central control board for various modules. Today, I'd like to delve deeper into one of the fundamental aspects of this idea: the voltage power supply. By harnessing the power of Pulse Width Modulation (PWM) signals and employing a half H bridge, we can effectively manage the frequency and transmit data to other components within the system.

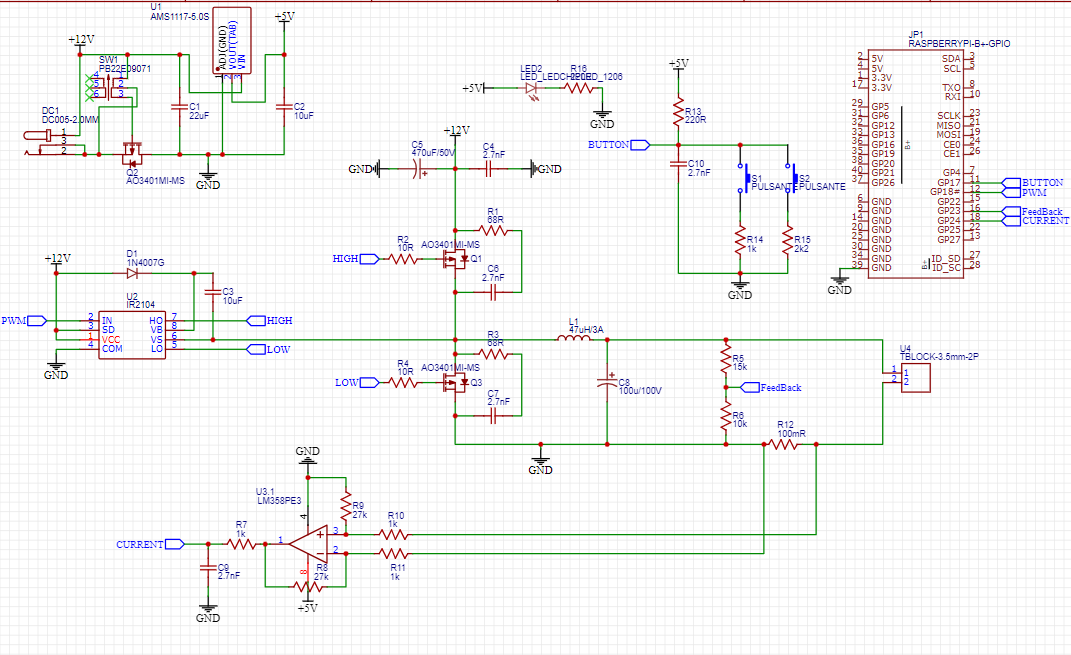

However, it's important to note that this project aims to go beyond mere programming; it involves the creation of a comprehensive electronic device. To give you a better understanding of my design, let me present the schematic diagram.

The schematic diagram serves as a visual representation of the connections and interactions between the various components in our electronic device. It outlines the arrangement of key elements such as the Raspberry Pi, voltage power supply circuit, PWM signals, and the half H bridge module.

At the core of the system, the Raspberry Pi acts as the main control unit, providing the necessary computational power and connectivity. It generates PWM signals to regulate the voltage supply and communicate with the other modules effectively.

To ensure a stable and reliable power source, we incorporate a voltage power supply circuit. This circuit is responsible for converting the input voltage to the desired level required by the components. It also serves as a protective measure, preventing voltage spikes or drops that could potentially damage the connected modules.

By utilizing PWM signals, we can modulate the voltage supply frequency to transmit data to different components within our electronic device. This enables seamless communication between modules and facilitates the smooth operation of the entire system.

To achieve this, we employ a half H bridge module. This module allows bidirectional control of the current flow, enabling us to control the voltage polarity and thus regulate the power supplied to specific components. It acts as a switch, directing the flow of current as required by the system.

Overall, this schematic represents the initial groundwork for our electronic device project. It showcases how the Raspberry Pi, voltage power supply circuit, PWM signals, and the half H bridge module come together to create a robust and versatile system. In future blog posts, I will expand upon other modules and functionalities, demonstrating the full potential of this project.

Let's explain more from the circuit.

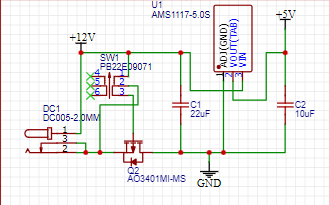

In the schematic diagram, we have included a 5V regulator configuration. This configuration begins with a transistor-based protection mechanism, which safeguards against overcurrent and reversed current situations. By incorporating this protection, we can prevent any potential damage to the connected components.

The purpose of the regulator is to ensure a stable 5V power supply, which is essential for the proper functioning of certain components within the system. By supplying a consistent voltage, we can guarantee the reliability and optimal performance of these components.

Additionally, the regulator serves another crucial function by accommodating other voltage inputs. In situations where alternative voltage sources are present, the regulator can handle the necessary adjustments to provide the appropriate voltage level required by the components. This flexibility ensures compatibility with various modules that may have different voltage requirements.

By incorporating this 5V regulator into our design, we can confidently power additional components, knowing that they will receive the necessary voltage for their operation. Furthermore, its ability to handle different voltage inputs adds versatility to our system, allowing us to incorporate diverse modules seamlessly.

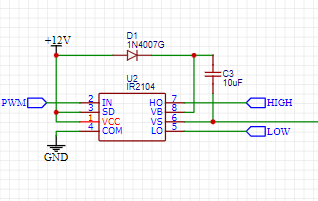

At this point of the circuit, we are making that half h bridge to handle a signal provided by the rasp to operate the voltage when we send some dutty cycle that later will be programmed the IR2104PBF to send the voltage to the rest of the circuits that act as a buck down converter, to keep in mind we can not get higher voltage than provided by the power supply since the configuration is a buck down.

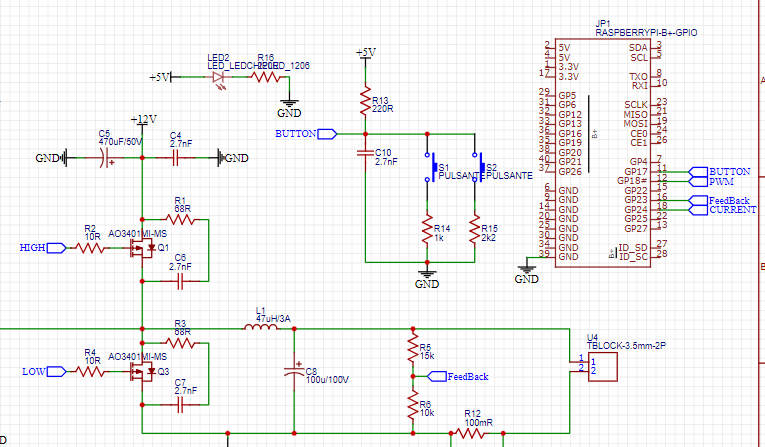

In the circuit diagram, we have reached the final stages of the design. At this point, we introduce the IR2104PBF, which plays a crucial role in processing signals within our system. These signals, provided by the IR2104PBF, are then fed into our Raspberry Pi, effectively enabling a PID (Proportional-Integral-Derivative) control mechanism.

To provide user interaction and control, we have incorporated pushbuttons into our system. These pushbuttons are programmatically configured in our code, allowing users to select predefined voltage levels and perform other specified functions.

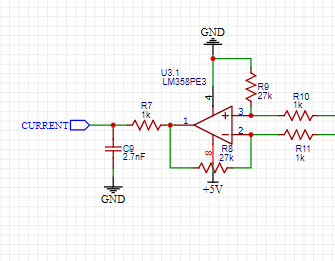

Furthermore, we have included a current measuring component in our circuit. This component utilizes a 100mohm resistor to sense the current passing through the system. The voltage generated across this resistor is then compared using an op-amp, and the resulting voltage is sent to the Raspberry Pi for further mathematical analysis. This current sensing functionality is crucial for monitoring and analyzing the performance of our circuits.

In order to facilitate testing and future expansion, we have provided the option to utilize additional pins on the Raspberry Pi. This allows us to control the power supply without interfering with the necessary pins for other functionalities. By ensuring flexibility in pin usage, we can continue working with the program and exploring new possibilities without constraints.

As we move forward with our project, we will proceed to test our circuits using the current sensor. This will provide valuable data and insights, allowing us to refine and improve the performance of our power supply.

By incorporating the IR2104PBF, pushbuttons, current sensing, and flexible pin usage, we have developed a comprehensive circuit design that showcases the potential of our electronic device. Through continuous development and iteration, we aim to create a robust and versatile power supply system.

In my upcoming blog post, I will be introducing another module that I believe is crucial for anyone learning electronics. This module holds significant importance throughout the learning process, and reflecting on my own journey, I wish I had access to this valuable resource from the beginning. I am excited to share my insights and experiences with you in the upcoming post.

Learning electronics can be an exhilarating yet challenging endeavor, requiring a solid foundation and continuous exploration. Throughout my own journey, I have encountered various modules and components that have played a pivotal role in my understanding of electronics.

Thank you for joining me on this journey, and I look forward to sharing this insightful blog post with you soon. Stay tuned for more updates and happy exploring!

Top Comments