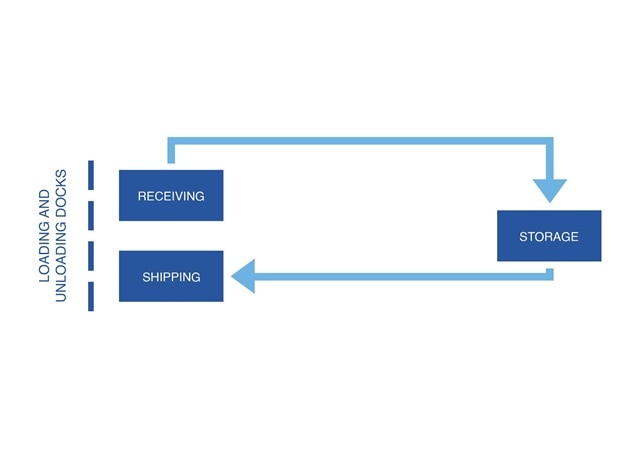

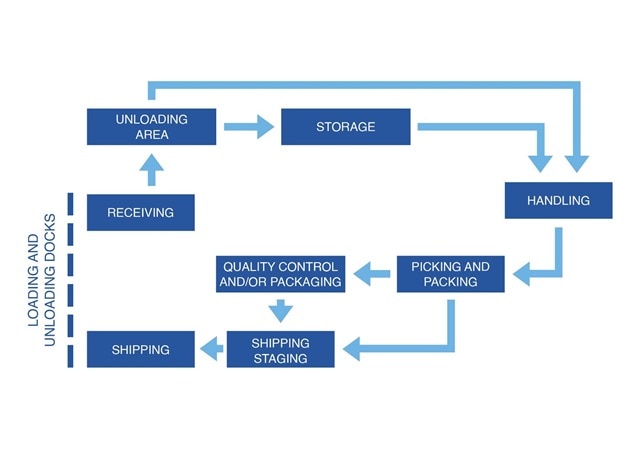

As I said in my entry you must identify the flow of things in the warehouse. So what is flow? And what Automation can we use? Hehm, two questions. Let's try to answer them. So the first thing is to define the flow. The two line drawings are from www.bluecart.com. The first is simple flow and it's not good for much not even drop shipping. The second flow is

As I said in my entry you must identify the flow of things in the warehouse. So what is flow? And what Automation can we use? Hehm, two questions. Let's try to answer them. So the first thing is to define the flow. The two line drawings are from www.bluecart.com. The first is simple flow and it's not good for much not even drop shipping. The second flow is

| Simple Flow | Normal Flow |

|

|

plausible. But it's not realistic either. Why there is no place in receiving for tagging?

So what does receiving do?

1. Where do they match the invoice with the purchase order, the trailer(s), or what's on the trailers? And the best is that they call it storage how about a better label and call it what it is the warehouse?

2. Let's get rid of something they call handling. Handling is done whenever you see the nice blue line.

3. Why is QC and packaging one thing? Nope. QC is done continuously, from Receiving to Shipping and in between as well.

I will highlight a problem that is coming common in Receiving Operations. Let's say you get a trailer with a broken pallet. What do you do? Sometimes you call QC and or take photos. All the time you must complete an exception report. Let's say you deal with mundane Nut and Bolts ie hardware, and the palette is broken. You must rebuild a new palette and toss the box of nuts on a counting scale and you find all the hardware but you are missing 10 parts. Complete the exception report, and put the broken box(s) into a secured location until the vendor has resolved the problem.

4. The Warehouse ie the Black Hole. Everything in the warehouse is in a location. Let me describe one of my warehouses. They are arranged in rows like in Home Depot. The next thing we will do is number the shelves. So if you use numbers for the rows then units are alphabetic, Shelves are numbers starting with the bottom shelf which is 0, and then you have two pallet spots per shelf A and B sounds good. PROBLEM if you already have 40 units and things are put where you group them. This will NOT work with this system. Things are loaded into the warehouse in FIAO (First In Any Out) then the next one in will take the first empty spot. Why because some things sell faster than others. So what do you do with Dead items? This depends on your business model.