Table of contents

Abstract

Building a DIY pick and place machine that is good for small hobbyist projects!

Project

Building Your Own DIY Pick-and-Place Machine

In this blog we’ll explore how to build a DIY pick-and-place machine using commonly available parts and an Nvidia Jetson for the brains.

The Concept

This build borrows concepts from DIY 3D printers. However, instead of a hot end for extrusion, we’ll attach a vacuum pump end for picking up and placing parts on a PCB. The project is designed to be modular, precise, and relatively low-cost compared to commercial pick-and-place machines.

The Build

-

Axes and Motion

- Z-Axis: The Z-axis will be driven by two motors, each paired with an M8 lead screw. This design ensures stability and precise vertical movement for picking and placing components.

- X and Y Axes: These axes will use single motors paired with GT2 tracks and pulleys. This setup is reliable and widely used in the 3D printing world for smooth, controlled motion.

-

Part Handling

The vacuum pump end replaces the traditional hot end. It will pick up components via suction and release them accurately onto the PCB. -

Motor Control

- Z-Axis Motors: Controlled by the TMC5272-EVAL-KIT, which offers smooth and precise movement.

- X and Y Axes: Driven by the Infineon BTN8982TA motor drivers, ensuring efficient and reliable operation.

-

Brains and Vision

The machine will be powered by an Nvidia Jetson Nano, connected to a Pi Camera. The Jetson’s AI capabilities will handle:- Object Recognition and Detection: Identifying components to pick.

- Alignment: Ensuring parts are placed accurately on the PCB.

Why Build This?

Building your own pick-and-place machine allows you to customize the machine to your needs, learn about robotics and AI, and save money compared to commercial options. Whether you’re a hobbyist or a professional looking for a DIY solution, this project will challenge your engineering skills and bring automation into your workshop.

Stay tuned, and happy making!

Project Genesis: Modifying the Green Mamba v2.0

Every great project starts with a solid foundation, and my DIY Pick and Place Machine is no exception. I began by repurposing the Green Mamba v2.0 DIY 3D Printer design as the structural blueprint for my machine. This versatile base provides an excellent starting point for creating a custom pick and place system.

Structural Components: 3D Printed Aluminum Extrusion Mounts

The frame came together through careful modification of the original Green Mamba design, with a focus on 3D printing mounts for 2020 aluminum extrusion. These precision-printed components allow for a robust and customizable frame that can be precisely adjusted to meet the specific requirements of a pick and place machine.

Axis Configuration

The machine's frame is built around three primary axes:

- Y-axis:

- 2 Guide Rails

- TX2 Pulley

- 1 Nema17 Motor

- X-axis:

- 2 Guide Rails

- TX2 Pulley

- 1 Nema17 Motor

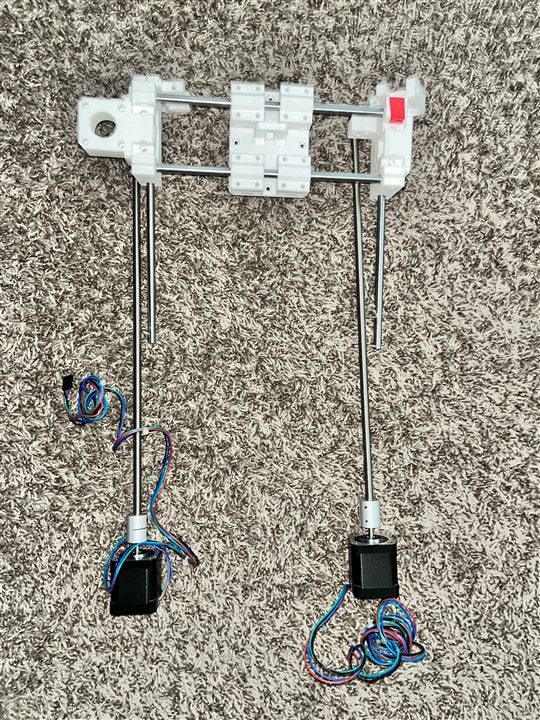

- Z-axis:

- 2 Guide Rails

- 2 Lead Screws

- 2 Nema17 Motors

Challenges and Modifications

No DIY project comes without its challenges, and this build is no exception. I encountered a critical issue with the lead screws and T-nuts that required some creative problem-solving. The 400mm lead screw worked perfectly with the T-nuts, but the 200mm lead screw I initially purchased didn't align as expected.

Adaptation Strategy

- Identified mismatched lead screw dimensions

- Explored alternative mounting solutions

- Developed custom modifications to ensure precise axis movement

Next Steps in the Build

Electronics Integration

The next phase of the project involves:

- Wiring up the electronic components

- Configuring motor connections

- Calibrating the axis movements

Motor Programming

A critical step in bringing the machine to life is programming the motors to understand and navigate the X-Y-Z planes. This involves:

- Developing precise movement algorithms

- Calibrating step sizes and movement accuracies

- Ensuring repeatable and consistent positioning

Image Recognition Development

Looking ahead, the ultimate goal is to implement image recognition capabilities:

- Designing algorithms for component identification

- Creating a machine vision system

- Developing pick and place coordination code

Hardware Setup

The current implementation uses a combination of different motor drivers to control our three axes:

- X/Y axes: TMC5272 stepper motor driver (via SPI)

- Z axis: L298N H-bridge motor driver

- Vacuum control: Infineon DC Motor Shield (to be implemented)

The wiring configuration is straightforward:

TMC5272 Connections: - SPI1_MISO -> Arduino MISO - SPI1_MOSI -> Arduino MOSI - SPI1_SCK -> Arduino SCK / SDA1 - SPI1_CSN -> Arduino D10 L298N Connections: - IN1 -> Arduino D6 - IN2 -> Arduino D7 - IN3 -> Arduino D8 - IN4 -> Arduino D9

Software Implementation

The code is structured to handle three main components: initialization, motor control, and serial command processing. Let's break down each part:

TMC5272 Configuration

The TMC5272 stepper driver is configured via SPI communication. The initialization process includes:

1. Setting up the internal reference voltage

2. Configuring the chopper parameters

3. Setting current limits for both holding and running states

4. Initializing position mode for precise movements

void initTMC5272() {

writeTMC5272(GCONF, 0x00000004); // Enable internal reference voltage

writeTMC5272(CHOPCONF, 0x000100C3); // Standard chopper config

writeTMC5272(IHOLD_IRUN, 0x00071703); // Set current values

writeTMC5272(RAMPMODE, 0); // Position mode

writeTMC5272(XACTUAL, 0); // Reset position

}

Movement Control

The system implements three movement functions:

- `moveX()` - Controls X-axis movement using the TMC5272

- `moveY()` - Similar to X-axis control (to be fully implemented)

- `moveZ()` - Controls Z-axis movement using the L298N

The X and Y axes use precise position control with the TMC5272, which handles acceleration and microstepping internally. The movement is calculated based on physical parameters:

const float mmPerStep = 0.02; // Lead screw pitch divided by steps

The Z-axis implementation uses a standard stepper sequence through the L298N driver:

void moveZ(int direction, int steps) {

const int stepDelay = 2; // Controls movement speed

// Implements standard 4-step sequence for bipolar stepper motor

// ...

}

Command Interface

The current implementation includes a simple serial command interface for testing:

- 'x' - Move X axis 10mm

- 'y' - Move Y axis 10mm

- 'u' - Move Z axis up 200 steps

- 'd' - Move Z axis down 200 steps

Next Steps

The next phase will involve implementing the vacuum control system using the Infineon DC Motor Shield. This will handle the pick-and-place head's vacuum pump for component handling. Additionally, I'll be working on expanding the movement system to include:

- Proper acceleration profiles

- Home position sensing

- Component position calibration

- Integration with a computer vision system

Holiday Update

Quick note: Due to upcoming holiday travels, progress will be minimal in the following week. But don't worry - development will resume at full speed once I'm back! Sometimes we all need a break to come back with fresh ideas and renewed energy.