The Pool Butler (airboat) has 2 plastic covered sandwich enclosures to protect the electronics from water.

Some of the interconnections are in between the boxes, and some wires are to devices outside the boxes.

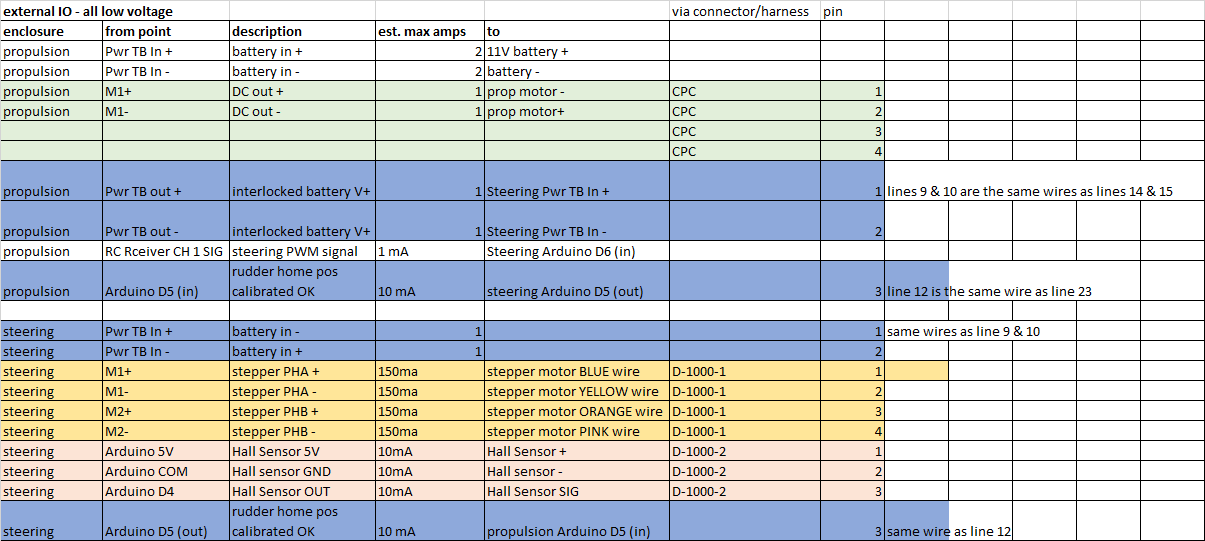

A wire schedule is used in buildings, control systems, etc to plan the wiring, cabling, signals in those cables, signal levels, etc...etc...etc. define all the wire and cable properties and materials needed.

Worried about having enough D-1000 pins for the Pool Butler, this first pass wire schedule was created.

The prop motor runs @ ~ 1 amp now, but could be upgraded in the future so decided to use the CPC connector for that ckt.

The build is ongoing and the wiring is getting messy. Time to make some of these harnesses and clean up the prototype Pool Butler.

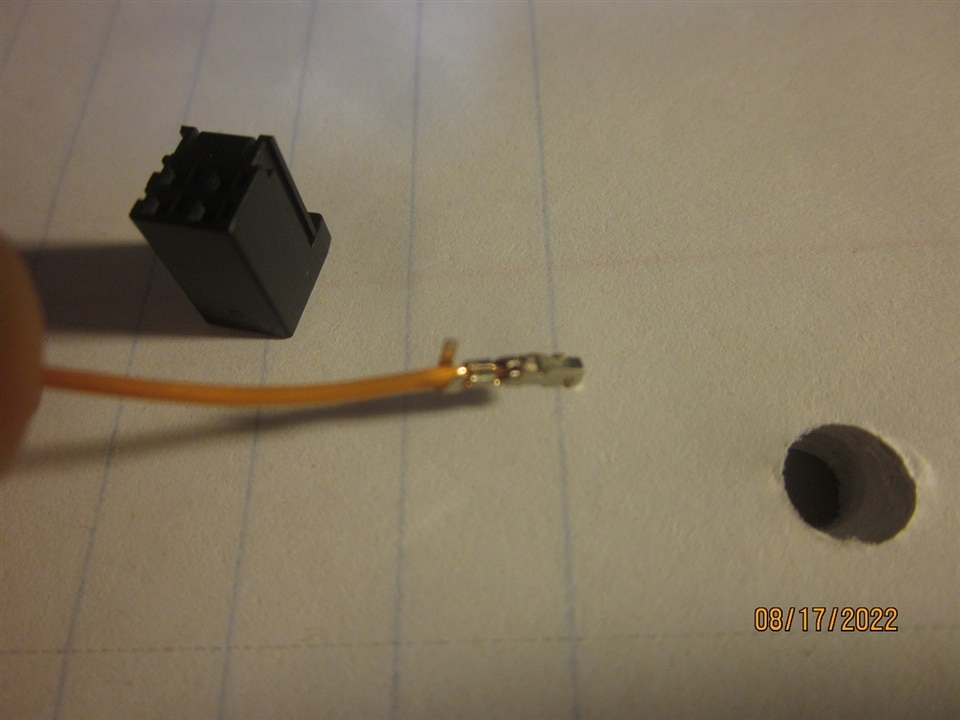

This is a pin crimper I got about 45 years ago, and used it to crimp the CPC and D-1000 pins fairly successfully.

If you have an old pin crimper on hand, follow the photos to see which groove was used for the different pins and how the pins were inserted into it.

Its not perfect, but got the job done.

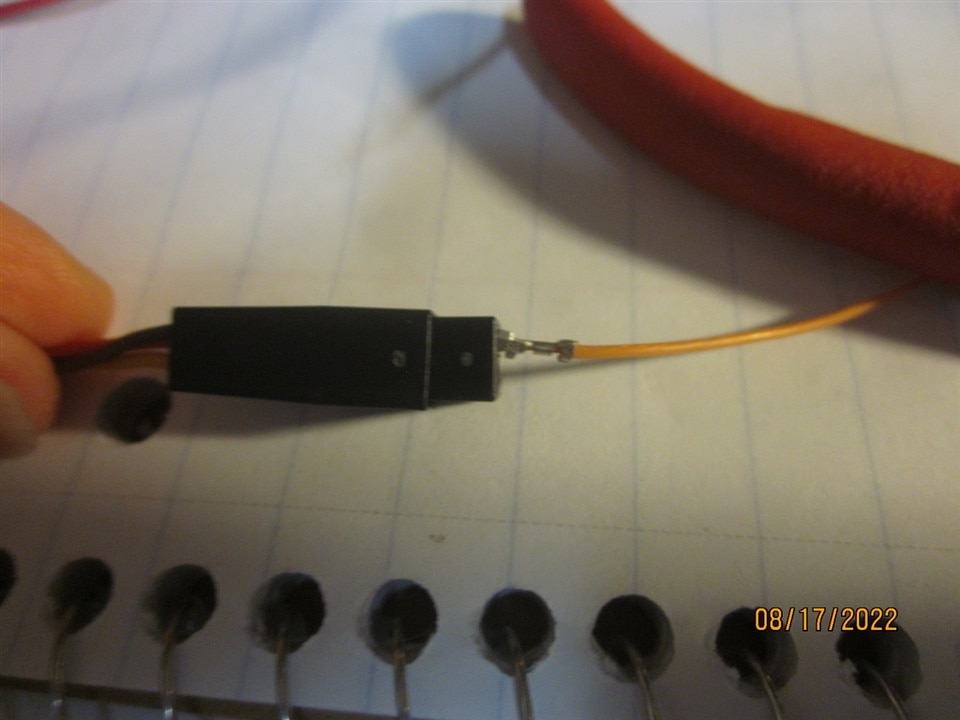

First photos of the CPC pins being crimped.

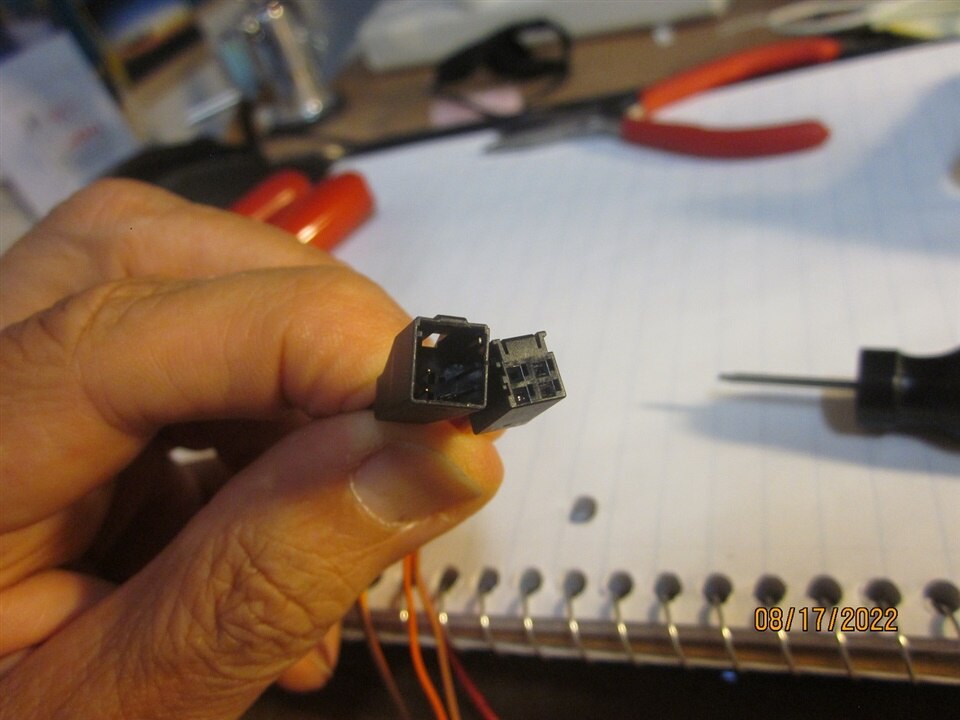

These photos are of crimping the D-1000 connectors

Next are the before and after harness photos

-

robogary

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

robogary

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children