Hey Guys,

I've decided to discuss my Retropie Handheld build, I would love feedback if it is constructive, now I had a 7" RPi touchscreen lying around, and decided to build it into a Retropie portable, now power requirements, had to be considered, now Powerboost chargers from adafruit wont cut it with the current feed needed for the RPi 3B+, so for the Power source, I'm using 4 LiPo cells, with a capacity of 4000mAh, wired as two packs, so i have two packs with an output voltage of 7.2v and then in parallel so I have a battery capacity of 8000mAh. I also cant use Adafruit stuff as there are no local stockists of the modules here in Adelaide.

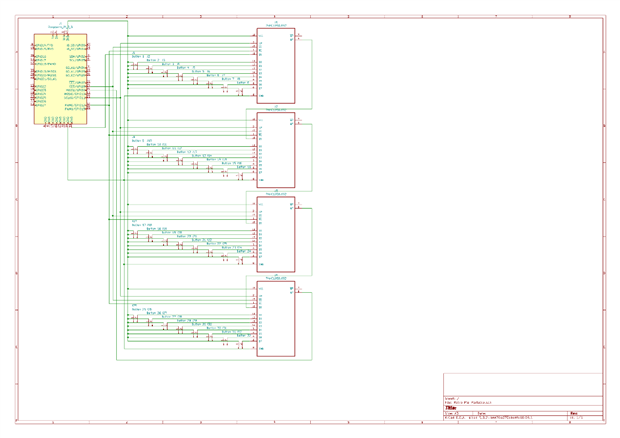

But with the charging circuit I've modified one I found for charging 4 cells that uses an ATMega328P, the changes I'm making is for charging 2 cells even though I'm using 4, I am assuming I can treat the two packs of two cells as two cells to the circuit. The other change is to add a means to switch from battery power to PSU when it is plugged in for charging. and load share between the pi and battery, the power from the PSU or battery then goes into a Buck Converter, (https://www.altronics.com.au/p/z6334-dc-dc-buck-module-3-40v-input/), so I can give the Pi and screen upto 2.5A at 5v. Also I'll be adding a means to the battery charging circuit if a low battery condition is detected, so that it can signal the RPi to shutdown if the voltage drops below a set threshold.

Now the reason for building my own charging interface is because here in Australia we don't have much in the way of standard modules, even ones with the power requirements of the RPi 3B+, plus I prefer a bigger handheld screen.

This is the reference I am using for building my own version of the charging circuit https://www.microfarad.de/li-charger/ this site is quite informative, and will help in customising this circuit for my requirements.

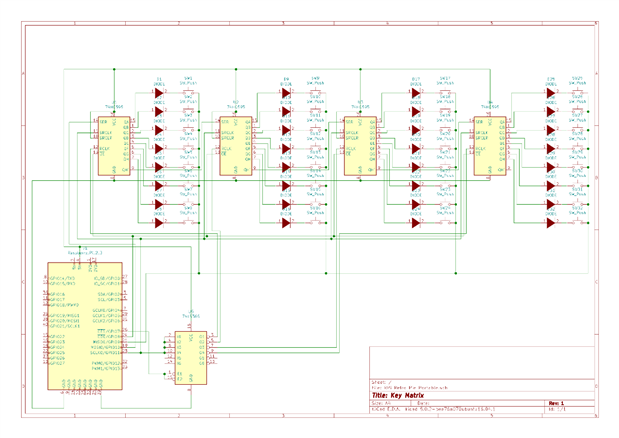

For the buttons I am going to use a basic key matrix, and take a page from the TBHS project where they did this, as its a good proven method of input.

The batteries I am using https://www.altronics.com.au/p/s4761-26650-lithium-ion-3.6V-4000mah-rechargeable-battery/

Controller I am using for charging https://www.altronics.com.au/p/z6222-sparkfun-dev-11113-pro-mini-328-5v-16mhz/

Plugpack for External power and Charging https://www.altronics.com.au/p/m8936b-powertran-12v-dc-2a-fixed-2.1mm-tip-appliance-plugpack/

I value constructive feedback of my project.

I also forgot to add, once I get the handheld working, I'm going to look at expanding it so I can plug 2600 cartridges directly into it, as I have been working on a 2600 cartridge interface. running into a few hurdles, so focusing on something a little easier

Regards

Paul

P.S. I'm umming and rring about actually recording this on video and doing a video of project.