Table of Contents

Introduction

This blog is about how I went about prototyping with RF devices called baluns. I wanted to have a reconfigurable method that would allow me to mess about with different topologies. I have not added a video for this project, because I'd like to be disqualified from the competition. I'm not suggesting I would win anything, but I have already won an RF Project14 competition not that long ago so I'd prefer the judges consider other projects. The method described here is very similar to that used in the past with wire-wrap modules. It is also very similar to how Ethernet transformers are assembled. I used both of those concepts here basically.

What are Baluns?

They are interesting devices that behave almost like conventional transformers. The word balun is short for balanced-unbalanced. Unlike a transformer, there is not necessarily electrical isolation from the primary to the secondary side, for DC current. However, for AC common-mode current, there is a high resistance between the primary and secondary side. This sounds like a very degraded conventional transformer, however, it has a huge benefit in that the balun can work to extremely high frequencies, and can often work across a wide band. The project here was tested up to 50 MHz (I didn't test further), and it is possible to create baluns that operate at GHz values and beyond.

Why Reconfigure?

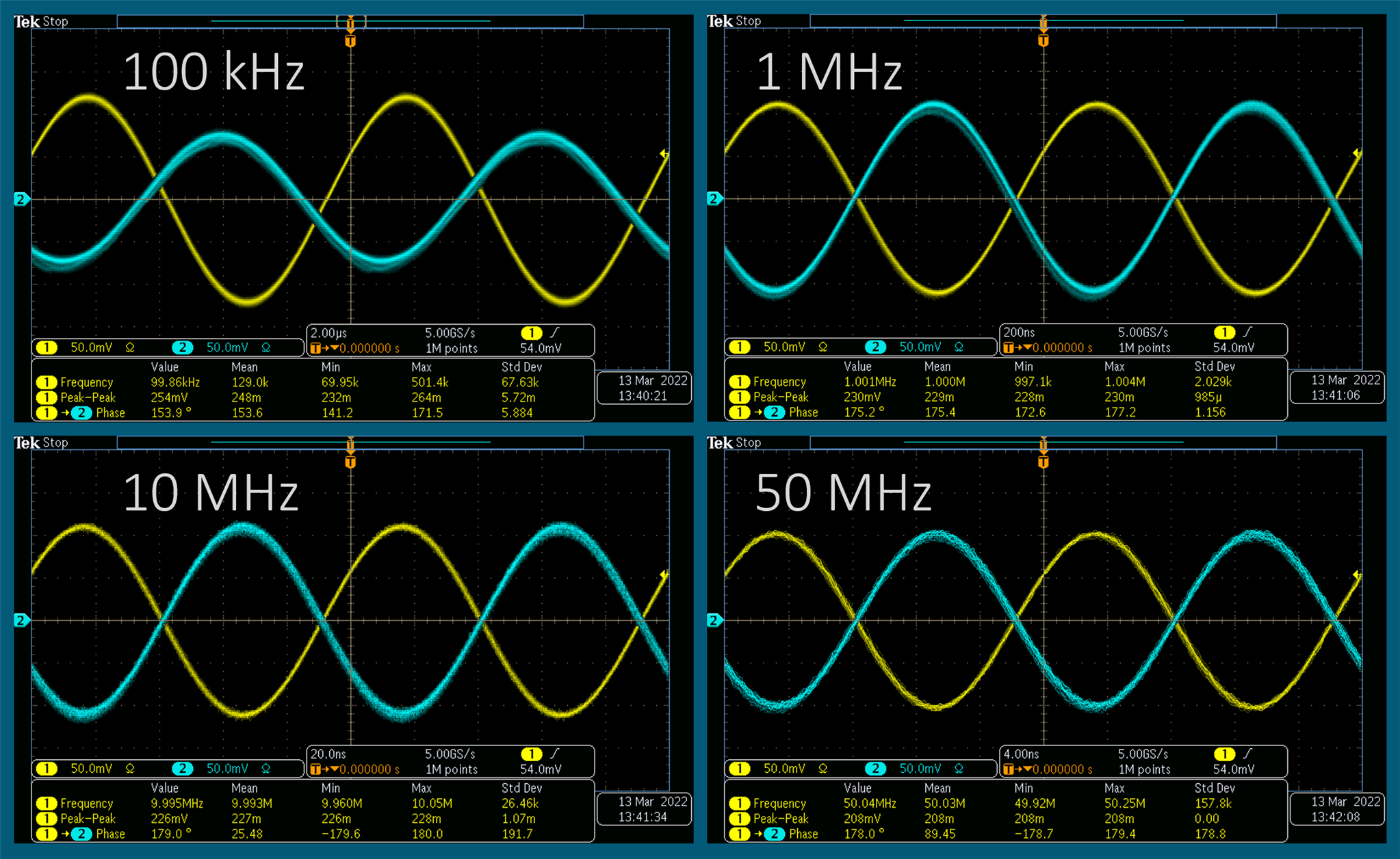

A balun on its own has uses, for instance, a good use-case is as its name implies, to interwork an unbalanced side (also known as ground referenced) to a balanced side, or vice-versa. However, if you combine more than one balun, you can do even more interesting stuff. As a result, it is highly desirable to be able to connect baluns in different configurations while experimenting. This blog post uses two baluns and some resistors to create a circuit that will split a signal into two, with one output inverted. A pluggable module method seemed attractive because there is also a desire to be able to swap out parts in order to tweak circuits. For instance, the baluns used in this project were found to not work very well at 100 kHz, and only worked well at 1 MHz and beyond. It would be nice to be able to swap out the baluns and try different ones to compare.

Parts Used

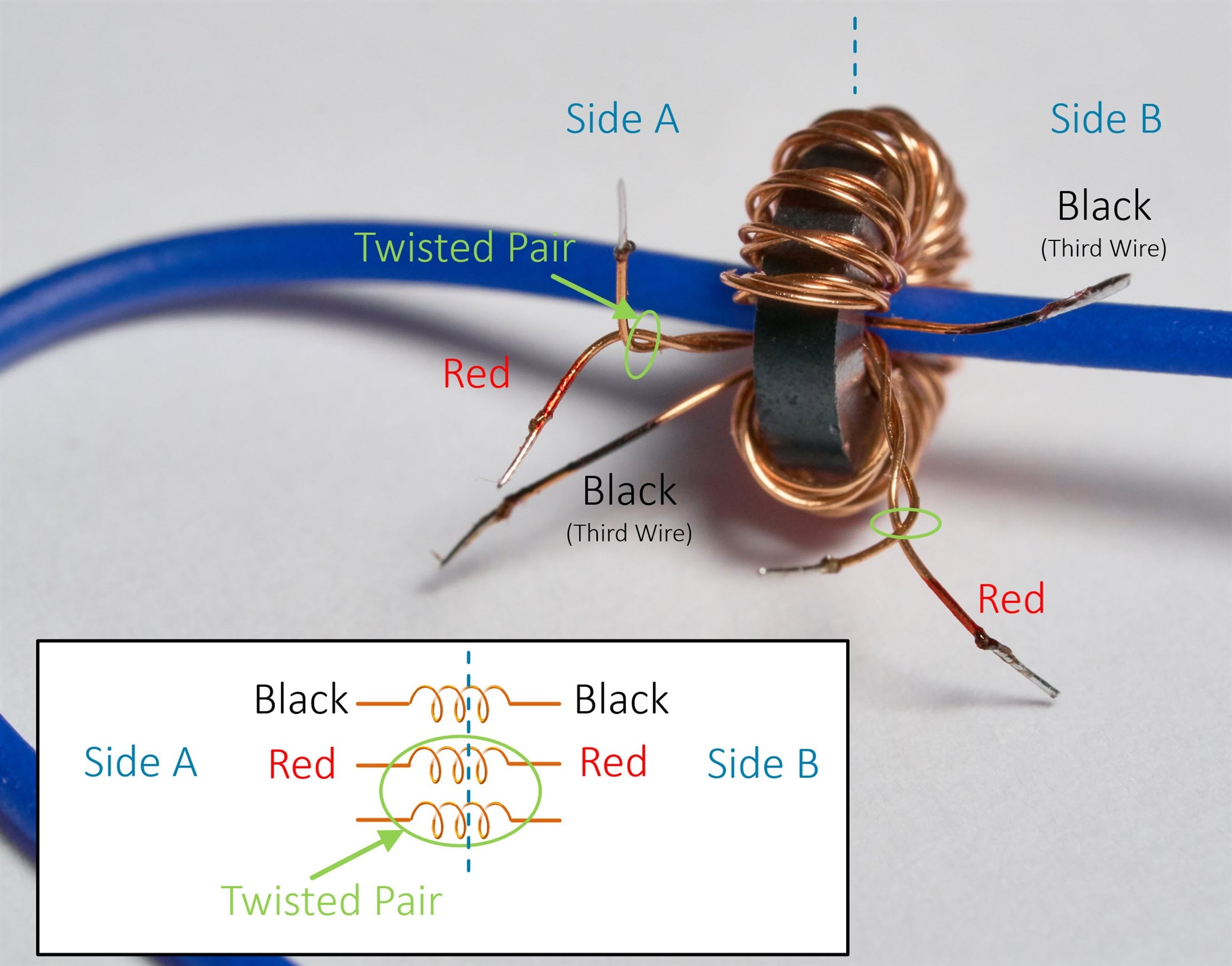

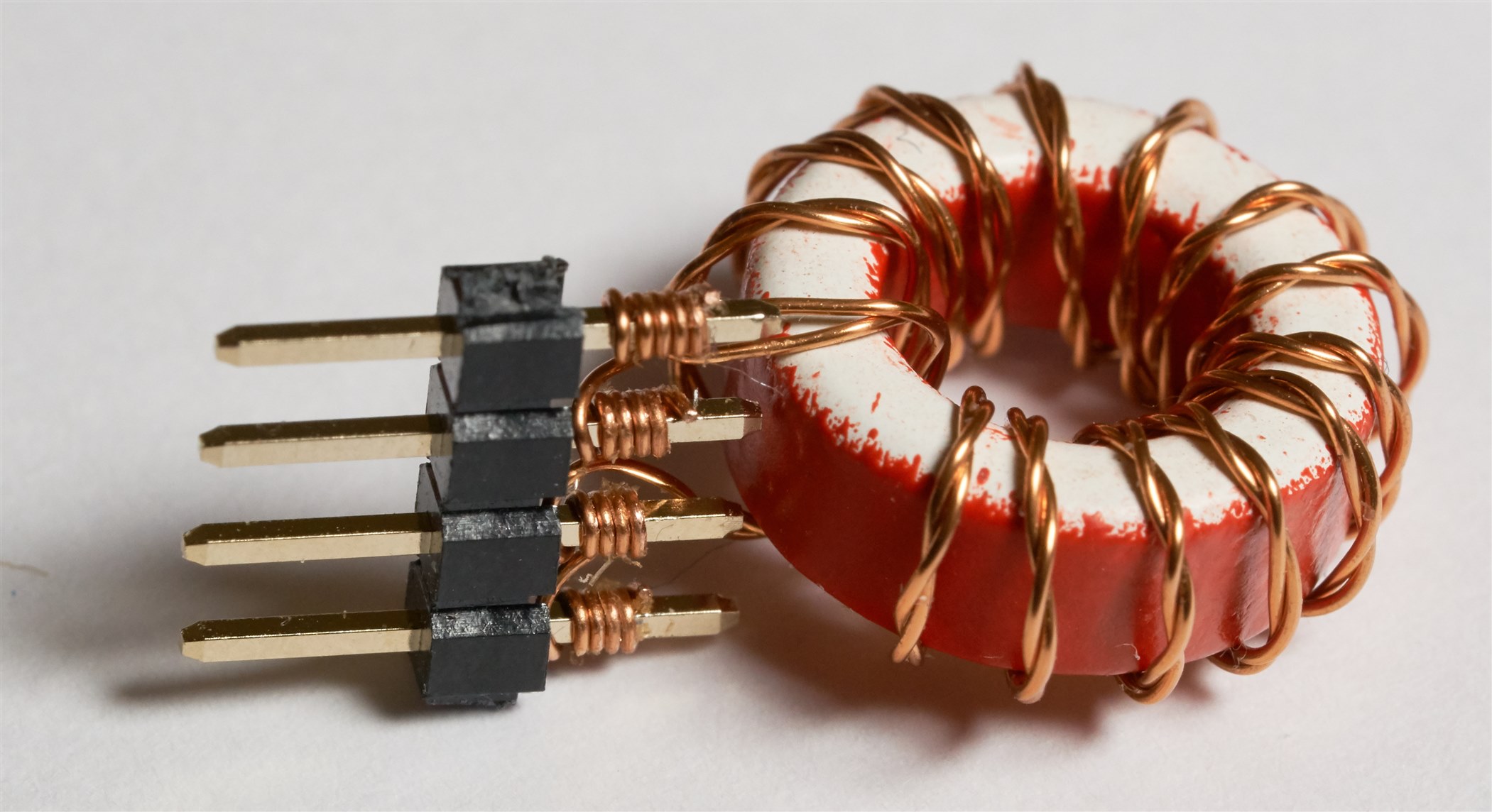

A balun was created by twisting two pieces of enameled copper wire and threading it through a toroid core multiple times. I created four such baluns, but for the fourth one, after I had twisted the wire pair, I then wrapped a third wire around it. It's beyond the scope of this blog post to discuss why such windings are required (because that's a rabbit hole), but if there's interest I'll write it up. Anyway, here is a photo of the fourth balun (these ferrite cores are small, so the blue solid-core wire in the photo is being used to prop it up; this support method also came in handy when I was heating the wire ends to remove the enamel). I used a multimeter set to continuity test mode to figure out which wire was which and then colored the end of the winding using a permanent marker pen.

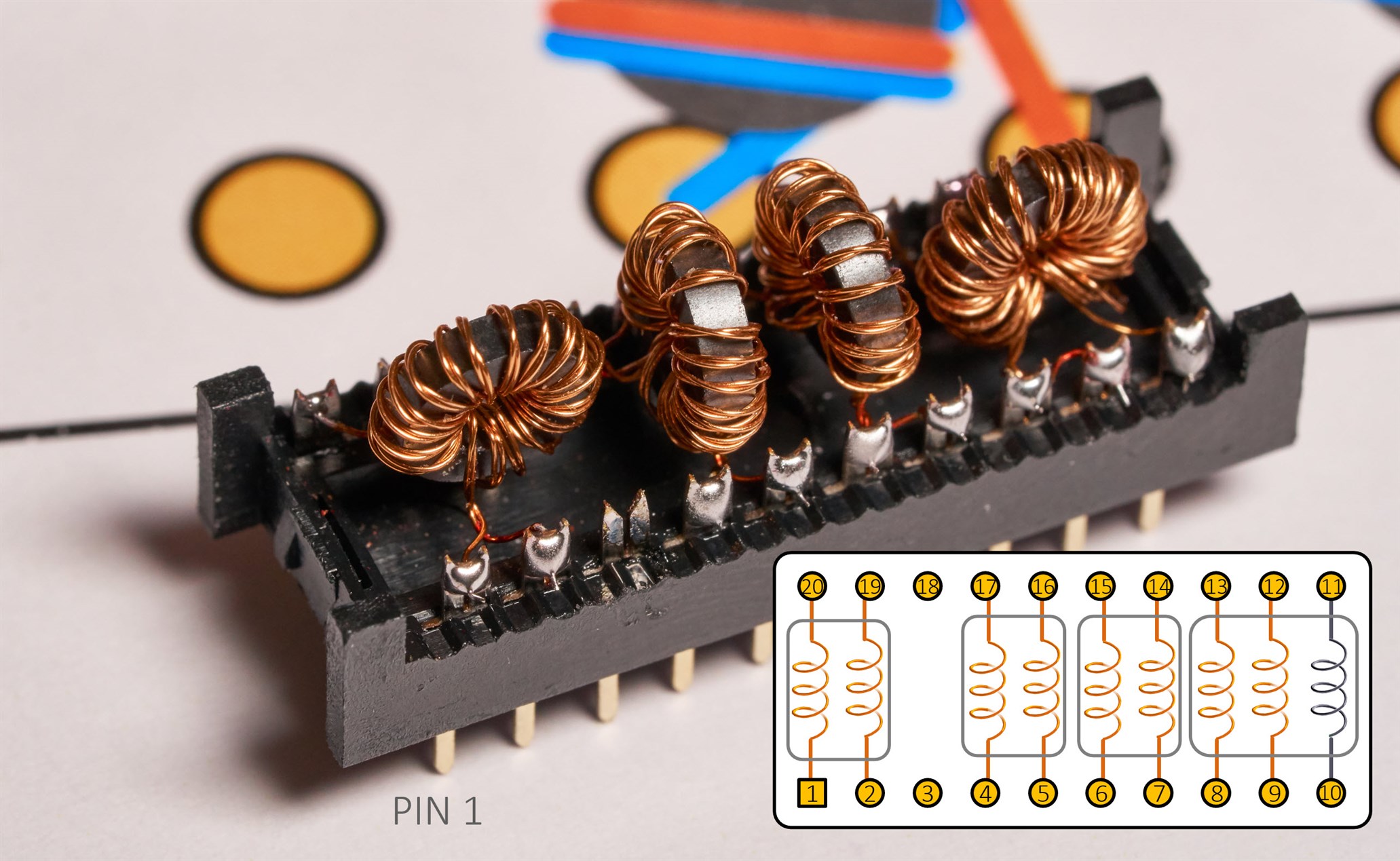

Next, I took an IDC DIP header used for ribbon cables and pulled off the plastic cover. I soldered the transformers onto it as shown here:

You can actually buy forked (and non-forked) DIP modules intended for soldering components, but they are more expensive, getting hard-to-find from distributors these days, and I didn't have any. The IDC DIP header worked fine. Anyway, my Balun Prototyping Module was complete!

Making a Circuit with the Multiple Balun Module

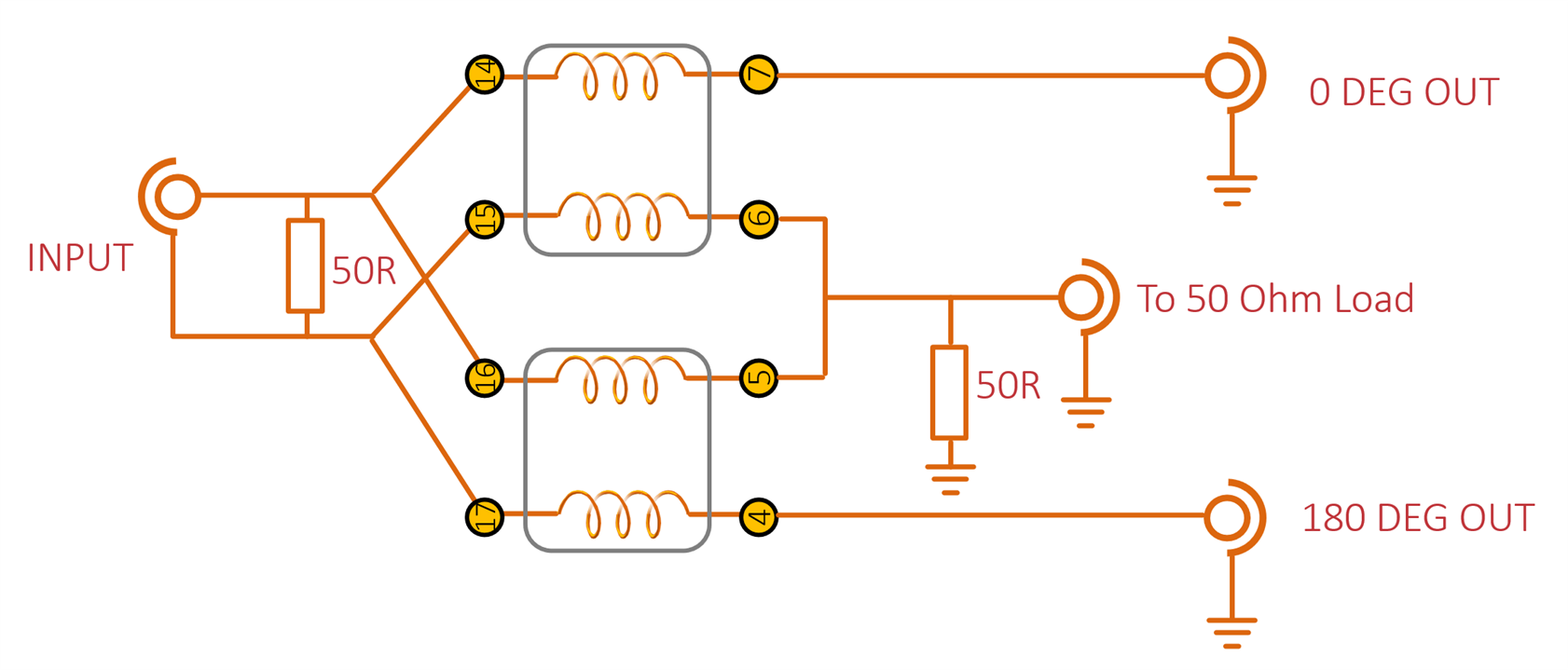

As a quick test, I assembled a circuit developed by C. L. Ruthroff in 1959 (in a paper simply called Some Broadband Transformers), known as a Hybrid:

For this circuit, I just used the two center baluns in the module. Of course, the module can be unplugged if I want to try to swap out the baluns with a new design.

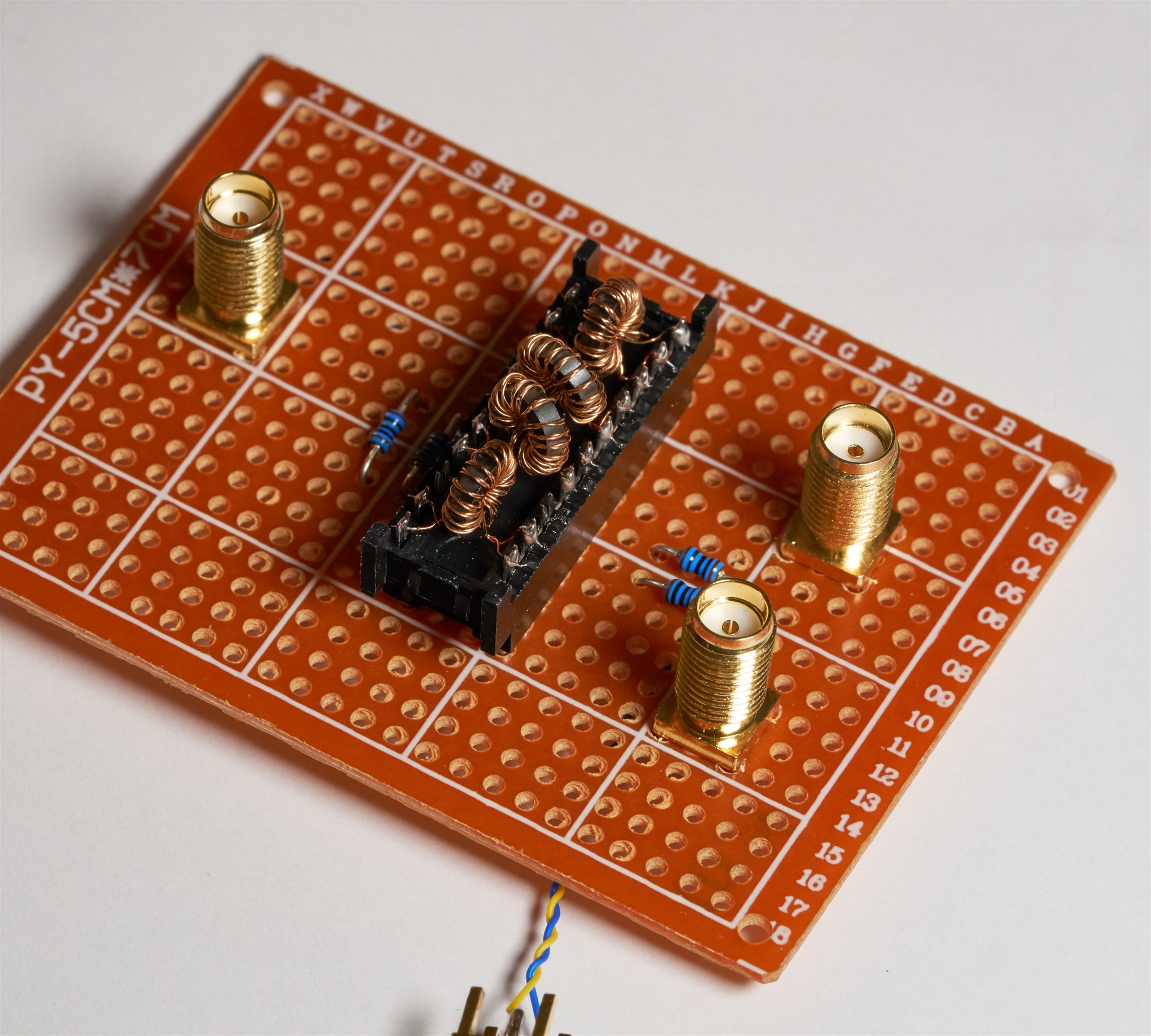

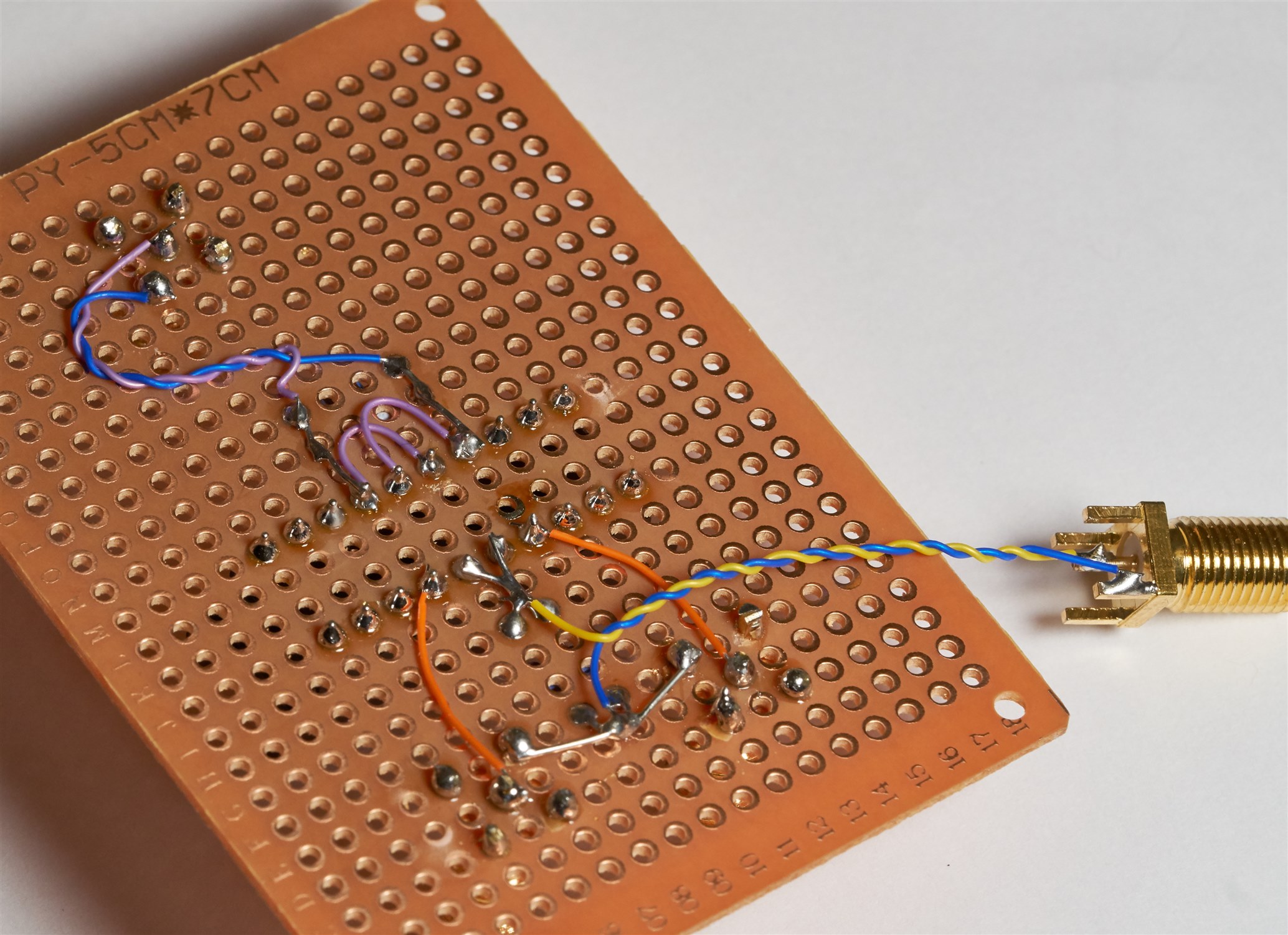

Here is the underside; one SMA connector is hanging off the board because I ran out of space on the small protoboard, I wanted to space the connectors out.

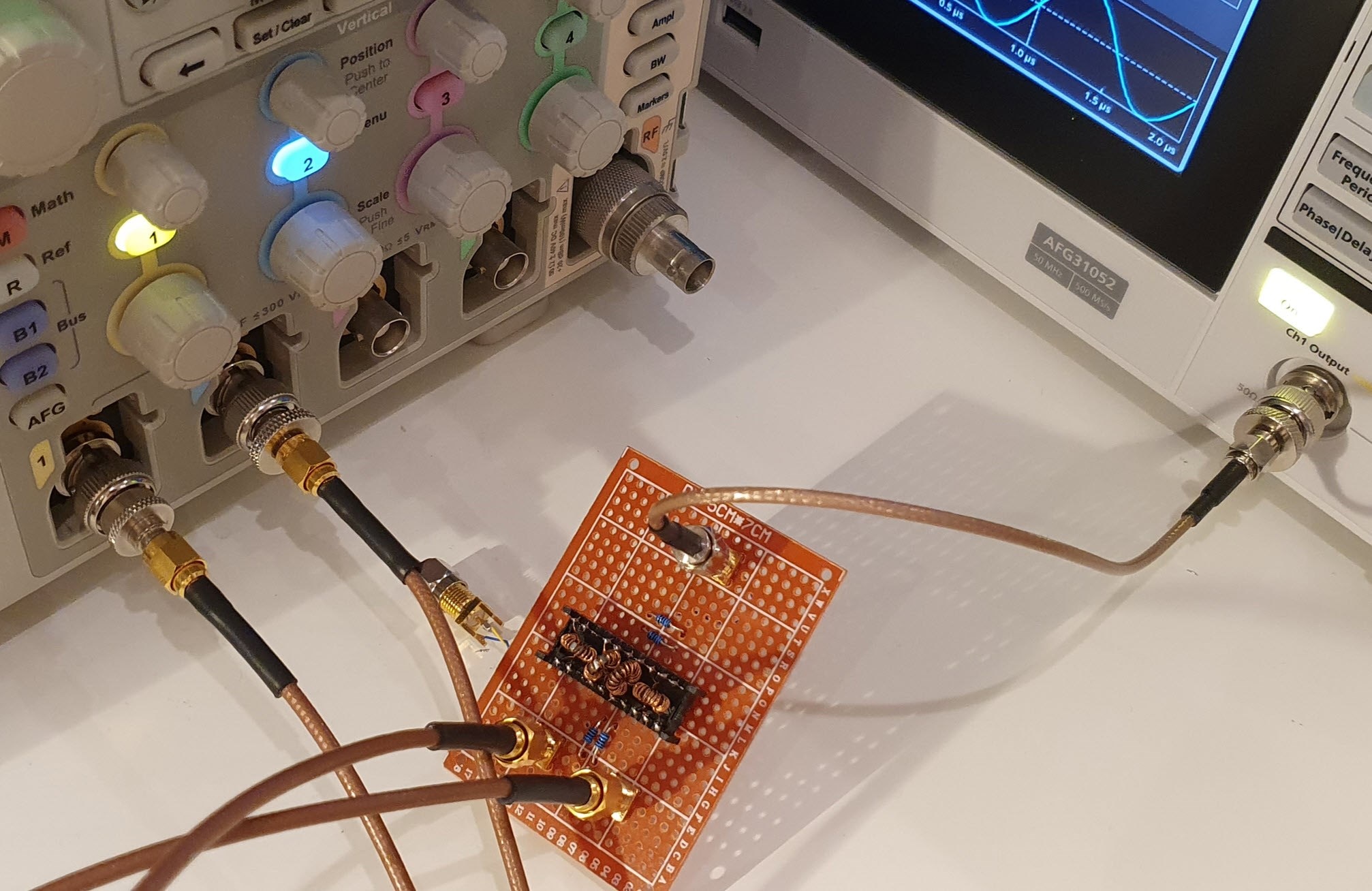

I hooked up the circuit to a signal generator and oscilloscope:

Here is the result; as can be seen, my implementation only works well from 1 MHz upward. I only tested to 50 MHz because that was the limit of the signal generator I was using (I could move to a different signal generator but this was just a first test).

Replicating the Project

If you wish to replicate this, the enameled wire was of 0.15 mm diameter, and two lengths of 30 cm were wound with about 10-12 twists per inch (i.e. one twist per 2-2.5mm), it's not critical, but try not to exceed that, and try to keep the wires touching throughout the twists, i.e. no gaps. The ferrite cores were Fair-Rite 5943000101 and I wound 18 turns, cut off the remainder, leaving 6 mm of wire, and then used a soldering iron and a blob of solder to burn off 2-3 mm of enamel off the ends. For the fourth ferrite, as mentioned, a third winding was added. That third wire was of the same length, wound around the twisted pair, but not with as much care, it just needs to ideally follow the same path. I didn't have 50-ohm through-hole resistors, so I used two 100 ohm resistors in parallel.

Other Ideas

I think wire-wrapping techniques could be a possibility for larger modules with wound components. For instance, here is an idea using a much larger core, and thicker wire – it was sanded on the ends prior to wire-wrapping with a WSU-30M wire-wrap tool . It's not a good idea to have tiny inductors on the ends : ) so the sanding needs to be fairly precise. Probably this method is better with coloured enamel, since then it is easier to see how much wire was sanded.

Summary

Pluggable modules can allow for more experimentation. I would not have liked to repeatedly solder/desolder tiny ferrite wound components, just to try out different topologies. Now, I can just re-wire the protoboard instead. The design could be improved with colored enameled wire (using this pack of 4 colors of enameled wire ), and also finding a way to secure the wound components mechanically (currently they are supported by the wire legs). To solve that, I'd like to perhaps investigate using UV-curing gel (it is used for securing nails apparently) at some point.

Thanks for reading!