I have spent some more time, working on the Arduino Hot Plate - What's for dinner?.

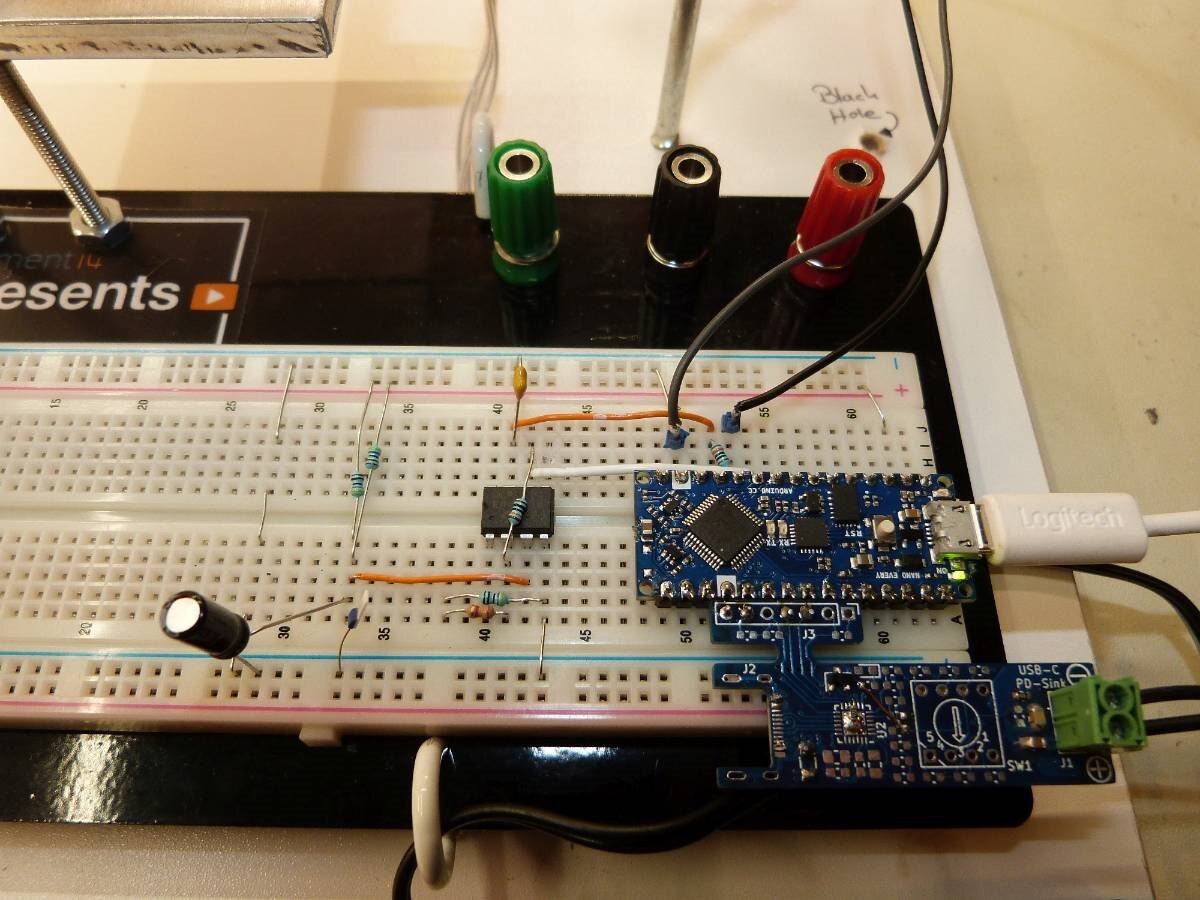

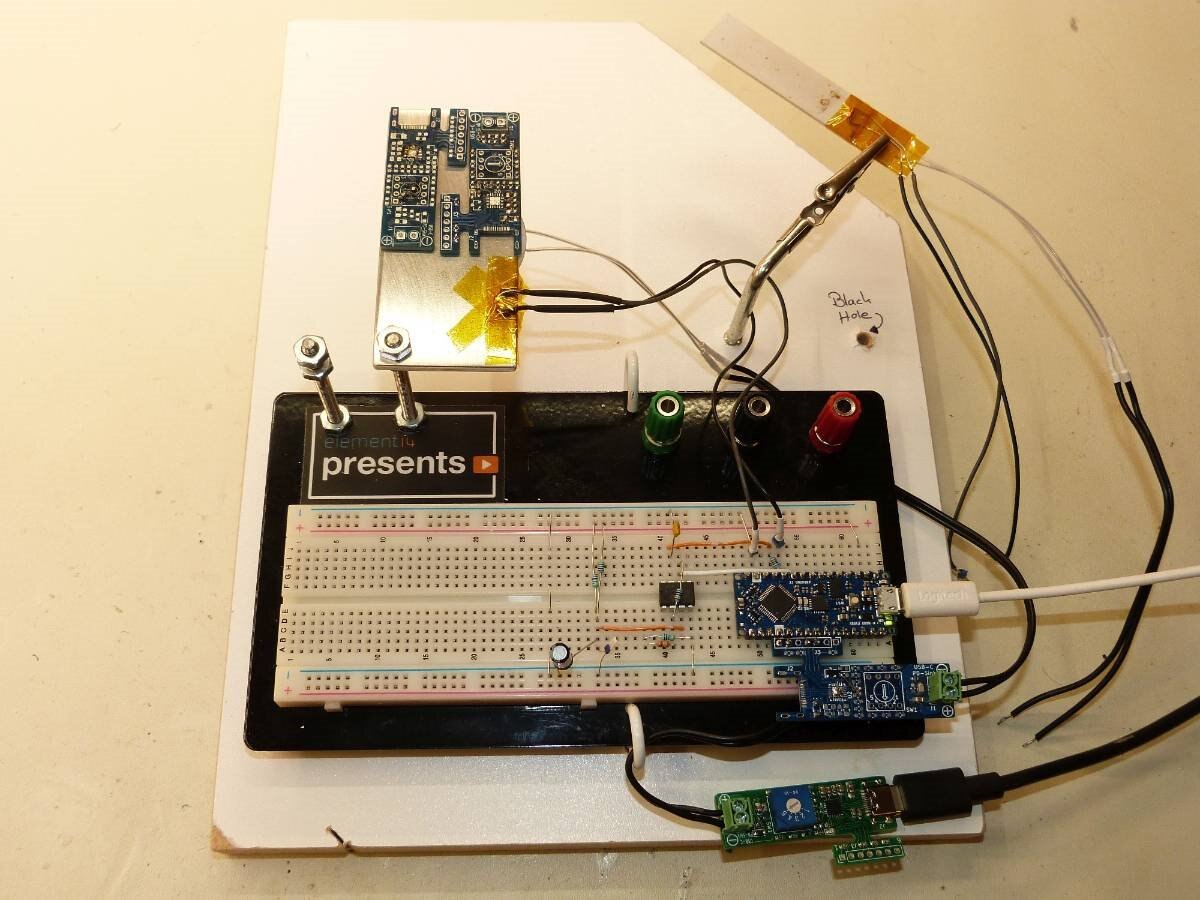

The breadboard was a mess with everything just plugged in. So I trimmed all the leads and made everything look nice and also more robust.

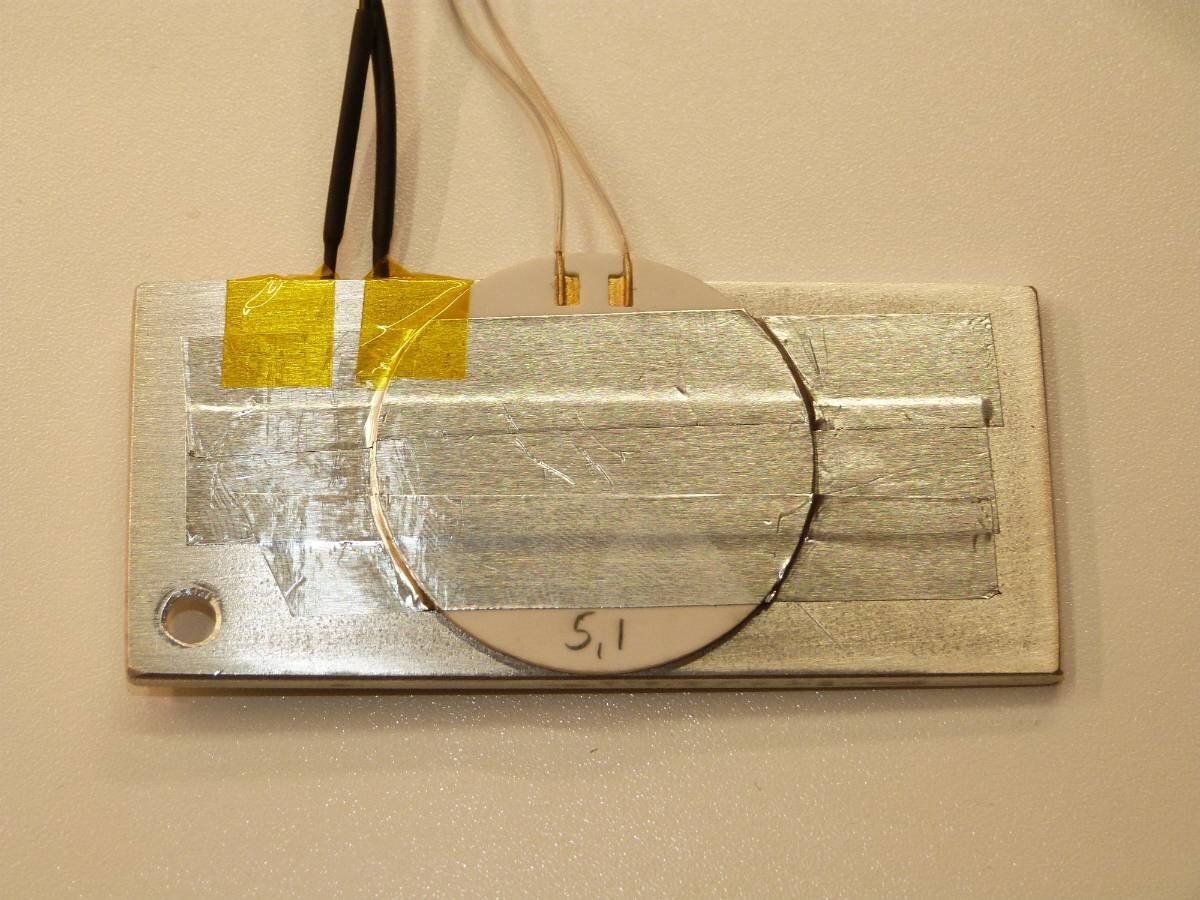

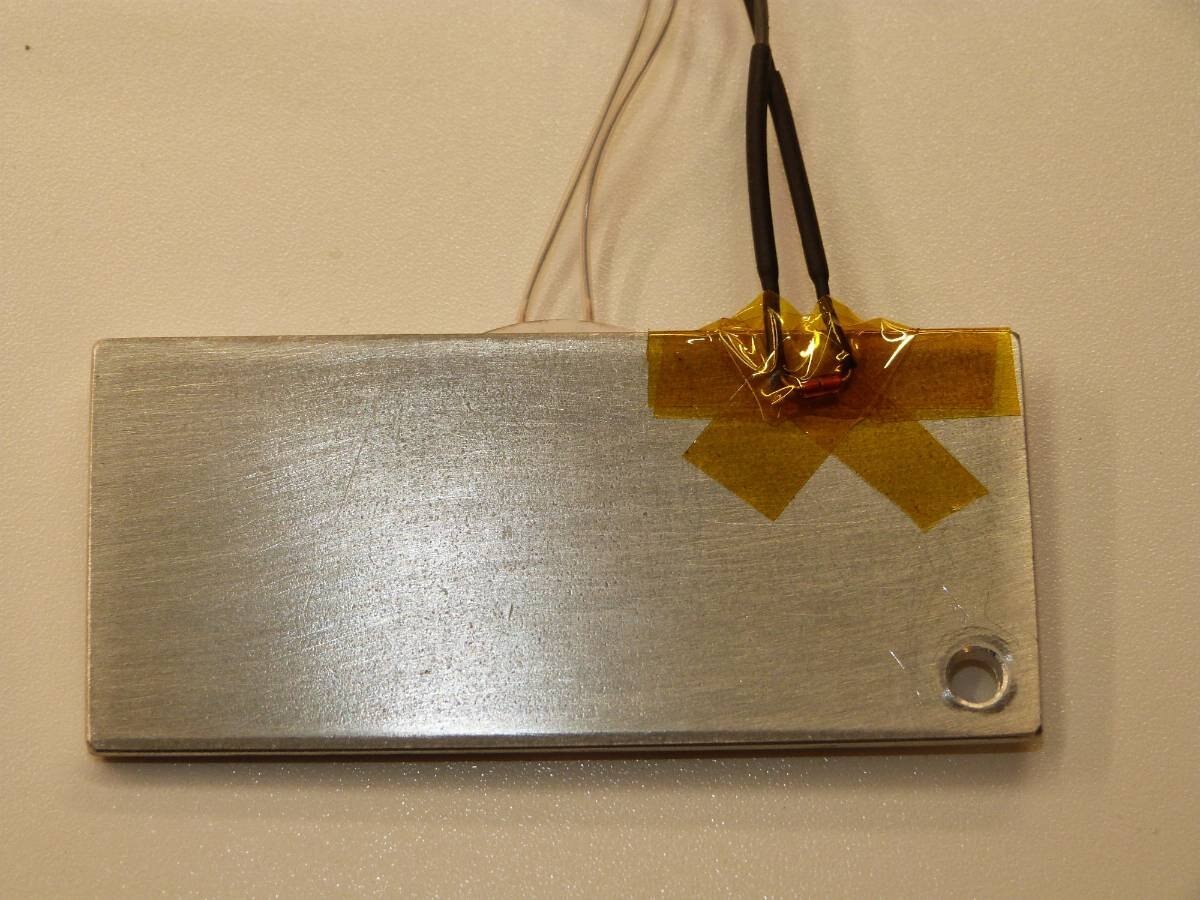

Also, with the big hotplate being too big for my power supply to heat up to soldering temperature, I am now using a smaller piece of aluminium (37mm x 82mm and half as thick) with a new round 5.1 Ohm heater element. It still lags behind the profile, but reaches a high enough temperature to melt the solder pieces and paste on my test-PCB. I still have to populate some functional boards and do a real soldering test. And the plate is big enough to hold 2 of my small PCBs, which is going to cut soldering time for multiple boards in half.

Here is the progress is pictures:

| {gallery} Arduino Hot Plate improvement pictures |

|---|

Tidy Breadboard: A clean version of my system on a breadboard |

New hot plate: Bottom side of the new smaller plate |

New hot plate: Top side of the new plate with the NTC sensor attached |

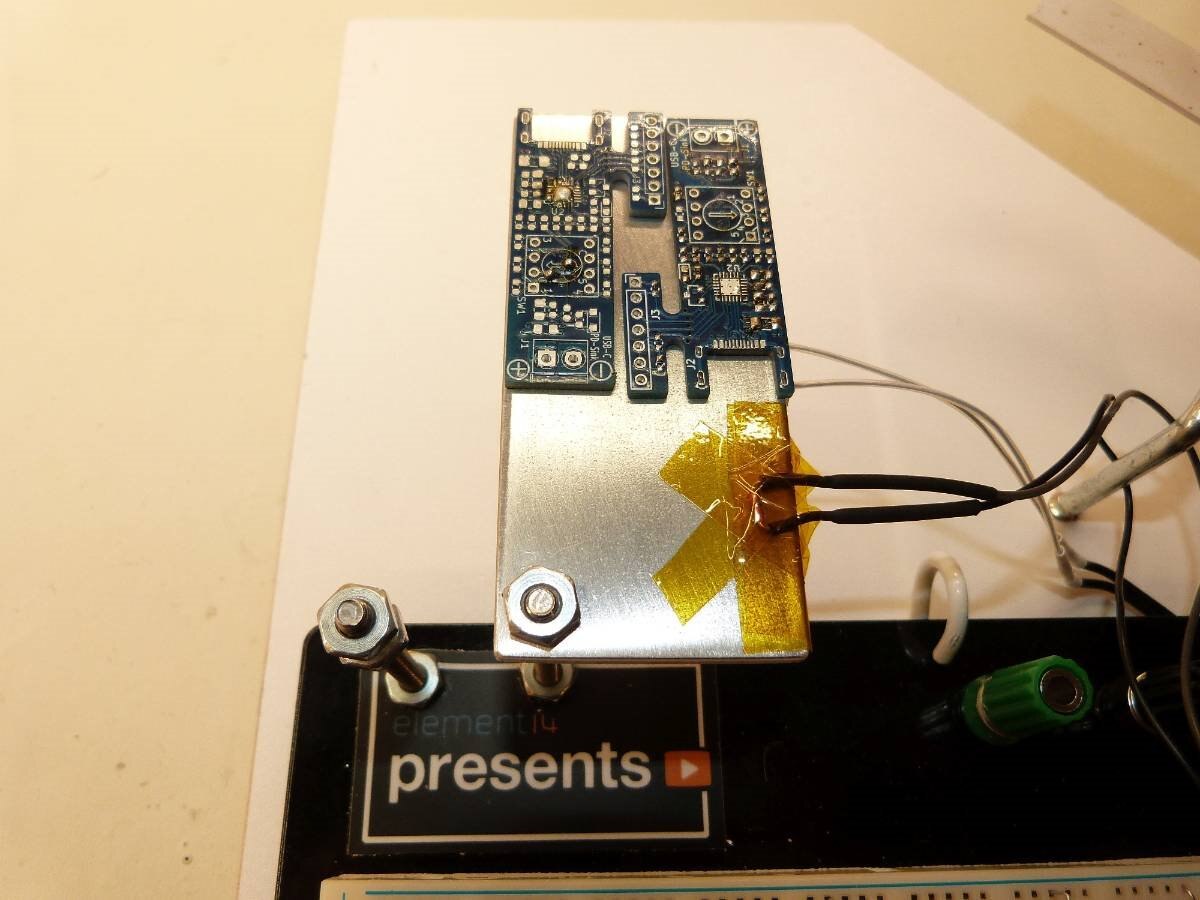

New plate mounted: 2 plates fit nicely |

View of the full system: Everything new |

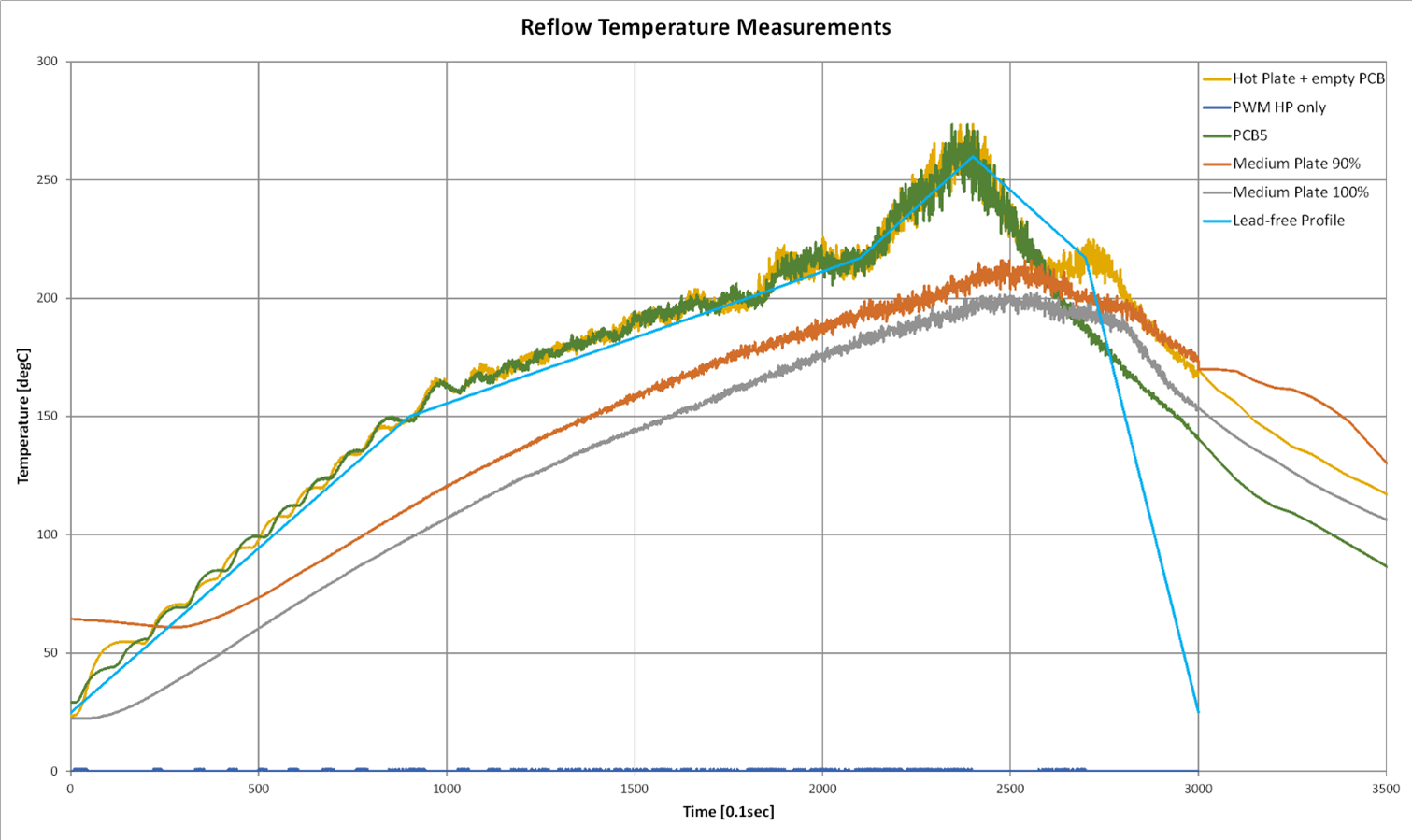

And some more test results. I added 2 graphs to the previous chart.

The brown one is a heating cycle with the new medium sized plate and a maximum duty cycle of 90%. The plate was pre-heated to 64degC from an earlier test and it is clearly visible, that the heating power is not quite enough to keep up with the profile. It got hot enough to melt the leaded and lead free solder pieces, which I put on the PCB. The grey graph has a maximum duty cycle of 100% but starts its cycle from ambient temperature. It reaches only a lower max temperature and did not melt the lead-free solder piece.

Those results also point to the fact that I need a bigger power supply.

The original to-do list is still not forgotten.

Enjoy.

Top Comments

-

DAB

-

Cancel

-

Vote Up

+3

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

wolfgangfriedrich

in reply to DAB

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

wolfgangfriedrich

in reply to DAB

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children