|

I bought a broken Dual turntable a few summers ago, as a summer holiday fun restoration project. And then didn't do anything with it. An ideal candidate for Spring Clean! .

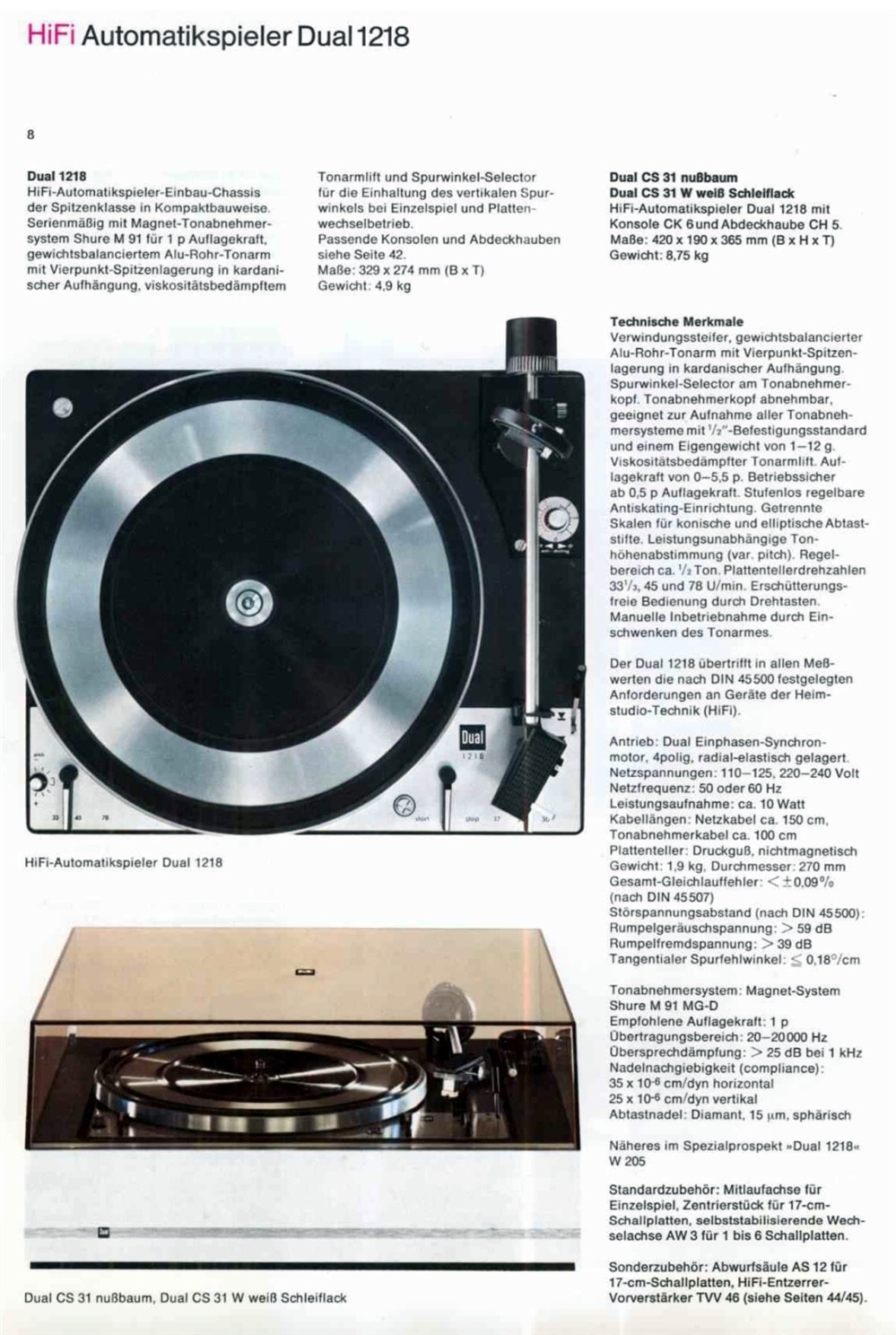

Facts: The DUAL 1218 is an early 1970s model.

It's an idler model - a rubber wheel transfers power from motor to turntable. Like all DUALs of the time, the automation is fully mechanic: wheels, cogs, levers, friction. |

What was wrong

In general: nothing worked. All levers were stuck, none of the automations worked. Motor didn't start. The platter didn't turn smoothly. And the stylus was broken.

Physically, there was damage to the acrylic lid. There was some damage to the arm. And the headshell plastic was brittle.

Most of the symptoms are to be expected. Most of the mechanic is frozen in place because lubricants got sticky or dried out. Some of the finer plastic components are brittle now, on all those tables - whether the table has been used, or is new old stock that never left the original box.

Restoration work: automation

Applying new grease and oil will not fix the table. The only way to get it back to functional, is to tear it down. Then remove all existing lubricants, and apply new one when putting it back together. Some parts, such as the power switch mechanism, are frozen together because of dried oil. Trying to force it will result in damage. The same with the two plastic levers for speed and disk size. If you try to force those levers before servicing the table, you'll break them. You'll be left with a doorstop.

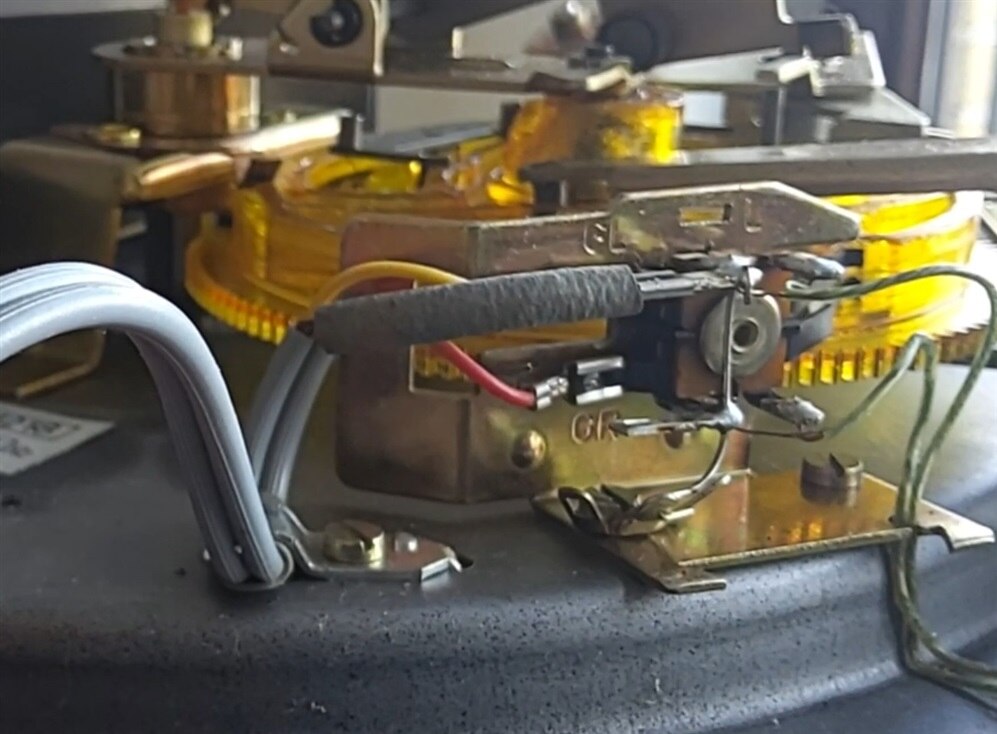

underside. The picture shows the table before teardown

The work to remove stuck components isn't complex, but you need to be very careful. Whenever you use force, you're doing something wrong. I removed motor, wiring, and the parts that blocked access to the lower part of the mechanism.

These pictures show different aspects before servicing:

Here, I have removed the components that block access to other parts that need to be serviced:

A first test to see if the mechanisms work after servicing - without the motor in place:

Service the motor

The motor was in good condition. But because I had removed it, it was an opportunity to service it and replace the oil.

... then placed it back:

Check power switch and suppression capacitor

In this model, the switch click suppression cap is usually good. I checked it anyway, to see if it was healthy.

At this time, I was able to do a full automation test:

And a first run of a single from start till end. This test was done with a temporary stylus:

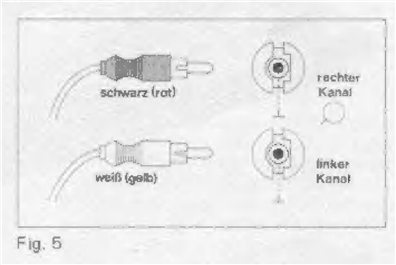

Conversion of the tonearm wiring from DIN to Phono

In Europe, this model was wired for DIN. That means that left ground, right ground and table chassis are connected together inside the table.

Somewhen it its lifecycle, a previous owner cut off the DIN plug and replaced it by phono (cinch) plugs. But they didn't split the 3 grounds as required by the phono wiring standard. I resolved that.

The phono plugs had bad contact. I replaced them.

|

|

|

|

Headshell and Stylus

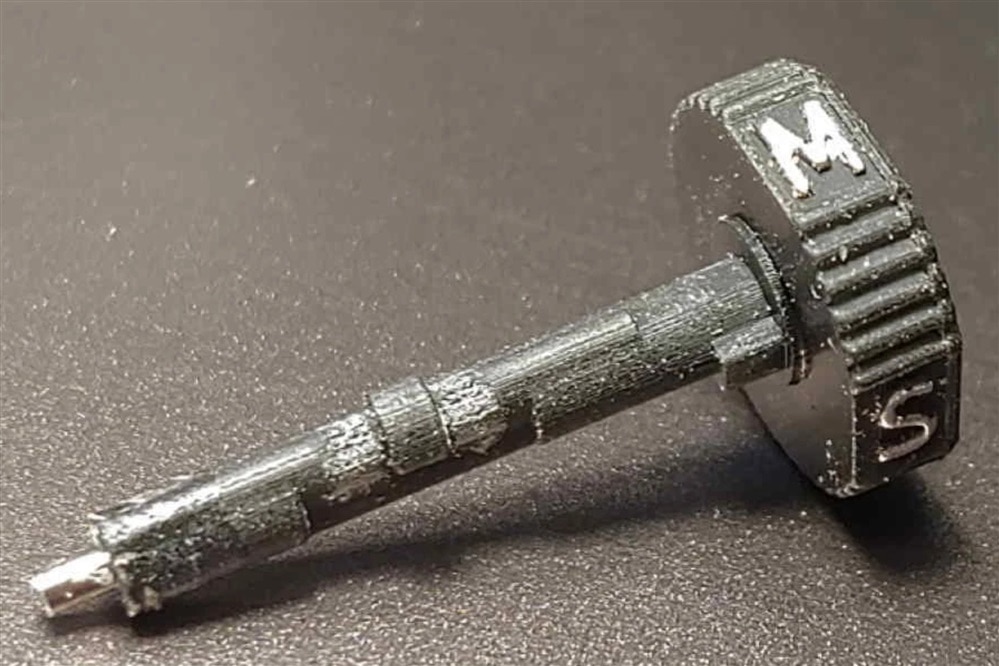

The 1218 is a stacker table. You can put 6 records on it. It 'll drop each record on the turntable and play it. Then the arm returns to the rest, a new record drops, and gets played. Etc. To compensate for the hight of 6 records, the headshell has an angle adjustment mechanism. That's broken on each table of this model now (if not, it will once you touch it).

I tried to fix this with glue. But then it just breaks somewhere else.

I found a 3D printed replacement on the internet. Not a good looker, but its functional:

image: vendor's photo of the replacement axle for tonearm angle adjustment

update 18-jun: the replacements arrived:

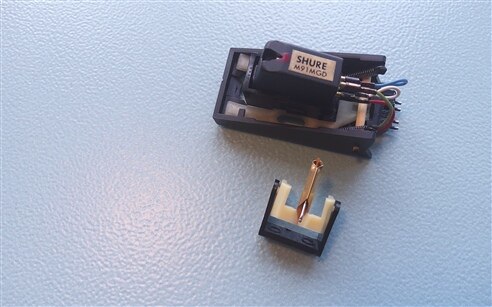

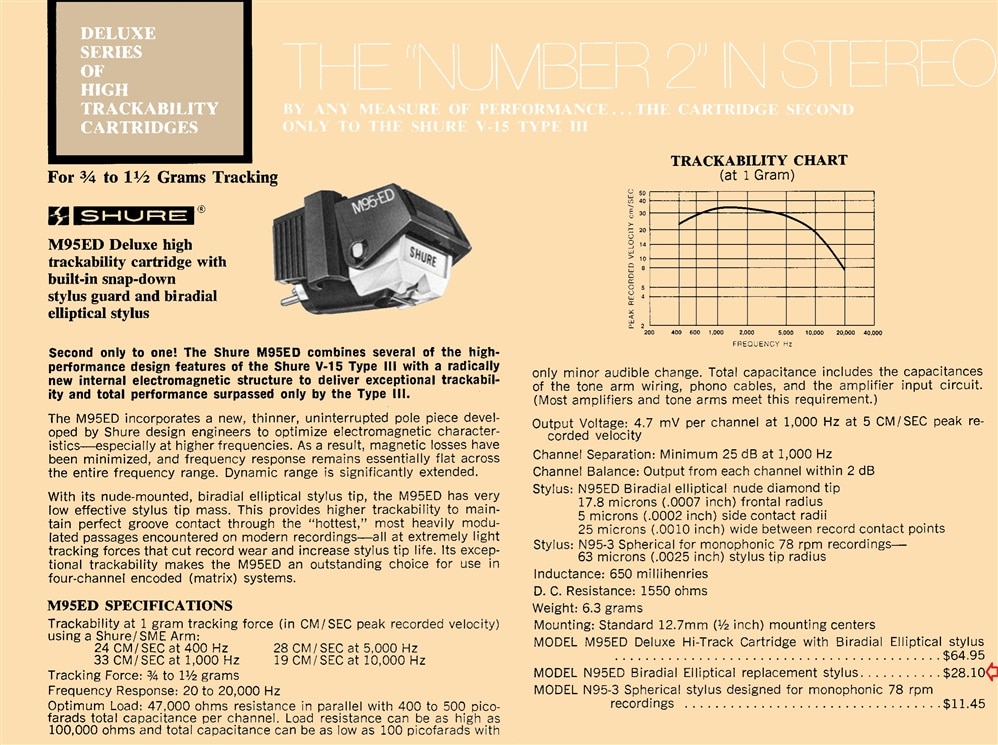

I fitted the stylus. It's an elliptical-cut aftermarket replacement for Shure's N95ED:

Housing Clean-up

There were several housing options for this table. In Europe, it typically came in the base that I have. It was dirty, with a part of the acrylic lid broken and glued back. I rejuvenated the veneer, and left the lid as is.

bonus: facts from DUAL's brochure:

image source: https://hifi-wiki.com/index.php/Dual_1218 - fair use, low resolution render. Click the link for the full resolution picture.

bonus: stacker in action

bonus: original documentation

Thank you for reading.

Top Comments