Introduction

Industry 4.0, or IIoT, leverages resources such as robotics, smart instruments, and programmable systems to boost production efficiency and optimize costs. This achievement requires the acquisition and integration of large amounts of data from devices and systems, which helps in making informed production decisions. Acquiring data from these devices and connecting them to a network becomes challenging due to vendor-specific protocols, legacy devices unable to communicate with the network, mismatched data models, and security issues. These challenges can be solved by establishing uniform interoperability and connectivity to achieve full and smooth integration between industrial automation devices and networks. However, implementing interoperability solutions for each device introduces challenges such as process disruption, budget constraints, lack of expertise, and security concerns.This article discusses the concept of interoperability, its challenges, and how HMS has mitigated them in water/wastewater and other industries through its Anybus line of products.

What is Interoperability?

Interoperability in an industrial automation environment is the capacity of different devices, including sensors, controllers, gateways, cloud platforms, and enterprise systems, to communicate, connect, and exchange information effectively across production processes regardless of their manufacturers or architectures. It enables hardware and software to support each other, allowing partners such as customers, suppliers, and various departments to share and use information quickly and accurately.

Interoperability in industrial automation operates across multiple layers. At the device level, sensors and actuators must communicate using compatible protocols such as PROFINET, EtherNet/IP, Modbus, and EtherCAT. Network interoperability ensures data can move across different network infrastructures, from fieldbus systems to wireless networks and cloud platforms.

Data interoperability represents another critical dimension, requiring standardized formats and semantic models that allow different systems to correctly understand and process shared information. This includes establishing common data models, metadata standards, and APIs that enable applications to process data from various sources with minimal customization.

What are the challenges of interoperability?

Interoperability in industrial automation faces several challenges that can affect the implementation and effectiveness of integrated systems. Some of those challenges are:

- Non-homogeneous or vendor proprietary protocols: Most manufacturing facilities use a combination of different protocols, each optimized for various use cases. Protocols such as PROFINET, EtherNet/IP, and CC-Link ensure real-time communication in industrial automation systems. However, these solutions often incorporate additional mechanisms to guarantee latency, and each lacks standardization, making interoperability a significant challenge.

- Legacy system integration: Many organizations rely on outdated, proprietary systems that struggle to communicate with contemporary industrial automation platforms. This creates barriers to modern automation integration, as these legacy systems cannot transmit real-time data. In addition, legacy systems often store information in siloed databases with incompatible formats, requiring special expertise and resources to extract, analyze, and consolidate data into shared storage.

- Vendor lock-in or dependency: Manufacturers often use systems supplied by different vendors. These systems generally run on proprietary protocols and present challenges when connecting devices across multiple facilities. This results in fragmented ecosystems where devices struggle to communicate effectively, leaving manufacturers locked into specific ecosystems.

- Data standardization issues: Industrial automation devices and systems often operate on different frequencies and protocols, leading to inconsistent, incomplete, or inaccurate data transfers between systems.

- Data security concerns: The lack of uniform security protocols and standardized frameworks makes industrial automation networks vulnerable to cyber threats. Outdated security frameworks also create data silos, which limit the effectiveness of AI-driven threat detection and analytics because data remains fragmented across systems.

- Implementation challenges: Implementing interoperable systems brings numerous challenges related to connectivity, data processing, scalability, and system reliability. For example, OPC UA offers many advantages, but implementing and configuring it requires deep knowledge of its architecture and capabilities, making adoption difficult.

- Cloud automation: With industries shifting toward cloud automation for faster results and real-time analysis, interoperability becomes more complex. Cloud components such as distributed environments, data mobility, and network resilience increase the difficulty of seamless integration.

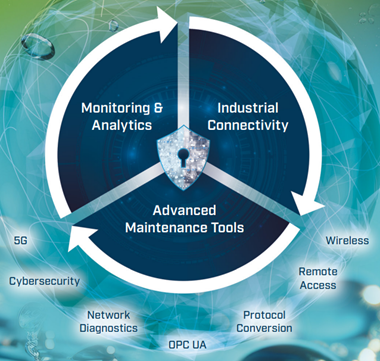

Figure 1: Interoperability challenges in Industry 4.0 (Source: HMS-Networks)

How has interoperability been addressed in the past?

- Early proprietary protocols and initial standardization (1970s - 1980s): Industrial communication began with HP-IB in 1975 (also known as the General Purpose Interface Bus, or GPIB), which established itself as a standard for industrial control. In 1979, Modicon developed the Modbus protocol, originally designed for their PLCs, which became a widely adopted de facto standard. These developments marked the beginning of industrial communication and fieldbus technology, though most solutions remained proprietary and lacked true interoperability across vendors.

- Standardization through IEC 61158: Specified by IEC 61158, Fieldbus encompasses protocols such as EtherNet/IP, Modbus, PROFINET, PROFIBUS, CAN bus, and CANopen. Each protocol has unique features, meeting the requirements of different industrial applications. While IEC 61158 aimed to unify the fragmented fieldbus landscape, it became more of an umbrella standard, legitimizing multiple competing technologies rather than creating one universal protocol.

- Rise of collaborative standards and OPC Classic (1990s): In 1996, Microsoft developed OPC, based on its Object Linking and Embedding (OLE) technology. This client-server model revolutionized data access by enabling historians, HMIs, and SCADA systems to uniformly retrieve data from PLCs across Windows-based platforms. However, this Windows dependency limited cross-vendor integration, particularly as Linux systems gained industrial adoption. While this era marked a shift from isolation to cooperation, it also exposed critical security vulnerabilities and portability constraints.

- Transition to platform-independent architectures (2000s): The launch of OPC UA in 2008 represented a major breakthrough. Built on TCP/IP, OPC UA introduced a service-oriented, secure framework that operated independently of operating systems and hardware platforms. Its object-oriented modeling enabled real-time data exchange, alarm management, and historical access from field devices to cloud platforms. Collaboration with standards bodies like IEC reduced vendor lock-in while preserving specialized functionality. However, high implementation costs for retrofitting legacy systems remained a significant barrier.

- Open initiatives and semantic enhancements (2010s - present): The rise of IIoT drove broader frameworks such as ExxonMobil’s Open Process Automation Standard (O-PAS), which aimed to enable seamless integration of multivendor components. Service-oriented architectures combined with semantic technologies have created intelligent, self-describing systems that coordinate complex IIoT operations with minimal manual configuration. The Unified Namespace (UNS) provides a centralized, publish/subscribe database that integrates data from all levels of the automation pyramid, enabling both automated and manual data gathering in a compatible format. These modern initiatives emphasize modularity, advanced analytics, and plug-and-play integration, though adoption still faces barriers of cost, complexity, and entrenched infrastructure.

Mitigating interoperability challenges using Anybus from HMS Networks

Anybus provides comprehensive industrial interoperability through embedded interfaces, gateways, and protocol converters that connect any industrial device to major networks, including PROFINET, PROFIBUS, EtherNet/IP, DeviceNet, Modbus, EtherCAT, and BACnet/IP, eliminating communication barriers and automation silos.

HMS Networks uses several integrated mechanisms to address connectivity challenges. Protocol bridging with Anybus X-gateways enables direct communication between PLCs from different vendors without middleware or code modifications, while maintaining performance and low latency. Legacy integration modernizes existing equipment by translating RS-232/485 or CAN protocols into Ethernet standards, allowing older components to connect to modern networks without hardware replacement. The CompactCom embedded modules enable OEMs to implement a single design across multiple networks using simple module swaps, accelerating deployment while minimizing development costs. Advanced security features, aligned with IEC 62443 standards, such as TPM chips, signed firmware, and secure boot help ensure cybersecurity while preserving flexibility.

Real-world applications

Wastewater solution - Valve integration over PROFIBUS

Durapipe, a supplier of water treatment systems, needed electrically actuated valves to communicate over PROFIBUS without redesigning their RS-232-based actuators. HMS Networks provided the Anybus Communicator AB7000, which connects non-networked devices to PROFIBUS by integrating serial RS-232/422/485 devices without modifications. The solution performed intelligent protocol conversion, presenting serial data to the Master PLCs as easily processed I/O data. It was housed in a separate IP65-protected enclosure, requiring no actuator redesign. The configuration proved simple for basic open/close valve commands, with potential for future diagnostic capabilities to support status monitoring and maintenance. It minimized downtime and successfully enabled PROFIBUS connectivity for water treatment applications.

Automated real-time monitoring of the assembly line

Comstar, an automotive component manufacturer, faced monitoring challenges with manual processes that prevented accurate defect diagnosis and delayed alarm acknowledgment. Red Lion by HMS Networks implemented the E3 I/O Module, DA30D, and Graphite HMI solutions seamlessly without affecting existing systems. The E3 I/O Module captured events through connected sensors, the DA30D logged status and transmitted data via radio modem to the control room SCADA, and the Graphite HMI provided local visualization. The solution delivered remote monitoring, reduced product defects, enabled real-time fault resolution, and provided a cost-effective, future-ready automation system, transforming manual monitoring into an efficient automated process.

Conclusion

Interoperability is essential for predictive maintenance, closed-loop optimization, and data-driven operations in industrial automation. The biggest challenge lies in networking devices with diverse protocols, legacy equipment, mismatched data models, and varying security requirements without disrupting production. Anybus from HMS establishes reliable, high-speed communication between any industrial device or system and all major networks, whether wired or wireless. This practical approach allows industries to modernize operations gradually, without major disruptions or excessive costs.

Featured Products

|

DA10D0C000000000 DA10D IIoT Protocol Conversion with RS232 and RS485 |

High Performance Protocol with Data Logger, Web Server and Virtual HMI |

|

X-Gateway, Anybus, EtherNet/IP Scanner to PROFIBUS Slave |

Anybus CompactCom 40, starter Kit - Pluggable Brick |

About the sponsor

HMS stands for Hardware Meets Software. By enabling industrial equipment (hardware) to communicate and share information with software and systems, our customers increase productivity and sustainability. HMS Networks was founded in 1988 in Halmstad, Sweden where you still find our head office. Today, millions of industrial devices all over the world use HMS products to get connected. Since April 2024, Red Lion Controls is a member of the HMS Group.

Top Comments