From battery cycling and renewable energy simulation to EV component testing, electronic design engineers are frequently required to test systems that consume and regenerate energy. Testing an EV battery pack, a regenerative braking system, or an energy storage module in microgrid demands controlled charge and discharge cycles without swapping equipment or wasting energy. Traditional power supplies often face limitations in these scenarios, as they either cannot support bidirectional energy flow or lack the efficiency required for such tasks. This is where programmable bidirectional DC power supplies come into the picture.

From battery cycling and renewable energy simulation to EV component testing, electronic design engineers are frequently required to test systems that consume and regenerate energy. Testing an EV battery pack, a regenerative braking system, or an energy storage module in microgrid demands controlled charge and discharge cycles without swapping equipment or wasting energy. Traditional power supplies often face limitations in these scenarios, as they either cannot support bidirectional energy flow or lack the efficiency required for such tasks. This is where programmable bidirectional DC power supplies come into the picture.

What is a programmable bidirectional DC power supply?

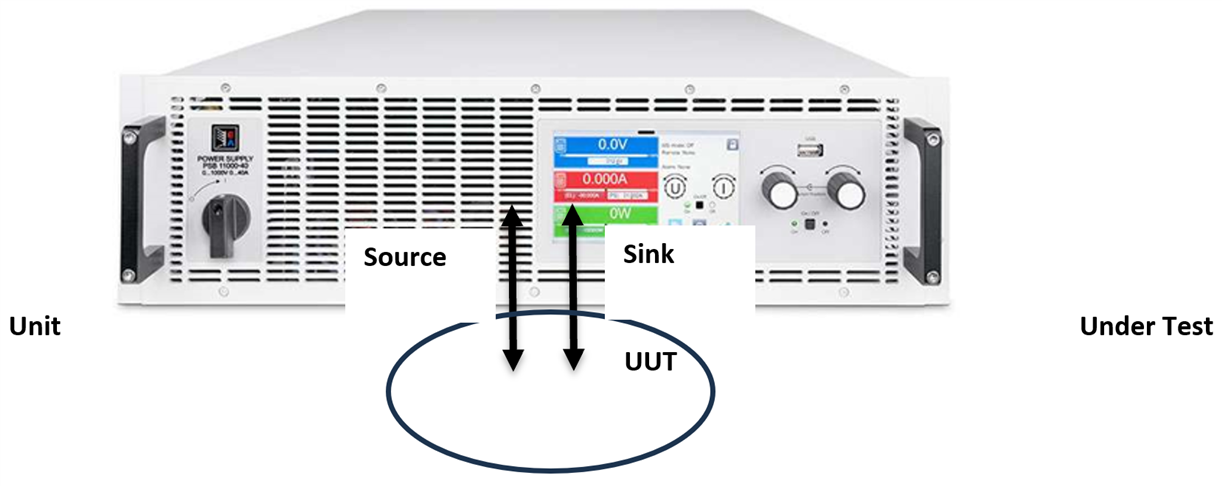

It is a test instrument that can source power like a traditional power supply and sink power like an electronic load. The EA-PSB series bidirectional power supply from Elektro-Automatik stands out as a leading solution; unlike traditional unidirectional power supplies that can only source power, these intelligent, two-quadrant systems are designed to source and sink energy, all within a single programmable platform. With up to 96% efficiency in regenerative operation, it supports advanced testing in battery simulation, EV charging, and renewable energy systems, offering engineers flexible, high-performance solutions for R&D and production.

Figure 1. EA-PSB 10500-10 2U, 0-500V, 0-10A, and 1.5kW (Image source)

Beyond standard DC power supplies

A standard DC power supply works in one direction—it supplies power to a device, such as 12V at 2A, to a circuit board. During discharge, you need a separate electronic load to absorb energy to test a power-generating device, such as a battery. This setup is bulky and requires coordination between two devices.

Figure 2. Single-chassis solution of a bidirectional power supply that can both source and sink power (Image source)

On the other hand, a bidirectional power supply works both ways. It can seamlessly switch between sourcing and sinking power within one unit. For example, it can charge a battery at 4.2V and discharge it at 500mA without changing equipment. Unlike standard supplies with fixed limits, its auto-ranging feature delivers full power across a wide voltage and current range. It’s also regenerative, converting absorbed energy back to AC and returning it to the local or facility grid with over 96% efficiency.

| Feature | Standard DC Power Supply | Programmable Bidirectional DC Power Supply |

|---|---|---|

| Operation | Operates in Quadrant I only (sources power; positive voltage and current). | Operates in Quadrants I & II (sources and sinks power; positive voltage, positive/negative current). |

| Programmability | Adjustable voltage/current via USB/GPIB; output is static. | Highly programmable via FPGA; supports dynamic control and fast transient response (<10 ms). |

| Key Features | Basic programmability; requires separate electronic load for sinking. | Autoranging, regenerative (up to 96% efficiency), waveform generation, Ethernet/CAN/USB, analog control. |

| Energy Handling | Cannot sink power; energy-generating DUTs need separate loads, dissipating energy as heat. | Sinks and recovers energy; returns it to the grid, reducing thermal load and improving efficiency. |

| Efficiency | High for sourcing (80–90%), but no energy recovery. | Up to 96% with energy regeneration. |

| Applications | General electronics testing, Circuit prototyping, Low complexity ATE |

EV battery cycling & powertrain testing, PV/wind inverter testing, Aerospace |

Table 1. Comparison table of standard vs. programmable bidirectional DC power supplies

How it works: The technology inside

The EA-PSB 10000 2U and 3U series are two-quadrant programmable bidirectional power supplies, capable of operating as both DC sources and electronic loads, with seamless energy recovery back into the grid during sink mode. This dual functionality significantly reduces the need for separate power supplies and loads in test setups. The key technologies that make this possible are:

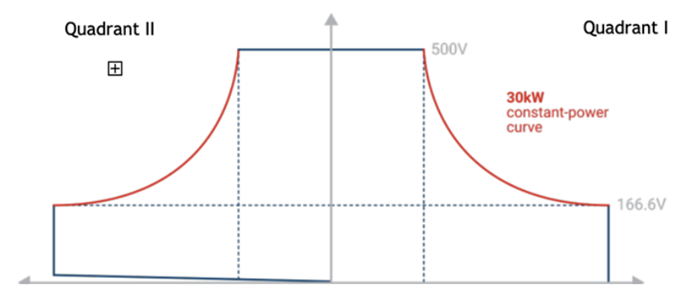

- Autoranging output stage: The EA-PSB 10000 2U and 3U series use a power-regulated auto-ranging design that delivers full power across various voltage and current combinations. For example, the EA-PSB 10200-50 2U 3kW model can supply 200V @ 15A and 60V @ 50A. This flexible output eliminates the need for multiple fixed-range power supplies, simplifies test setups, and reduces equipment overhead.

Figure 3. Constant power curve of a bidirectional power supply in quadrants I and II (image source)

- Bidirectional energy flow and regeneration: These power supplies operate in both source and sink modes, allowing seamless energy flow in both directions. When sourcing, they deliver precise DC power to the DUT; when sinking, they absorb power and return up to 96% of it to the grid. This regenerative capability reduces energy waste and heat, improving system efficiency and lowering cooling requirements compared to conventional setups.

- Integrated function generator and simulation capabilities: EA-PSB supplies include a built-in arbitrary waveform generator that simulates real-world power conditions using sine, triangle, trapezoid, or user-defined waveforms. This feature enables realistic testing of batteries, fuel cells, MPPT controllers, and solar inverters without needing external signal generators. The generator works in both sourcing and sinking modes, supporting accurate simulation of dynamic behaviours in power components.

Figure 4. Integrated function generator enabling advanced waveform simulations for power testing (image source)

- Advanced digital control and monitoring: Equipped with high-resolution 16-bit ADCs and DACs, the PSB series offers sub-millisecond response times and excellent voltage and current regulation. A digital PID controller ensures fast and stable output, while selectable control speeds (fast, normal, slow) allow users to tune the system for different test conditions. This makes the platform highly responsive and reliable for sensitive or time-critical power testing.

- Flexible connectivity and parallel scaling: The PSB 10000 series supports various communication interfaces, including USB, Ethernet, CAN, RS-232, Modbus, Profinet, and EtherCAT. It also allows parallel operation of up to 64 units with shared control via Master-Slave and Share-Bus functionality.

Figure 5. EA Elektro-Automatik CAN, rear panel I/O interface (image source)

- Electrical ranges: The 2U models deliver up to 3kW with voltages ranging from 0 to 1500V and currents up to 120A, while the 3U models support up to 15kW, reaching 2000V and 510A. Both units achieve up to 96% energy efficiency, ensuring high-performance output with minimal loss. These ranges make them suitable for everything from low-voltage battery testing to high-voltage grid simulation.

Real-life applications

The versatility of a programmable bidirectional DC power supply makes it a critical asset across several engineering sectors. Some real-world application domains where they enable not just testing but smarter, more energy-conscious product development are:

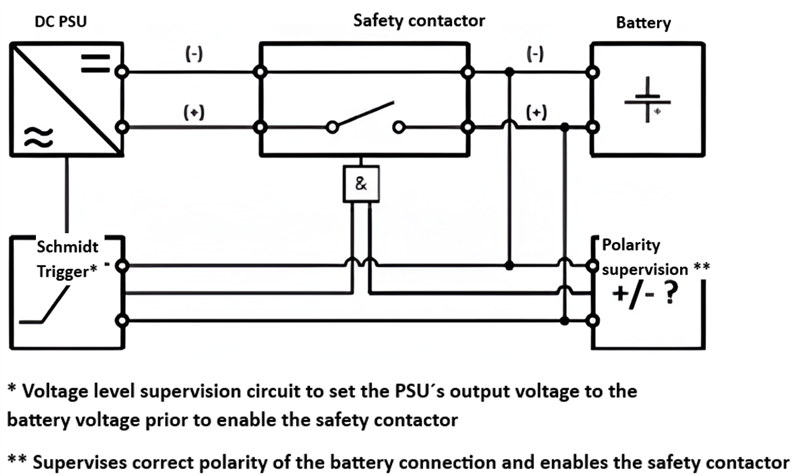

- Battery testing and simulation: The EA-PSB 10000 series is ideal for testing EV batteries at cell, module, or pack levels. It supports State-of-Health (SOH) classification, End-of-Line (EOL) testing, and integrated battery diagnostics. With precise voltage/current measurement, high reproducibility, and over 96% efficiency, it fits both automated systems and standalone setups. These power supplies also simulate single cells, modules, or whole battery packs for evaluating storage configurations and DUT performance. Built-in OCP, voltage monitoring, and alarm functions ensure safe and accurate testing, acting like a virtual battery with protective features.

Figure 1. Ideal setup for high-power battery charging and management using bidirectional programmable DC power supplies (image source)

- Fuel cell emulation: The EA-PSB 10000 series provides high-accuracy testing for fuel cells, stacks, and full systems. It efficiently measures resistance, performance, and lifespan. Parallel connection in master-slave mode supports high current applications while maintaining precision and feedback efficiency.

- Electric vehicle and Onboard Charger (OBC) testing: Modern EV systems often recover energy through regenerative braking or bidirectional chargers. For onboard charger (OBC) testing, the EA-PSB 10000 enables dynamic, accurate data capture using built-in sequencing and logging. Its adjustable control frequency (Normal, Fast, Slow) prevents loop conflicts with the DUT, ensuring compatibility and reproducibility.

- Photovoltaic (PV) Inverter Testing: The EA-PSB 10000 series simulates PV arrays using programmable IU curves compliant with EN 50530 and Sandia models. It factors in irradiation, shadow, and weather effects and supports static/dynamic MPPT testing. Its 16-bit resolution and 100ms sampling provide accurate, exportable results.

- Battery recycling: Before EV batteries are recycled, they need to be safely discharged. These supplies support the second-life evaluation of retired EV batteries via SOH checks and full discharge if necessary. The process is safe, thorough, and cost-effective, with auto-ranging that maintains a high load current even at low voltages (<2V) for efficient low-voltage discharge and 96% regenerative feedback to the grid.

Product family highlights: EA-PSB 10000 series

Let’s briefly touch on what makes the PSB 10000 2U and 3U units from EA Elektro-Automatik stand out without diving into a specs list. Think of these as modular platforms that scale with your needs:

- EA-PSB 10000-2U models (up to 3 kW) are excellent for benchtop or small-scale applications. They offer a full feature set in a compact footprint, making them ideal for labs and R&D environments.

- EA-PSB 10000-3U models (up to 15 kW per unit) are designed for high-power test setups, including complete EV battery modules or solar array simulations. These rack-mounted units can be paralleled using a Master-Slave configuration. With the 3U devices can parallel up to 960kW and 32,640A. 1.92MW and 64kA can only be achieved with the 4U devices.

The essential features remain consistent regardless of the unit: auto-ranging flexibility, energy regeneration, and a user-friendly interface with a 5-inch touch TFT display. Standard interfaces like USB, Ethernet, analog I/O, and optional slots for CAN, EtherCAT, or Modbus ensure seamless integration into diverse test environments.

Conclusion

The programmable bidirectional DC power supply is not just a next-generation bench instrument—it is a platform for designing and validating the future of energy systems. Whether simulating battery behaviour, evaluating a solar inverter, or stress-testing EV powertrains, a solution like the EA Elektro-Automatik PSB 10000 series arms engineers with the precision, flexibility, and efficiency needed to take prototypes to production.

For more Power Supplies from EA Elektro-Automatik Shop Now

About the Sponsor

The EA Elektro-Automatik Group is Europe’s leading supplier in the area of power electronics for R & D and industrial application. At the headquarter in Germany in the industrial centre of North Rhine Westphalia 450 qualified associates, in a facility of 19000 m², research, develop and manufacture high-tech equipment for power supplies, high power mains adaptors and electronic loads with or without power feedback. For more information, click here

Featured Product

|

EA-PSB 10200-50 2U, Modular Power Supply, 1 Output, 3 kW, Programmable, 0 V, 200 V, 50 A

|

Related Products

|

EA-PSB 10360-15 2U Modular Power Supply, 1 Outputs, 1.5 kW, Programmable, 0 V, 360 V, 15 A

|

EA-PSB 10010-120 2U Modular Power Supply, 1 Outputs, 1.2 kW, Programmable, 0 V, 10 V, 120 A

|

EA-PSB 10010-60 2U Modular Power Supply, 1 Outputs, 600 W, Programmable, 0 V, 10 V, 60 A

|

EA-PSB 10750-06 2U Modular Power Supply, 1 Outputs, 1.5 kW, Programmable, 0 V, 750 V, 6 A

|