Introduction

Introduction

In today's business environment, applications in military, aerospace, automotive, industrial, and medical technology demand high-functioning, commercial-standard interconnect solutions. The electronic systems in these applications require highly ruggedized connectors for reliable data flow and power. In these industries, interconnects operate under harsh conditions, including extreme temperatures, vibration, electromagnetic interference, and exposure to corrosive substances. Therefore, robust interconnects are needed that are capable of handling higher data rates and power levels even in extreme environmental conditions without compromising with signal integrity. Standardized testing may not be sufficient to ensure the optimal performance of these Commercial Off-The-Shelf (COTS) products. Samtec has developed a "Severe Environment Testing (SET)" standard for system designers and engineers seeking additional qualification data for products used in severe environments. In this tech spotlight, you will learn about SET standards, flex stacking and design, and SET-approved connectors from Samtec.

What is Severe Environment Testing (SET)?

Severe Environment Testing (SET) is an enhanced testing protocol developed by Samtec. It was developed to test connectors beyond typical industry standards and specifications to ensure they can perform in the most challenging operational environments.

SET was developed using the VITA 47.0 – 47.3 standards, as well as feedback from industries concerning the testing of COTS products. VITA 47 is an American National Standards Institute standard that defines a set of rigorous environmental, design, construction, safety, and quality requirements for plug-in COTS hardware intended for use in mobile defense and aerospace applications. The intent of SET is to bridge the gap between a full Military Standard (MIL-STD) product and a COTS product.

Standard SET qualification tests include a combination of Low-Level Contact Resistance (LLCR), Dielectric Withstanding Voltage (DWV), mechanical shock, vibration, humidity, and temperature cycling. SET takes these standard qualification tests and expands the specifications required to pass the test, demonstrating the connector's capability for severe environments.

How is SET Different from Design Qualification Testing and Extended Life Product Testing?

Samtec includes standard Design Qualification Testing (DQT) and Extended Life Product(E.L.P.

) testing in SET and additional testing for interconnect systems. The SET goes above and beyond standard testing, especially in dielectric withstanding voltage at altitude, electrostatic discharge, temperature shock, non-operating class temperatures, and mechanical shock and vibration. Now, let's see how SET differs from DQT and E.L.P.

Mating / Unmating / Durability test: In DQT and E.L.P. testing for mating / unmating / durability of a connector, the Relative Humidity (RH) is set at a range of 90 – 98% with 100 mating and unmating cycles for 10 days at +25°C to +64°C. In SET, the RH is increased to 100% for 10 days with 250 mating and unmating cycles at +25°C to +64°C.

Temperature cycling test (Thermal shock test): This evaluates the performance of the connector set when subjected to temperature shock. A normal thermal shock test is done on the connector set from -55°C to +85°C through 100 cycles with a 30-minute dwell time at each temperature. In the SET version of this test, the temperature range is increased from -65°C to +125°C through 500 cycles with a dwell time of 30-minute During this test, the LLCR of the part under test is looked for increases in resistance.

Mechanical Shock / Random Vibration / LLCR and Event Detection testing: This test evaluates the performance of a connector set when exposed to a series of mechanical shocks and random vibrations. For mechanical shock testing, the standard test uses a 100 G half-sine peak shock for 6 milliseconds, and the SET version uses a 40G half-sine peak shock for 11 milliseconds. LLCR is used before and after the test to gauge its effects and to look for changes in the contact system resistance. The standard random vibration test uses 7.56 gRMS for 2 hours per axis, while the SET version uses 12 gRMS, 5 – 2000Hz for 1 hour per axis.

Non-Operating Class Temperature testing: In SET, a currently LLCR-tested product is exposed to two different temperature ranges for 100 cycles. The first range is from -55°C to 105°C, and the second range is from -65°C to 125°C. After exposure, the product is again tested for LLCR. It can be considered stable if it maintains a delta of <= 5 mΩ for LLCR for those temperature ranges from the start to the end of the test.

Electrostatic Discharge testing: ESD testing for SET is based on the EN61000-4-2 standard from VITA 47. The connectors under test are exposed to 5kV, 10kV, and 15kV (10 times at each level) and discharged through a 150–pf capacitor through a 330-Ω resistor. After discharging, they are then visually inspected for damage that could occur to the plating.

DWV at Altitude testing: In a typical DWV test, a testing voltage (.75 x a part’s breakdown voltage) is applied for 60 seconds to the connectors-under-test . The part is considered to pass if there are no electrical arcs. Under SET, the test is conducted with a test voltage at 300 VAC in an altitude chamber to simulate an altitude of 70,000 feet. Connector sets are considered to have passed the test if they do not break down electrically.

|

TEST |

DESIGN QUALIFICATION TESTING (DQT) |

EXTENDED LIFE PRODUCT |

SEVERE ENVIRONMENT TESTING (SET) |

|

Gas Tight |

N/A |

✓ |

✓ |

|

Normal Force |

✓ |

✓* |

✓* |

|

Thermal Aging |

✓ |

✓* |

✓* |

|

Mating / Unmating / Durability (240 Hrs) |

✓ (90-98% Relative Humidity, 100 Cycles) |

✓* (90-98% Relative Humidity, 100 Cycles) |

✓ (100% Relative Humidity, 250 Cycles) |

|

IR / DWV |

✓

|

✓* |

✓ (At Altitude of 70,000 Feet) |

|

CCC |

✓

|

✓* |

✓* |

|

Mechanical Shock / Random Vibration / LLCR |

✓ (100 G Peak, 6 ms, Half Sine & 7.56gRMS Avg, 2 Hr / Axis) |

✓* (100 G Peak, 6 ms, Half Sine & 7.56gRMS Avg, 2 Hr / Axis) |

✓ (40 G Peak, 11 ms, Half Sine & 12gRMS, 5 - 2,000 Hz, 1 Hr / Axis) |

|

Mechanical Shock / Random Vibration / Nanosecond Event Detection |

✓ (100 G Peak, 6 ms, Half Sine & 7.56gRMS Avg, 2 Hr / Axis) |

✓* (100 G Peak, 6 ms, Half Sine & 7.56gRMS Avg, 2 Hr / Axis) |

✓ (40 G Peak, 11 ms, Half Sine & 12gRMS, 5 - 2,000 Hz, 1 Hr / Axis) |

|

Temperature Cycling (500 Cycles) |

N/A |

N/A |

✓ |

|

Non-Operating Class Temperature |

N/A |

N/A |

✓ |

|

Electrostatic Discharge (ESD) |

N/A |

N/A |

✓ |

|

10 Year MFG (Mixed Flowing Gas) |

N/A |

✓ |

N/A |

|

Mating Cycles (250 to 2,500) |

N/A |

✓ |

N/A |

|

* Completed as part of initial Design Qualification Testing (DQT) |

|||

Table 1: Various test performed on Samtec’s connectors under DQT, ELP and SET.

and SET.

Join the forum discussion or comment below

The Benefits of SET Across Various Industries

Samtec's Severe Environment Testing (SET) qualified connectors support various industries operating in rugged and harsh environments. Some of the examples are mentioned here:

- Aerospace, Defense and Military: SET connectors are used in cockpit communications, missile defense, jamming equipment, 5G MIMO antennas, early warning radar systems, and land-based/in-flight/naval radar. These connectors are also approved for NASA Class D missions and are used in LEO satellites, SmallSats, CubeSats and other space exploration equipment, such as space suits.

- Automotive: In the automotive sector, SET connectors meets the crucial in connecting automotive displays and different vehicle control units. These interconnects also meet the requirements of systems supercomputers for ADAS and autonomous driving and power management in EVs.

- Industrial: SET-qualified interconnects boost manufacturing efficiencies in smart grids and factories by integrating IIoT, robotics and automation, industrial control, and artificial intelligence (AI). They also support reliable communication and power transmission between PLCs, HMIs, sensors, actuators, and industrial communication networks.

- Medical: Surgical theater equipment relies on SET-qualified connectors for everything from lighting and tables to monitors and robotics. These interconnects are widely used in medical imaging (MRIs, CT / PET Scans, and Ultrasounds) and rapid diagnostics.

- Data Centers: Samtec's SET interconnects maintain signal integrity while dramatically improving thermal design in space-constrained applications such as network switches, current and next-generation servers, and routers in modern data centers. These interconnects also provide ideal support for next-generation AI/ML topologies via AI accelerators and domain-specific architectures (DSAs).

- Instrumentation: Samtec's SET interconnects meet the requirements for testing semiconductors and complex system architectures. These rugged and high-performance connections also support the sensors, scanners, and signal converters that enable smart functionality in machines, vehicles, and devices "smart."

Flexible Stacking Interconnect Solutions

Flexible Stacking Interconnect Solutions from Samtec are exclusively designed to provide design flexibility for connecting two or more PCBs. These connectors are popular in factory automation, embedded computing, robotics, monitoring, vision systems, measurement, metering, motion and process controls, safety, and security.

Flexible stacking board to board connectors are available in various orientations such as standard, low profile, elevated, pass-through, right angle, coplanar, and bottom entry, with pitch options ranging from 0.80 mm to 5.08 mm. This versatility allows them to fit into small spaces and accommodate unique design requirements. These connectors can accommodate a wide range of board stacking distances, from as low as 1.65 mm up to 48.51 mm, with adjustable post heights in small increments.

In addition to the Flex Stack capability on terminal strips, various contact systems such as Tiger Eye, Tiger Claw

, Tiger Buy

, and Tiger Beam

are available in Samtec socket strips, offering designers greater flexibility for creative board stacking. Samtec also provides flexible stacking solutions with IDC (Insulation Displacement Connector) cable assemblies. These cable assemblies feature high-reliability contacts with a choice of pitch, socket, plug terminations, low profile, and slim body configurations.

|

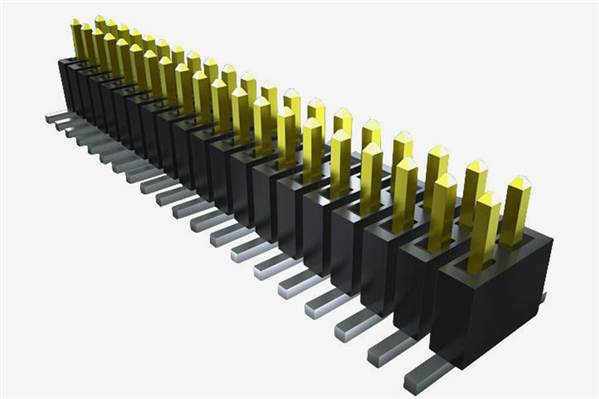

Pin Header, Board-to-Board, 2.54 mm, 2 Rows, 10 Contacts, Surface Mount |

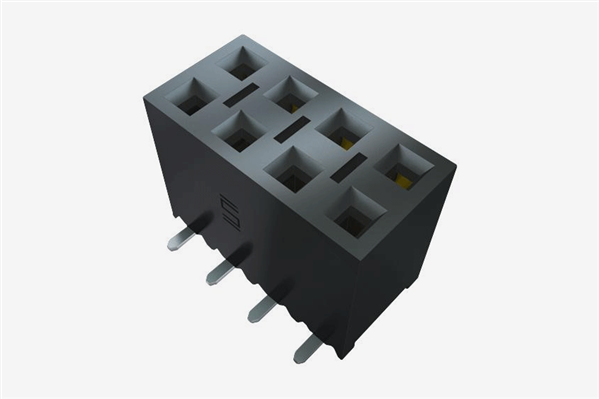

PCB Receptacle, Board-to-Board, 2.54 mm, 2 Rows, 10 Contacts, Tiger Claw |

Pin Header, Board-to-Board, Wire-to-Board, 1.27 mm, 2 Rows, 10 Contacts, Surface Mount, FTSH |

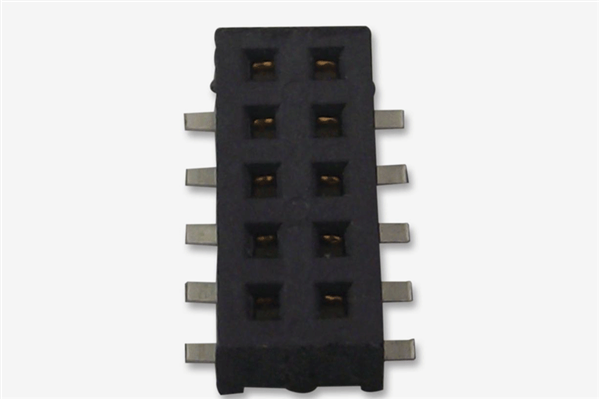

PCB Receptacle, Board-to-Board, 1.27 mm, 2 Rows, 40 Contacts, Surface Mount, CLP |

Other SET-approved connectors

We have previously discussed SET-approved Flexible Stacking connectors from Samtec. Now, have a look at what other SET-approved special connector portfolio Samtec maintains.

SFM/TFM |

SFM-105-02-L-D-A-K-TR PCB Receptacle, Board-to-Board, Wire-to-Board, 1.27 mm, 2 Rows, 10 Contacts, Surface Mount |

TFM-105-02-L-DH-TR Pin Header, PCB Header, Board-to-Board, Wire-to-Board, 1.27 mm, 2 Rows, 10 Contacts |

SEAF/SEAM |

SEAF-40-06.5-S-10-2-A-K-TR Mezzanine Connector, High-Speed, Array, Female, 1.27 mm, 10 Rows, 400 Contacts, Surface Mount |

SEAM-40-09.0-S-10-2-A-K-TR Mezzanine Connector, High-Speed High-Density, Array, Male, 1.27 mm, 10 Rows, 400 Contacts |

LSHM/LSHM |

LSHM-140-02.5-L-DV-A-S-K-TR Mezzanine Connector, High-Speed, Hermaphroditic, 0.5 mm, 2 Rows, 80 Contacts, Surface Mount |

Note: LSHM mates with itself |

ERM8/ERF8 |

ERM8-025-09.0-L-DV-K-TR CONN, STACKING, HDR, 50P, 2ROW, 0.8MM |

ERF8-025-05.0-L-DV-L-K-TR Mezzanine Connector, High-Speed, Receptacle, 0.8 mm, 2 Rows, 50 Contacts, Surface Mount |

S2M/T2M |

S2M-107-01-L-D PCB Receptacle, High-Reliability, Board-to-Board, Wire-to-Board, 2 mm, 2 Rows, 14 Contacts |

T2M-107-01-L-D-RA-WT Pin Header, High-Reliability, PCB Header, Board-to-Board, Wire-to-Board, 2 mm, 2 Rows, 14 Contacts |

UMPT/UMPS |

UMPT-04-01.5-G-V-S-W-TR Pin Header, Power Terminal, Board-to-Board, 2 mm, 1 Rows, 4 Contacts, Surface Mount Straight, UMPT |

UMPS-04-03.5-G-V-S-W-TR PCB Receptacle, Power Terminal, Board-to-Board, 2 mm, 1 Rows, 4 Contacts, Surface Mount, UMPS |

Conclusion

Interconnects in aerospace, automotive, defense, industrial, and medical applications are subjected to extreme environmental conditions. Intermittent connections may occur, which can be catastrophic in applications like aerospace, defense, or military systems, or cause unwanted downtime in a manufacturing system. It follows that highly ruggedized connectors are required for reliable data and power flow in these systems. Samtec's Severe Environment Tested (SET) and certified qualified connectors provide higher reliability in severe environments. These connectors also reduce failure risk while being cost-effective over the long term. Thus, end users can be confident when using these high-performance and tested products.

About the Sponsor

Samtec Founded in 1976, Samtec is much more than just another connector company. We put people first, along with a commitment to exceptional service, quality products and innovative technologies that take the industry further faster. This is enabled by our unique, fully integrated business model, which allows for true collaboration and innovation without the limits of traditional business models. We have over 40 global locations, New Albany, Indiana is where we are headquartered. Our product selection is extremely diverse, ranging from standard cataloged products to unique high-performance designs, Samtec's Product Solution Blocks are designed to support any interconnectivity need, regardless of application, performance requirements or environment. Read More

Samtec Founded in 1976, Samtec is much more than just another connector company. We put people first, along with a commitment to exceptional service, quality products and innovative technologies that take the industry further faster. This is enabled by our unique, fully integrated business model, which allows for true collaboration and innovation without the limits of traditional business models. We have over 40 global locations, New Albany, Indiana is where we are headquartered. Our product selection is extremely diverse, ranging from standard cataloged products to unique high-performance designs, Samtec's Product Solution Blocks are designed to support any interconnectivity need, regardless of application, performance requirements or environment. Read More

TSM-105-01-L-DV

TSM-105-01-L-DV SSM-105-L-DV-LC

SSM-105-L-DV-LC FTSH-105-01-L-DV-K-P-TR

FTSH-105-01-L-DV-K-P-TR CLP-120-02-L-D

CLP-120-02-L-D