Virtually every modern electronic device relies on power supplies, converters, and switching circuits; however, many are susceptible to electromagnetic interference (EMI) and high-voltage transients. Integrating safety capacitors into the AC input line circuitry can reduce the amount of noise that is generated, as well as block incoming noise from other devices. Most modern devices use surface-mount PCBs for benefits that include cost savings and smaller form factors. With these designs, surface-mount safety capacitors provide all the benefits of their through-hole siblings in a much smaller and cost-effective package. This Tech Spotlight discusses the basics of safety capacitors, and some of the benefits and applications of SMD (surface-mount device) safety capacitors.

What Are Safety Capacitors?

Safety capacitors are also known as EMI / RFI suppression capacitors, AC line filter safety capacitors, or X- and Y-rated capacitors. They are primarily used to reduce EMI and protect electronic devices from mains noise and high voltage surges. Safety capacitors are found in a wide range of devices in both consumer and industrial electronics.

Types of Safety Capacitors

Safety capacitors are available in through-hole and surface-mount designs. Types of through-hole safety capacitors include ceramic disk and film capacitors. A ceramic disk capacitor is a disk-shaped capacitor that uses ceramic material as the dielectric to store electric charge. A film capacitor uses a thin plastic or polymer film as the dielectric material between its two conductive plates. Ceramic disk and film capacitors are widely used in a variety of applications; however, the characteristics of through-hole components make them less versatile than a modern surface-mount device (SMD).

What are SMD MLCC Safety Capacitors?

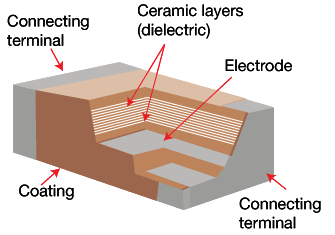

One of the most versatile and effective SMD safety capacitors is the multilayer ceramic capacitor (MLCC). MLCCs are a type of ceramic capacitor commonly used in electronics because of their compact size and high capacitance values. They consist of multiple dielectric and electrode layers within a single package. An MLCC is assembled using ceramic dielectric sheets imprinted with internal electrodes, typically composed of metals, such as nickel, silver, or palladium, in a staggered arrangement. Following a high-temperature sintering process, the ceramic sheets fuse, and the outer electrodes are sealed at both ends, forming a monolithic structure as illustrated in Figure 1. MLCCs have a low Equivalent Series Resistance (ESR), the internal resistance of a capacitor, reducing unwanted voltage drops, as well as giving them increased reliability due to minimal self-heating.

Figure 1: SMD MLCC Safety Capacitor

Source: Capacitor Ceramics - an overview | ScienceDirect Topics

The capacitance value of the component is directly linked to the number of layers, the dielectric constant, and the active area. The dielectric constant is determined by the type of ceramic material used. The active area is the overlapping region between opposing electrodes; the larger the active area, the higher the capacitance. Conversely, the thickness of the dielectric material inversely affects the capacitance value, meaning a thicker dielectric would result in a lower capacitance value. This thickness also plays an important role in determining the voltage rating of the component. Thicker dielectrics typically possess higher voltage ratings than thinner ones.

Safety Capacitors

Shop our wide variety of Surface-mount Safety Capacitors from Vishay.

Don't forget to join our discussion.

MLCCs are surface-mount components, meaning that instead of wires or leads, they have contacts, which are installed directly on top of pads on the PCB. With an automated manufacturing process, SMDs are typically mounted onto the pads using pick-and-place machines. The pads have solder paste pre-applied and once assembly is complete, the PCB is heated to melt and fuse the paste, securing the components in place. This process is called reflow soldering and is typically more precise and cost-effective than through-hole assembly. Because there are no wires, complications related to routing, bending, and clipping are eliminated. No wires also means that there are no clearance requirements for the backside of the PCB. Additionally, SMDs are significantly smaller than through-hole components, enabling the portability and compact form factors of modern electronic devices.

Operation of a Safety Capacitor

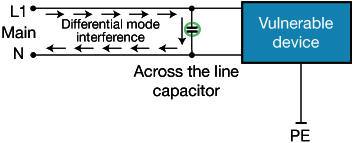

Safety capacitors provide a low impedance path for interference signals, such as common mode EMI, so that it can be shunted to chassis ground or the neutral conductor, reducing its impact. There are two major types of safety capacitors: Class-X and Class-Y.

Figure 2: Operation of Class-X (left) and Class-Y (right) Safety Capacitors (Source: Vishay)

Class-X Capacitor: Class-X safety capacitors are used to reduce differential mode EMI, where noise travels on one conductor, but not the other. If a capacitor is connected across the main supply at the component generating the EMI, then the differential mode current is offered an alternative path. Less of the interference current will flow to the vulnerable component. The international standard IEC 60384-14 classifies standard Class-X safety capacitors based on their rated AC voltage and peak pulse voltage.

| Sub Class | Rated AC Voltage | Peak Pulse Voltage (UR) |

|---|---|---|

| X1 | ≤ 760 VAC | 2.5 kV < UR ≤ 4 kV |

| X2 | ≤ 760 VAC | UR ≤ 2.5 kV |

| X3 | ≤ 760 VAC | UR ≤ 1.2 kV |

Table 1: Classification of Class- X Safety Capacitors

Class-Y Capacitor: Class-Y safety capacitors are connected from the line conductors to ground, and they help filter out high-frequency noise, spikes, and transients that can be conducted back onto the power lines. Y capacitors in EMI filters help to suppress common mode EMI, which occurs when unwanted currents travel on both the line and neutral conductors in the same direction. If two capacitors are connected, one between the line and ground, and the other between the neutral and ground, then the common mode interference currents are offered an alternative path to ground, away from vulnerable components. IEC 60384-14, classifies standard Class-Y safety capacitors into the following sub-classes based on their rated and peak pulse voltage:

| Sub Class | Rated AC Voltage | Peak Pulse Voltage (UR) |

|---|---|---|

| Y1 | ≤ 500 VAC | 8 kV |

| Y2 | ≥150 VAC / ≤300 VAC | 5 kV |

| Y3 | ≥150 VAC / ≤250 VAC | None |

| Y4 | <150 VAC | 2.5 kV |

Table 2: Classification of class-Y safety capacitors

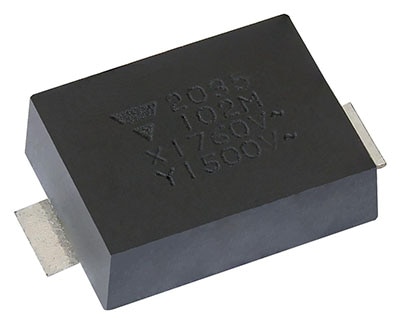

The Vishay SMD Y1 Series

The Vishay SMD Y1 Series consists of high-performance X1/Y1 SMD safety capacitors that are suitable for a wide range of applications, including EMI suppression in power supplies, line filtering, and transient protection. They are available with capacitance values ranging from 470pF to an industry-leading 4700pF. The SMD Y1 Series is also the first SMD safety capacitor rated to 500VAC and 1500VDC. SMD Y1 Series safety capacitors are capable of operating in harsh industrial environments, with a Humidity Class IIB rating (500 h at 85°C and 85% with rated voltage applied) and moisture sensitivity level (MSL) of MSL2a.

| 470 pF | Buy now | 680 pF | Buy now |

| 1000 pF | Buy now | 2200 pF | Buy now |

| 3900 pF | Buy now | 4700 pF | Buy now |

Vishay’s SMD Y1 Series of safety capacitors are suitable for all surface-mount electronics that require safety capacitors, including power supplies, smart meters, lighting, motors, variable frequency drives (VFDs), and solar inverters.

Summing Up: Protecting Components with Safety Capacitors

In partnership with

Safety capacitors help mitigate electromagnetic interference (EMI) and safeguard sensitive electronic equipment against peak impulse voltages and voltage transients. Although many safety capacitors are traditionally designed for through-hole mounting, surface-mount safety capacitors provide a variety of advantages, including a reduction in the physical space required and lower production costs. The SMD Y1 Series from Vishay offer industry-leading specifications for surface-mount safety capacitors and are highly effective in reducing noise and protecting sensitive equipment.

What types of projects or applications have you created where safety capacitors were particularly useful?

Please tell us in the Comments section below.