Cooling is one of the most important parameters in the functionality and longevity of electronic device. Many devices generate an enormous amount of heat during operation. If left unchecked, this heat can lead to reduced performance, temporary shutdown, or even complete failure. Efficient cooling solutions are indispensable for stable operation. Compact fans are the most viable solution for many types of electronic devices, as they combine high output with high efficiency, all in a miniaturized form factor. However, there are factors that complicate fan selection, including vibration, fan noise, and cost. This article delves into the different types of compact fans and discusses some useful approaches in designing and selecting the right compact fan for a particular application.

What are the different types of compact fans?

There are several types of compact fans available, with specifications, such as airflow, power consumption, and size, differing based on their design.

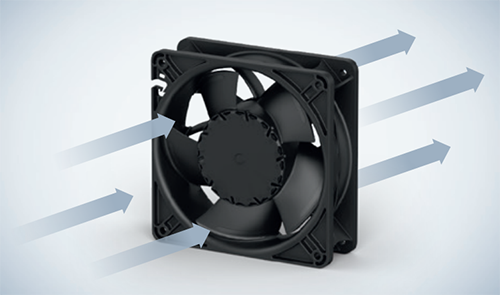

Axial compact fans: Axial fans are frequently used in exhaust applications with small airborne particulate sizes, such as dust streams, smoke, and steam. They are also suitable for ventilation applications that require reverse airflow. Axial compact fans produce airflow towards the direction of the axis of rotation. The blades of the fan force the air linearly to the shaft. Axial compact fans deliver free air with the lowest power consumption at zero static pressure. The axial design provides a high air volume combined with low pressure, and the airflow is evenly distributed in a defined area.

Figure 1: Axial compact fan (Source: ebm-papst)

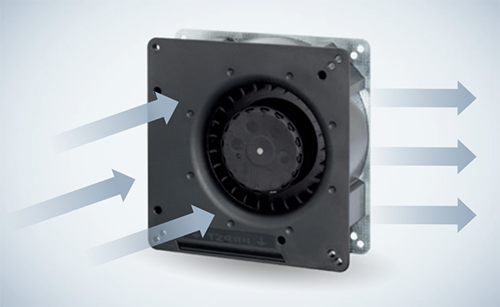

Centrifugal compact fans: Centrifugal compact fans can accommodate widely varying operating conditions and are capable of generating high pressures with high efficiencies. Centrifugal fans are favored when the cooling airflow must be deflected by 90° or extremely high pressures are needed. They typically require more power to operate than axial fans.

Figure 2: Centrifugal compact fan

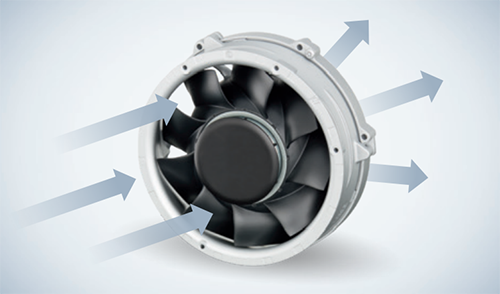

Diagonal compact fans: Diagonal compact fans are particularly suitable for intensive cooling applications with a high component concentration; an example being control cabinets. Diagonal compact fans combine the favorable properties of axial and centrifugal fans. In diagonal compact fans, air draw is axial but with a diagonal outflow. The impeller and housings are conical, resulting in greater intake air compression. The advantage of such a configuration is that the airflow is similar to an axial fan, but with a greater pressure increase and far lower operating noise.

Figure 3: Diagonal compact fan (Source: ebm-papst)

How do you Choose the Right Type of Fan?

Choosing the right type of cooling fan for a specific application ensures the most efficient cooling and ventilation. The following are important considerations when choosing a fan:

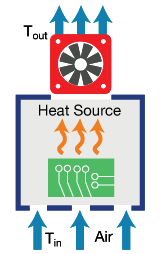

Thermal analysis: Determining the amount of heat generated inside the equipment is a factor in calculating the volume of air required to be moved to maintain a proper operating temperature. Temperature, thermal resistance, and heat dissipation are all contributing factors. Thermal analysis can be done using temperature sensors, such as thermocouples or RTDs, as well as computational fluid dynamics.

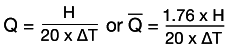

Calculation of Required Airflow: The following equation estimates the required airflow based on the amount of heat generated and the maximum permissible temperature increase value within the system:

where Q = Airflow(m3/min), = Airflow (cubic feet per minute ) ,H = Total heat generation(W) and ΔT = Temperature rise value(°C).

Figure 4: Calculation of Required Airflow for Cooling

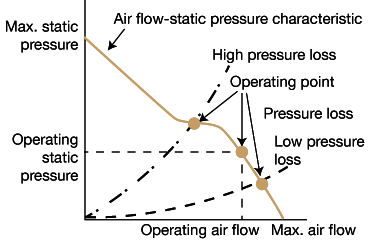

System Impedance: A cooling system will lose air pressure when air is pulled in and pushed out with a cooling fan. This pressure loss varies with airflow and is known as system impedance. The designer must know the system air resistance curve to specify the cooling per slot.

System Operating Point: The system operating point is the intersection point of the system impedance curve and the selected fan air performance curve. This is the optimal working point for fans in the system, where the change in the slope of the air performance curve is minimized and the change in the slope of the system impedance curve is at its lowest.

Figure 5: System Operating Point (Source: engineersedge.com)

Because it is difficult to calculate the system pressure loss, a fan with 1.5 to 2 times the required airflow is generally recommended.

What are the Challenges of Designing a Compact Fan?

Designing a compact fan requires a fundamental understanding of the system's operational requirements and factors, including the airflow rate, temperature, pressure, and the properties of the airstream. The following are the key criteria for designing a compact fan:

Fan laws: Fan laws, also known as the "affinity laws" or "fan performance laws," are fundamental principles that describe how the performance of a centrifugal fan or pump changes when certain parameters are modified. These laws provide insights into the behavior of fans and pumps and are importnat for designing, analyzing, and optimizing these systems. There are typically three main fan laws:

The Law of Affinity for Speed:

This law describes how changes in the rotational speed of a fan or pump affect its performance. It states that the flow rate (Q), pressure (P), and power (P) of the system are directly proportional to the change in speed (N) if all other parameters remain constant. Mathematically, it can be expressed as:

Q₂ / Q₁ = N₂ / N₁

P₂ / P₁ = (N₂ / N₁)²

P₃ / P₁ = (N₂ / N₁)³

This law is commonly used to estimate the effect of changing fan or pump speed on flow rate, pressure, and power consumption.

The Law of Affinity for Flow Rate:

This law explains how variations in flow rate (Q) impact the performance of a fan or pump. It states that flow rate, pressure, and power are directly proportional to the square of the change in flow rate if other parameters are held constant. Mathematically, it can be expressed as:

P₂ / P₁ = (Q₂ / Q₁)²

N₂ / N₁ = (Q₂ / Q₁)½

This law is useful for predicting the impact of flow rate changes on pressure and power requirements.

The Law of Affinity for Pressure:

This law details how variations in pressure (P) affect the performance of a fan or pump. It states that pressure, power, and flow rate are directly proportional to the square of the change in pressure if other parameters are unchanged. Mathematically, it can be expressed as:

Q₂ / Q₁ = (P₂ / P₁)½

N₂ / N₁ = (P₂ / P₁)⅔

This law is helpful for predicting how changes in pressure affect flow rate and power consumption.

Noise: A high noise level marks inefficient operation and can cause fatigue. Fan noise is mainly caused by two mechanisms. The first is the noise generated directly by air movement and the associated pressure fluctuation. The second is noise resulting from the contact or rubbing of solid bodies. Noise may also arise from the integrated power and control electronics. Fan noise can be minimized by aligning the blades and struts. Finely balanced rotors with maintenance-free ball bearings also minimize vibration and reduce impact sound.

Durability: Compact fans may be deployed in challenging environments, such as high temperatures, dusty conditions, or corrosive atmospheres. Moisture and particulate content are important considerations in selecting fan type. Contaminant build-up on fan blades can cause severe performance degradation, fan imbalance, and drivetrain wear. Worn bearings can also result in unsatisfactory noise levels and the risk of seizure. To enhance the fan's durability, it should be cleaned regularly, and bearings should be monitored frequently.

Efficiency: The efficiency of a compact fan is the ratio of the power imparted to the airstream to the power delivered by the motor. An essential aspect of a fan performance curve is the optimal efficiency point, where a fan operates the most cost-effectively in terms of maintenance considerations, energy, and efficiency. In order to increase the efficiency and minimize the power consumption of a compact fan, every component must be optimized, and particular attention must be paid to how well the individual components interact.

Size: The size of a fan plays a significant role in determining its power consumption. larger fan consumes more power compared to smaller ones. Similarly, the space requirement to install a fan is also important when selecting a cooling fan. Many designers select oversized fans to accommodate uncertainties in system design or future capacity increases. This practice leads to high energy costs and requires added space for installation. A more reasonable approach is to carry out an individual evaluation of the system to determine an appropriate fan size.

How to Select the Ideal Fan with ebm-papst FanScout Software

Compact Fans

Shop our wide variety of Compact Fans from ebm papst.

Don't forget to join our discussion.

To find the ideal compact fan for any application, ebm-papst also offers FanScout, a comprehensive fan selection software. FanScout provides reliable and extremely precise data based on real measured values. The minimum input data for selecting suitable fans are the operating points and times. In addition, information about the available installation space, redundancy requirements, or the maximum permitted number of fans can also be taken into consideration. Based on these specifications, FanScout performs comprehensive calculations for all possible combinations to determine their expected annual energy consumption. To simplify the decision further, FanScout also considers life cycle costs, from the purchase price to operating and service costs.

The New Generation of Compact Fans from ebm-papst

ebm-papst’s S-Panther and AxiForce series of compact fans offer low noise emissions without compromising air performance or efficiency. The S-Panther fan has a unique strut design with winglets and a turbulator, which assists in dissipating large quantities of heat from confined spaces. The high-efficiency GreenTech DC motors and new aeroacoustic design improve the fan’s efficiency, as well as reduce noise by up to 9 dB(A). S-Panther fans are well-suited for variable frequency drives (VFD), welding machines, solar inverters, and telecommunications applications.

Compared to its predecessor, the AxiForce 80 fan provides an increase in efficiency of up to 42% at an operating point of 108 m³/h at 285 Pa back pressure. It has aerodynamically optimized fan impellers and fan housings that reduce noise emission by 7 dB(A).

Summing up: Industrial Compact Fans

In partnership with

The lifetime and reliability of electronics are greatly extended with proper cooling and airflow, a goal that is best achieved with the integration of a fan. Industrial compact fans come in various designs that offer efficient airflow in a compact size. Aerodynamically-optimized compact fans from ebm-papst ensure high efficiency with consistently low noise. Due to their rugged design and low power consumption, these industrial compact fans are ready take on even the most unusual deployment and environmental condition.

What are some of the projects you've done that required a cooling fan because it generated so much heat?

Please tell us in the Comments section below.