RF cable assemblies perform an essential function in modern communication and technology systems. They transfer high-frequency signals with minimal loss and interference across various applications, ensuring signal integrity and performance. Several factors determine the quality of these cable assemblies, such as connectivity, cable construction, shielding effectiveness, manufacturing processes, to name a few. If they are damaged during setup or use, premature failures may occur, resulting in signal loss, impedance mismatches, or increased maintenance.

Emerging technologies such as 5G mmWave add extra complexity to the design and production of RF cable assemblies. Challenges include choosing suitable materials, managing tool costs, and traceability. When building these assemblies, it is essential to consider how the materials work together, the signal attenuation within the cable, cable leakage, cable durability, and environmental tolerance. This article highlights the challenges in building these cable assemblies. It also introduces a solution offered by the Molex, the RF Cable Assembly Configurator, that automates the process of manufacturing RF cable assemblies.

The Types of RF Cable Assemblies

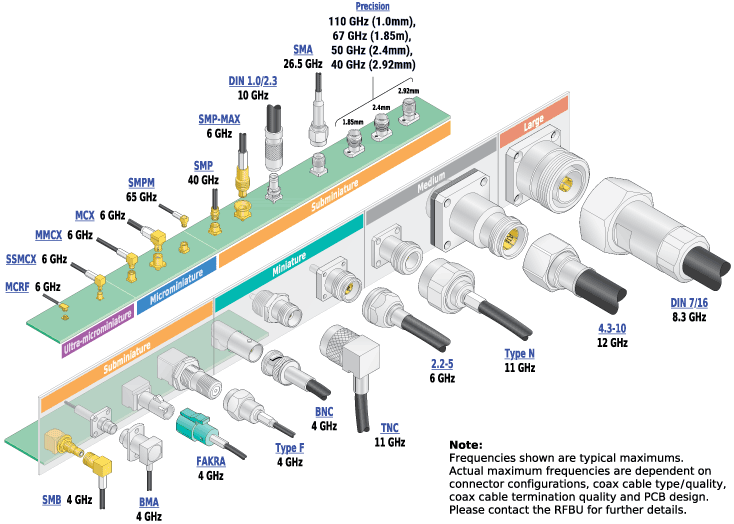

Manufacturing RF cable assemblies are often challenging, especially when intricate or miniature configurations are needed. One must carefully manage factors such as frequency range, voltage standing wave ratio (VSWR), and insertion loss for optimal performance. They need to be compatible with frequencies ranging from a few hundred hertz to gigahertz with minimal signal loss or distortion, as seen in Figure 1. For example, Molex's BNC Mini RF Cable Assemblies are tailored to exceed requirements for serial transmission of 8K HDTV video, ensuring future bandwidth expansion without hardware alterations. Additionally, impedance matching is vital for minimizing signal loss, with connectors and cables engineered to work together for the best efficiency.

Figure 1: RF cable assemblies vary by connector size, maximum supported frequency, and other standards. Image source: Molex

Shielding is critical for reducing interference in RF cable assemblies. Some shielding, such as metallic braids are strong, while others, such as foil, offer flexibility. Sometimes, you need unique solutions for specific jobs, such as cable assemblies for medical applications. Impedance matching is another vital factor. RF signals are prone to interference if the impedance mismatches along the signal line. To minimize signal loss, MCX and MMCX assemblies offer solutions for different cable types and impedance options, including 50-Ohm and 75-Ohm configurations.

Figure 2: Molex 73230-6260 RF / Coaxial Cable Assembly, 90° MCX Plug to MHF4 Plug

Physical constraints such as limited space and environmental hazards require flexible solutions. For instance, defense applications need compact solutions such as SSMCX cable assemblies with small connectors. Extreme temperatures and vibration in outdoor telecom applications need durable materials such as Temp-Flex FEP for cable jackets.

Figure 3: Molex 73230-6240 RF / Coaxial Cable Assembly, MHF1-Type Plug to SMA Bulkhead Jack

5G RF connector and cable assembly solutions are ideal for next-generation mobile network equipment in a small form factor with best-in-class passive intermodulation (PIM). This characteristic enables wireless service providers to build networks capable of low-PIM performance (160 dBc @ 2x43 dBm) while decreasing operational expenditures by reducing tower loading by 30%, compared to DIN 7/16 connectors.

The Configurator: Building RF Cable Assemblies, Faster and Easier

Molex's RF Cable Assembly Configurator automates cable assembly manufacturing and ordering. It is easy to use and allows engineers to customize RF cable assemblies with a wide selection of connectors, such as SMA, SMB, BNC, and more. The configurator instantly creates concept drawings and 3D models, speeding up the design process. You can see what your assembly will look like in real time and get quick price quotes, which helps you make informed decisions, reducing time to market and minimizing errors. Furthermore, the configurator provides detailed documentation and compatibility information for each component to assure traceability.

Features

- Step-by-step guide: The configurator takes you through a series of prompts, making it easy to design for beginners.

- Interactive Selection: With real-time updates and visual feedback, you can interactively select cable types, connector styles, and impedance options.

- Component Compatibility: The configurator checks for component compatibility and provides recommendations to ensure that selected components work seamlessly together.

- Bill of Materials (BOM): The tool generates a detailed Bill of Materials (BOM), including part numbers, quantities, specifications, and pricing information for the configured assembly.

- CAD Models: You can download CAD models and drawings of the configured RF cable assembly for design integration and visualization.

- Ordering Integration: You can even order directly from the configurator, making the procurement process smoother.

Overall, the Molex RF Cable Assembly Configurator makes customization easy to use, saves time, and reduces mistakes. You can design and order customized RF cable assemblies quickly and efficiently, ensuring they work perfectly for your needs.

Figure 4: Molex RF Cable Assembly Configurator

Start configuring your custom RF cables here

Building RF cable assemblies comes with challenges from ensuring superior quality and reliability to dealing with technological complexities and complying with industry standards. Factors such as frequency compatibility, impedance matching, shielding, and physical constraints must be managed to ensure optimal performance. Collaborating with an experienced cable assembly manufacturer innovation can be invaluable for achieving these goals. The Molex RF Cable Assembly Configurator streamlines the design, building, and ordering process of RF cable assemblies.

For more varieties of RF Coaxial Cable Assemblies from Molex Shop Now

About the Sponsor

As a leading provider of interconnect solutions, Molex has more than 80 years of experience delivering connectivity at scale. Our commitment to the highest-quality products, unmatched engineering expertise and truly collaborative customer relationships spans industries, from automotive to telecommunications, mobile devices, data center, industrial, medtech and more. For more information, go here.