Introduction

Capacitors store and release electrical energy, stabilize voltage, filters noise, and manages circuit power flow. They reduce ripples in power supplies, couple signals, and time signals in oscillators. Various types of capacitors occupy different positions in a circuit depending on their respective strengths. The most used capacitors in modern electronics are multi-layer chip capacitors (MLCCs) and ceramic capacitors. However, polymer capacitors offer advantages such as low equivalent series resistance (ESR), high ripple current handling, and reliability. This makes them ideal for compact, high-performance applications like smartphones and automotive electronics, balancing cost and efficiency. This article discusses the fundamentals of polymer capacitors, their types, and benefits.

What Are Polymer Capacitors?

Polymer capacitors (also known as polymer electrolytic capacitors) are capacitors that use conductive polymers as electrolytes. Compared to ordinary electrolytic capacitors, which use liquid or gel electrolytes, these capacitors run on solid polymer electrolytes. The use of solid electrolyte makes them burst free, as there is no possibility of electrolyte evaporation due to overheating. These capacitors are manufactured by a special processing technique called polymerization. In this process, liquid chemicals called monomers are placed in the separator paper and heated to about 100°C.This heating causes a chemical reaction that hardens the monomer into a solid polymer, which remains solid permanently.

The electrical conductivity of polymer electrolytes() is several orders of magnitude higher than that of MnO2 or liquid electrolytes. For example, PEDOT: PSS exhibits conductivity values of approximately 10³ S/cm, while typical liquid electrolytes achieve conductivity values around 10⁻² S/cm. As a result, conductive polymer capacitors offer direct benefits like lower ESR, improved capacitance retention at high frequencies, a wider voltage range, and high reliability. Conductive polymer capacitors require a lower level of DC voltage derating compared to MnO2 devices. These capacitors are designed to operate at up to 105 °C in long term applications. Some special grades (like T50, T54) can operate at up to 125 °C. Another feature of conductive polymer capacitors is the absence of an ignition failure mode due to the lower oxygen content.

Operation of Polymer Capacitors

A polymer capacitor consists of an anode, a cathode, and a polymer electrolyte that work together to provide superior energy storage performance. The anode foil, typically made from aluminum, undergoes roughening to maximize surface area, followed by anodic oxidation to form a thin dielectric layer —aluminum oxide (Al₂O₃) for aluminum capacitors or tantalum pentoxide (Ta₂O₅) for tantalum capacitors.

The conductive polymer electrolyte, such as polypyrrole (PPy) or PEDOT: PSS, serves as the cathode material and penetrates the pores of the oxide layer to create a solid interface. This conductive polymer cathode provides exceptional electrical conductivity and enhanced charge transfer capabilities compared to traditional liquid electrolytes. A cathode foil or current collector, usually another aluminum layer, connects to the polymer cathode to complete the electrical circuit.

When voltage is applied to a polymer capacitor, the anodic oxide layer (Al₂O₃) on the anode foil acts as a dielectric barrier, causing positive charges to accumulate on the anode and negative charges on the polymer cathode. The polymer dielectric significantly enhances the overall dielectric constant, improving capacitance while maintaining exceptional breakdown strength. Energy storage occurs in the electric field established across the dielectric, with the polymer allowing for thinner dielectric layers and higher breakdown voltages, ultimately increasing stored energy density.

(a)

(b)

(c)

Figure 1: Basic model (a), basic structure (b) and construction (c) of a polymer capacitor (Source: Structure of Aluminum Electrolytic Capacitor | Nippon Chemi-Con Corporation)

Types of Polymer Capacitors

There are three main types of polymer capacitors based on the electrolytic and electrode materials: aluminum conductive polymer capacitors, polymer tantalum capacitors, and hybrid conductive polymer aluminum capacitors.

Aluminum conductive polymer capacitors: These use an aluminum oxide layer as the dielectric and a conductive polymer (e.g., polypyrrole (PPy) or polythiophene (PEDOT)) as the electrolyte. They have an aluminum cathode and a long useful life of up to 5,000 h. Aluminum conductive polymer capacitors can withstand high voltages up to 80V and have a ripple current capability of 5,400mA. They are used in industrial, mobile, and consumer electronics applications.

Polymer tantalum capacitors: These are solid electrolytic capacitors with a tantalum anode, tantalum pentoxide (Ta2O5) as the dielectric, and a conductive polymer cathode, designed for applications where space and reliability are critical. They offer ultra-low ESR ( typically 10 % lower than MnO2 tantalum capacitors), high capacitance , and voltage ratings up to 75 V, ensuring high volumetric efficiency and stable performance in harsh environments up to 125°C. They are used in high end server motherboards, MIL-STD-704 power supplies, phased array radar, network infrastructure, energy storage, power conditioning, decoupling, smoothing, filtering, hold-up, and other applications.

Conductive polymer hybrid aluminum electrolytic capacitors: These capacitors use a solid polymer electrolyte with a small amount of liquid electrolyte. The liquid portion of the electrolyte can withstand high voltages (up to 80 V) and provide higher capacitance ratings due to its large effective surface area. These capacitors offer a higher lifetime (up to 10,000 h), high ripple currents, and high soldering heat resistance. They are used for automotive, IT, telecommunication, and industrial applications like motion control, SMPS, automation systems, and renewable energy equipment.

Application Focus: Low ESR Capacitors Can Improve Circuit Power Efficiency and Increase Long Term Reliability

In theoretical language, a capacitor is treated as an ideal device that contributes only capacitance to the circuit and exhibits no resistance. However, all capacitors are constructed of materials with finite electrical resistance, which means they contain some ESR in addition to their other properties. The ESR of a capacitor is the internal resistance that appears in series with the device's capacitance.

Almost all capacitors exhibit this property to varying degrees depending on their construction, dielectric materials, quality, and reliability. ESR value range from a few milliohms to several ohms, resulting in power losses and reduced efficiency. It also affects the magnitude of charge and discharge currents as the capacitor does its work. Increases in temperature and frequency, bad connections, and drying of the capacitor electrolyte solution increase the ESR value.

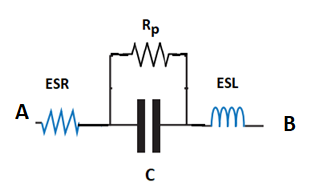

Figure 2 represents the equivalent circuit of a capacitor, where A and B are the capacitor terminals. The circuit includes the effective resistance, and some parasitic inductance (ESL) due to electrodes, leads, and geometry. The shunt resistance(insulation resistance) accounts for the DC leakage current. Heat is generated in the ESR from ripple current and in the shunt resistance by voltage.

ESR is the real resistive component of the complex impedance Z(Ω) = R + j X(Ω) of the device. This complex impedance can involve several relatively minor capacitances. These small deviations from the ideal behavior of the device can become significant when operating under certain conditions, i.e., high frequency, high current, or temperature extremes. ESR is often represented in the mathematical relationship:

ESR = DFXc = DF/2πfC ……………………(1)

where, DF is dissipation factor, and Xc is capacitive reactance in ohms

Figure 2: Equivalent circuit of a capacitor

A lower ESR improves capacitor performance by minimizing power loss, reducing heat generation, and making it suitable for high temperature applications. Also, a lower ESR reduces the high-frequency noise across the capacitor, increasing filtering effectiveness. It also allows for higher ripple current handling, leading to greater efficiency and a longer lifespan for electronic devices.

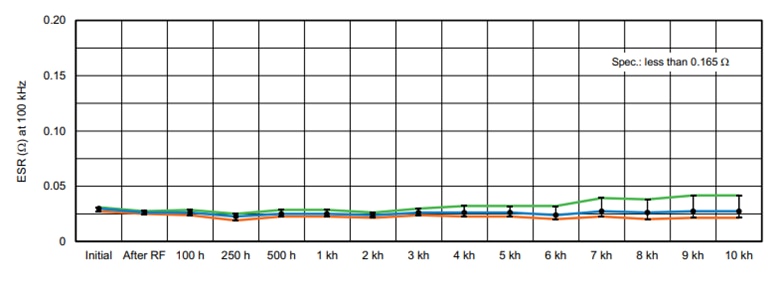

Polymer capacitors have lower ESR because they use inherently conductive polymer (ICP) materials as electrolytes. The electrical conductivity of ICP is several orders of magnitude higher than that of its liquid counterpart. The presence of ICP in the electrolyte of these capacitors offer a much more efficient path for charge transfer, providing superior conductivity and drastically reducing internal resistance. Figure 3 displays the kind of long term stability seen in polymer technology, with minimal change in ESR over time.

Figure 3: Long term stability of a polymer capacitor, with change in ESR over time (Source: Vishay)

Conclusion

Polymer capacitors feature high volumetric efficiency, allowing smaller devices to have higher capacitance values. These low-ESR capacitors reduce heat generation within the capacitor, thereby improving overall circuit efficiency and long-term reliability. Reductions in ESR also enhance the capacitor's ability to supply higher currents during charge and discharge cycles, thus improving circuit performance. Vishay offers polymer capacitors in a variety of surface-mount case sizes for applications such as military systems, portable consumer devices, computers, automotive systems, network infrastructure equipment, telecommunications equipment and many others.

For more polymer capacitors have low ESR from Vishay Shop Now

Main Featured Products

VISHAY Tantalum Polymer Capacitors

T55D337M2R5C0007 Tantalum Polymer Capacitor, 330 µF, ±20%, 2.5 V, D, 7000 µohm, 2917 [7343 Metric] |

T51D227M6R3C0040 Tantalum Polymer Capacitor, 220 µF, ±20%, 6.3 V, D, 0.04 ohm, 2917 [7343 Metric] |

VISHAY Aluminium Polymer Capacitors

MAL218097504E3 Polymer Aluminium Electrolytic Capacitor, 100 µF, 16 V, Radial Can - SMD, 2500 hrs @ 105°C |

MAL218497901E3 Polymer Aluminium Electrolytic Capacitor, 4.7 µF, 100 V, Radial Can - SMD, 0.1 ohm |

VISHAY Hybrid Polymer Aluminium Electrolytic Capacitors

MAL218297604E3 Hybrid Aluminium Electrolytic Capacitor, 220 µF, ±20%, 25 V, Radial Can - SMD, 0.027 ohm |

MAL218297103E3 Hybrid Aluminium Electrolytic Capacitor, 33 µF, ±20%, 50 V, Radial Can - SMD, 0.04 ohm |

About the Sponsor

Vishay Intertechnology, Inc. is one of the world's largest manufacturers of discrete semiconductors (diodes, MOSFETs, and infrared optoelectronics) and passive electronic components (resistors, inductors, and capacitors). These components are used in virtually all types of electronic devices and equipment, in the industrial, power supplies, automotive, computing, consumer, telecommunications, military, aerospace, and medical markets. Vishay’s product innovations, successful acquisition strategy, and "one-stop shop" service have made it a global industry leader. For more information, click here.