Take the Poll | Join our Discussion

sponsored by

Climate Control for Electronics in Harsh Conditions

Manufacturers of electronic equipment and circuits specify an operating temperature range to ensure their product's reliability, performance, efficiency, and physical integrity. Extreme temperatures can damage circuit components and deteriorate performance. An effective cooling strategy is needed to tackle heat management, as enclosure-confined equipment and circuits often generate excessive waste heat. On the flip side, low-temperature climates may require heated enclosures to avert component failure, as moisture around the components accumulates via condensation. Moisture buildup can also affect circuit components in poorly insulated enclosures and those installed outdoors. This article discusses ten methods of keeping circuits in their optimal operating environments, even when they are installed in harsh environments.

What Is Climate Control?

Climate control is a technique for temperature and humidity control within an electronic enclosure. In automated systems, sensors continuously measure the air temperature inside the enclosure and adjust airflow and temperature through heating and air-conditioning systems. Enclosures can also utilize passive climate control methods such as heat sinks, natural convection, and air vents.

10 Ways to Control Climate Inside an Enclosure

1. Heat Sinks

Heat sinks are high surface area metal components that touch the heat source to eliminate heat primarily via conduction and, occasionally, through radiation or natural convection. Heat sinks are often designed with multiple fins to increase surface area. Copper or aluminum are often the favored heat sink materials, due to their relatively high thermal conductivity and heat dissipation efficiency.

2. Natural Convection

Natural convection is a method of enclosure cooling through the surface of the enclosure. It occurs when warm air surrounding a heat source rises to the ceiling of the enclosure with cooler air taking its place. Such constant air exchange initiates airflow and heat extraction. Louvers near the enclosure ceiling permit the hot air to escape, and grilles close to the floor introduce cooler external air.

Natural convection has several limitations, including low airflow rates, which can lead to limited heat load. Louvers and grilles are effective for NEMA 1 enclosures with small heat loads found in climate-controlled spaces. Such spaces should be kept dry and clean.

3. Forced Convection (Fans)

Forced convection is best suited when natural convection cannot manage excess heat loads. A dust filter-equipped fan or similar air-moving device increases the cooling rate by increasing the airflow across the enclosure components. Fans share limitations with natural convection.

4. Heat Exchangers

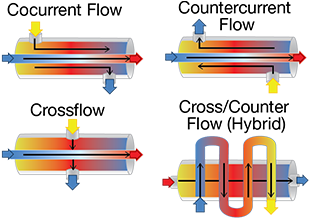

Heat exchangers, like fans, are in use only where the maximum ambient temperature is less than the maximum enclosure temperature. They are refrigerated closed-loop systems where the isolated cool enclosure air maintains the NEMA rating. Figure 1 illustrates various flow configurations.

Figure 1: Different Flow Configurations of a Heat Exchanger

Source: Thomas Publishing

A heat exchanger's construction dictates its use with a NEMA 4, NEMA 4X, or NEMA 12 enclosure in an indoor or outdoor application.

5. Air Conditioning

Air conditioning is an efficient but complex cooling system that makes the air colder than the ambient temperature. An AC runs a closed-loop, sophisticated refrigeration cycle that uses an expansion valve and a refrigerant compressor, resulting in lower evaporator coil refrigerant temperatures and higher condenser coil refrigerant temperatures.

6. Vortex Cooler

Vortex coolers are an alternative to air conditioners. A vortex cooler uses a vortex tube to create a vortex from compressed air, and separates it into hot and cold air streams. They are not closed-loop systems, as the air inside the enclosure replenishes. The availability of adequate compressed, clean air dictates whether an enclosure vortex cooler is suitable with a NEMA 4, NEMA 4X, or NEMA 12 enclosure in outdoor or indoor applications.

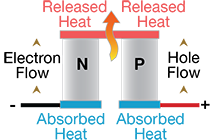

7. Thermoelectric Coolers

Thermoelectric coolers are solid-state heat pumps that employ the Peltier Effect, as shown in Figure 2. The Peltier Effect states that when a current flows through two different conductors, a heating effect occurs in one junction, while a cooling effect occurs in the other. Thermoelectric coolers are AC replacements. They do not use chlorofluorocarbons and can access NEMA 4, NEMA 4X, and NEMA 12 enclosures. Compact thermoelectric coolers are compatible with smaller enclosures.

Figure 2: The Peltier Effect in a Thermoelectric Cooler

Source: Thakor, Hadia, and Kumar/ResearchGate

8. Heaters

Heaters generate heat to maintain a safe, constant temperature to protect electronic and electrical components from extreme cold temperature-related complications.

9. Hygrostats/Hygrotherms

A Hygrotherm or Hygrostat is a device that senses ambient temperature and relative humidity inside an enclosure. They are designed to regulate the internal temperature or humidity by turning on heaters or fans at set points.

10. Ventilators/Breathers

Ventilators allow enclosures to breathe by allowing air to pass through a vent, equalizing internal and external pressure and temperature, and helping to prevent condensation. Breathers also allow air to pass through, enabling controlled pressure compensation due to temperature variations (i.e., night/day operation).

Choosing a Climate Control System

The choice of climate control system is determined by various factors, including the environment, enclosure size, humidity levels, power options, and cost, as well as the type and durability of the equipment housed in the enclosure. The size of the climate control system also must be determined.

Sizing an Air Conditioner

The required size of an air conditioner is calculated by determining the internal heat load that must be dissipated, the exposed surface area of the enclosure, and the maximum allowable differential between the internal and external temperature. This site illustrates and details the calculation.

Sizing Blowers and Fans

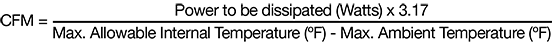

The following formula can be used to determine the CFM (cubic feet per minute), however it may not be accurate for non-standard situations, such as during instances of high air density. Ambient Temperature must be lower than the maximum internal temperature for the fan or blower to be effective.

Note: The calculation above is exact, but according Hammond, adding 25% to the CFM level is a standard safety factor.

For instances of high air density (noticeably higher than 0.075 lbs per cubic foot), the following formula can be used:

![]()

Climate Control

Shop our wide variety of Thermal Management Products by Hammond.

Don't forget to take our poll.

Optimization of Airflow

Airflow (air speed) is the starting point for all thermal management for electronics within protective enclosures. In many cases, proper airflow throughout and within the enclosure can sufficiently cool sensitive electronics. Equipment must be a sufficient distance apart for natural convection within the cabinet. Hotspots are a common problem that occur when heat sources within the enclosure do not receive sufficient air flow. In an air-conditioned enclosure, hotspots may prevent the transfer of heat through enclosure walls. Circulation fans can reduce or eliminate hotspots by moving air in adequate quantities throughout the volume of the enclosure. For optimum airflow, both the exhaust and the intake of the AC should be free of obstructions.

Hammond Climate Control Products

Hammond provides a variety of climate control products for enclosures, including air conditioners, heaters, fans, heat-dissipating enclosures, and hygrostats/hygrotherms. They also offer web-based software where the user can input a project's specifications and receive recommendations on products and sizing.

Climate Control Sizing Software

Hammond’s Climate Control Sizing Software is web-based software to help a user determine what type of climate control is needed for electrical/electronic enclosures. Input component losses can be input directly or chosen from a pre-loaded database. The environment can also be specified, along with solar loading and insulation. Recommendations cover a wide range of climate control products.

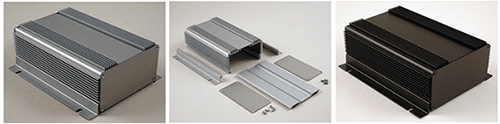

Heat Dissipating Enclosures (Heat Sinks)

Hammond's Extruded Aluminum Enclosures (1455NHD Series) are effective at dissipating heat from PC boards and other electronic components. Two removable flanges make for easy wall or shelf mounting. They are sized to accept Eurocard PC boards, which can be mounted horizontally by sliding into internal slots built into the body. The two-piece body has a removable belly plate for easy access to the upper volume of the enclosure. 1455NHD1601 and 1455KHD1201 are some examples of this series.

1455HD Series Extruded Aluminum Enclosure

Fans

Hammond's FT Series products are fan trays that are compatible with the standard 19" rack mount. The FT Series can be installed at the rack base to force air across the cabinet, at the top as an exhaust, or below specific equipment parts for spot cooling. FT900TA1BK and FT900HA1BK are some examples from this series.

Air Conditioners

Hammond's DTS Series products are compactly designed 2000-3000 BTU/H indoor air conditioners, designed to be mounted on the side of any enclosure surface. Air circulation is closed loop to prevent mixing with ambient air, as well as intrusion from dust or other particles. DTS3041A115LG and DTS3041A230LG are some examples of this series.

DTS Series Indoor Air Conditioner

Heaters

Hammond's FLHTF Series heaters feature an integrated thermostat and are rated from 125-1300W. They are effective at protecting critical components from the effects of low temperatures, such as condensation and freezing. FLHTF Series heaters are equipped with a temperature limit switch that triggers in the event of fan failure or an overheat condition, cutting power to the heating element. FLHTF800A115 and FLHTF125A230 are some example of this series.

Figure 7: Fan Heater with Thermostat

FLH Series Fan Heater with Thermostat

Breather Kits

Hammond offers a range of breather kits with a minimum cutout diameter of 1.46" and IP45 protection, providing controlled pressure compensation due to temperature variations. An enclosure requiring a breather kit should have two plugs installed in opposite locations. SDA412 and SDV280-1 are some examples of breather kits.

Figure 8: Breather Kit

SDA412 Breather Kit

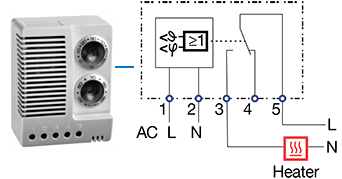

Hygrotherms

The SKTH Series is a range of Humidity and Temperature Control products designed to monitor temperature and humidity in enclosures, and control them by switching resistive and inductive loads (heaters or filter fans). These are well suited for ATMs, parking control gates, ticket dispensers, and traffic control systems where equipment comes into contact with wide-ranging outdoor elements. SKTH012009 and SKTH012009-C are two products of this series.

Humidity and Temperature Control

Summing Up: Climate Control in Electronic Enclosures

Excessive temperatures and humidity within enclosures can drastically affect equipment performance, even potentially damaging circuit components. Climate control systems are effective at maintaining operating temperatures and humidity within an enclosure, and are designed for installation on electronic enclosures, while retaining Ingress Protection ratings. Hammond offers a range of climate control products that enable a suitable operating environment for sensitive electronics.