Take the Poll | Join our Discussion

sponsored by

Overheating in Electronics

One of the major problems with electronics, especially in high-power applications such as industrial automation or robotics, is heat. Not only does heat shorten the life of electronics, overheating can quickly lead to component damage, fire, explosions, or even operator injury. Thermal cutoffs detect abnormal temperatures and are able to shut systems down before any damage occurs. A thermal fuse is a consumable and must be replaced after it blows, whereas a thermal switch resets after it cools down. This Tech Spotlight introduces the thermal switch, ways to implement a thermal cutoff, and some example applications.

What Is a Thermal Switch?

A thermal switch, otherwise known as a thermal reset or thermal cutout, is an electromechanical, temperature-dependent control device that breaks an electrical connection at a specified temperature. Thermal switches are generally reusable and protect against situations that are typically user correctable.

Ways to Implement a Thermal Switch

Thermal switches can be implemented using several technologies, including bimetallic switches, thermal reed switches, mercury switches, rod and tube switches with different temperature coefficients, and gas-actuated switches.

Thermistors and Microcontrollers

A thermistor (a thermal resistor) is a type of resistor that exhibits changes in its electrical resistance in response to changes in temperature. Thermistors are sensitive to temperature fluctuations and can accurately measure temperature. Thermistors are used in applications such as circuit protection (surge protection), temperature measurement of oil, and automotive coolants.

There are two types of thermistors: Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC). An NTC Thermistor decreases its resistance as the temperature increases; conversely, a PTC Thermistor increases resistance with increased temperature.

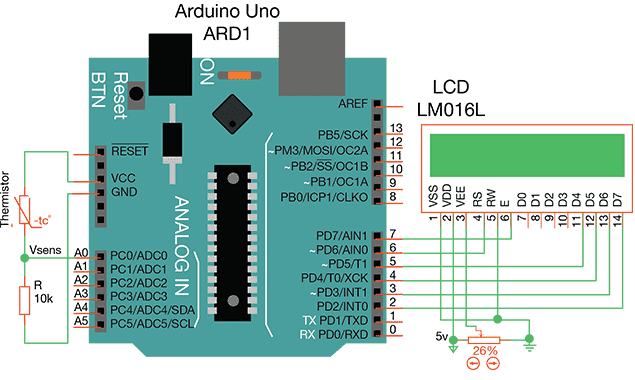

Figure 1: Thermistor and Microcontroller based Thermal Switch

Source: Circuit Digest

Resistance change in a thermistor can be converted into an electrical signal using a Wheatstone bridge or voltage divider circuit. Figure 1 illustrates the implementation of a temperature monitoring circuit using an NTC thermistor connected with an Arduino ATMEGA controller. A voltage divider converts the resistance of the thermistor to an electrical signal (Vsens). When temperature varies, Vsens follows and the changes are read by the microcontroller's analog input and displayed on an LCD screen.

Bimetallic Switches

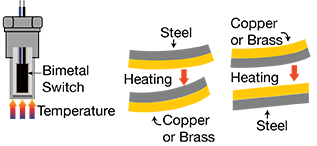

A bimetallic switch consists of two strips of different metals with different thermal properties, bonded together along their length, either joined by rivets or fused. The shape of the structure can be either a flat strip or a concentric coil. As the temperature rises, the two metals expand at different rates, bending the strip. The strip material is generally a combination of brass with steel or copper and steel. The characteristics of a bimetal switch are useful for changeover electrical circuits, or temperature gauges where a pointer indicates the temperature on a dial.

Figure 2: Bimetallic Switch Structure and Operation

Source: EDN

The thermal expansion coefficient of steel is approximately 12 parts per million per degree Celsius, or 12 ppm/°C. The coefficient of copper is 16.6 ppm/°C, and the coefficient of brass is 18.7 ppm/°C. When heat is applied to a strip constructed of steel and copper, or a strip of steel and brass, the strip will bend towards steel, the metal with the lesser coefficient of thermal expansion. Many thermostats detect temperature via bimetallic strips.

Reed Switches

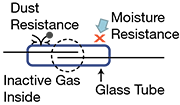

A reed switch is a magnetic reaction-type switch containing two small Fe-Ni alloy plates. As illustrated in Figure 7, reed switches can be encased within a glass tube filled with an inactive gas, reducing the metal fatigue risk of the reed switch and prolonging its life. An encased reed switch is resistant to dust and moisture, as well as being corrosion resistant and explosion proof.

Figure 7: Reed Switch Construction

Source: Kemet

Reed switches open and close in the presence of a magnetic field. For a reed switch to be used as a thermal switch, it must be used in conjunction with a material, such as Thermorite®, that generates a magnetic field based on changes in temperature.

Thermal Switches

Shop our wide variety of Thermorite® Thermal Reed Switches by Kemet.

Don't forget to take our poll.

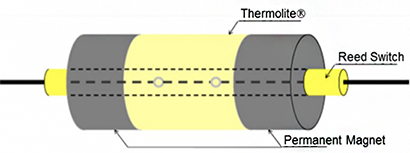

Kemet Thermorite® Thermal Reed Switches

The Curie point, discovered by Pierre Curie, is the temperature at which certain temperature permanent magnets lose their magnetic properties. The engineers at TOKIN, a magnetics-centric company, discovered that adding very controlled amounts of dopants was effective in manipulating a material’s Curie point. This discovery led to the development of Thermorite®, a material that becomes paramagnetic (loses its magnetic property) at very specific temperature points.

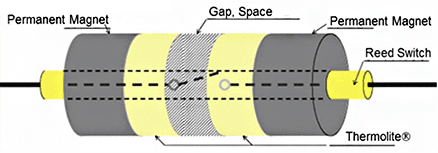

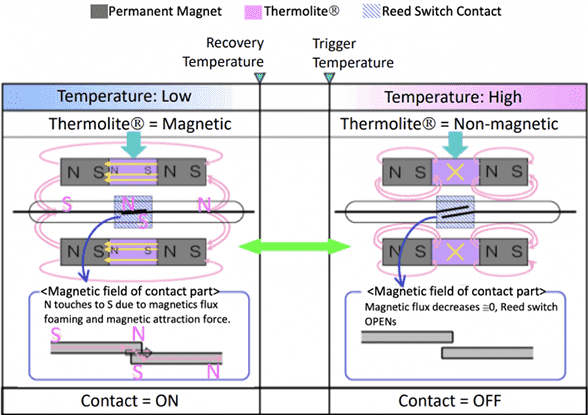

Two types of Thermorite® thermal switches are available: break-type and make-type. Both consist of Thermorite® thermal ferrite, a reed switch, and a permanent magnet. The reed switch is opened or closed based on the changing magnetic properties of the Thermorite® as the temperature changes.

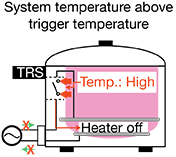

Figure 3 illustrates a break-type switch, a switch that is normally closed. The switch remains closed (ON) if the operating temperature does not exceed a trigger temperature. It opens (OFF) when the temperature increases to a level equal to or higher than the trigger temperature.

Figure 3: Break-type Thermorite Switch

Source: Kemet

Figure 4 illustrates a make-type switch. Make-type switches are open (OFF) when the operating temperature is lower than the trigger temperature. The switch closes (ON) when the operating temperature becomes higher than the Trigger temperature.

Figure 4: Make-type Thermorite Switch

Source: Kemet

Break-type Switch Operation

Figure 5 illustrates the operation mechanism of a break-type switch. An annular magnetic field is generated by the Thermorite® at temperatures lower than the Curie temperature. This magnetic field induces N and S polarity in the contacts within the reed switch, and creates a magnetic attraction force that makes the tips of the contacts touch, putting the switch into the closed or ON state. When the temperature of the Thermorite® reaches the Curie temperature, the Thermorite® loses its magnetic flux and becomes non-magnetic. Because the magnetic attraction force is no longer present, the tips of the contacts open, putting the switch into the OFF state.

Figure 5: Break-type Switch Operation

Source: Kemet

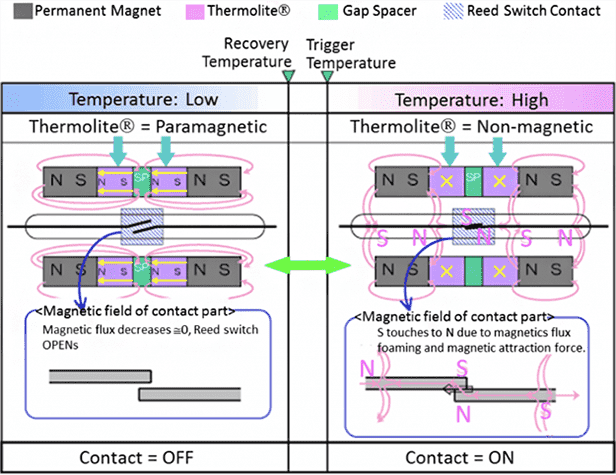

Make-type Switch Operation

The difference between a make-type and a break-type switch is the addition of a Gap Spacer between two sections of Thermorite®. If the temperature does not exceed the trigger temperature, the Thermorite® generates a magnetic field that separates the contacts in the reed switch. When the temperature reaches the trigger point, the Thermorite® becomes non-magnetic. N and S polarity is induced in the contacts of the reed switch by the permanent magnets, creating a magnetic attraction force that causes the tips of the contacts to touch, closing the switch (ON).

Figure 6 illustrates the operation mechanism of a make-type sensor.

Figure 6: Make-type Switch Operation

Source: Kemet

Thermorite® thermal switches simplify the design of control systems and are more cost-effective than their thermistor and microcontroller-based counterparts, which depend on several additional components, including A/D converters, FETs, or relays. Thermorite® thermal switches offer greater accuracy and overall robustness, in addition to having superior response time and relatively low hysteresis, when compared to bimetallic switches. Additionally, bimetallic switches can potentially suffer mechanical fatigue and failure over time.

The TRS series and OHD series from Kemet are Thermorite®-based thermal reed switches. They are a low-cost thermal switch solution that can be used in applications where ON or OFF switching via trigger temperature is required.

TRS Series Thermal Reed Switches

The TRS series of thermal reed switches is a reliable, precise, and highly responsive family of temperature-sensitive switches. The TRS series is dust, explosion, and corrosion-proof. It covers an extensive temperature range of −10°C to +130°C, with a temperature accuracy of ±2.5°C. The simple circuit design conserves energy and ensures long operational life. The TRS series is available in a variety of package types. OHD1-55M , TRS1-100BPR002 and M-TRS5-0B are some examples from this series.

Figure 8: Different package types of TRS series switches

The TRS-P1 and TRS-P2 Type switches feature a screw mount form factor, simplifying integration for many applications.

TRS1-110MPR001 and TRS1-95MPR002 Thermal Switches

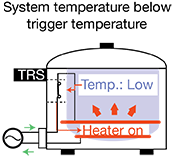

As illustrated in Figure 9, the TRS series thermal switch can be used as an effective heater control in a rice cooker. The reed switch is closed below a specific trigger temperature, feeding power to the system and keeping the heater warm. When the operating temperature reaches the trigger temperature, the Thermorite® in the reed switch loses its magnetic property. The reed switch opens, turning off the heater and avoiding excessive heat in the system.

Figure 9: TRS Switch used in Rice Cooker

Source: Kemet

OHD Series Thermal Guards

The OHD series Thermal Guard is a Thermorite®-based reed switch used for thermal problem countermeasures and safety standard conformity. The OHD Series has a wide range of operating temperatures in 5°C increments, from +30°C to +130°C. They are compatible with extremely low (0.1 mW or lower) to high power (6 W) signals. The OHD series switches have strong environmental durability and are dust, explosion, and corrosion-proof. OHD3-60B and OHD1-50B are some examples from this series.

OHD Series Thermal Guard (OHD3-60B)

Summing Up Thermal Switches

Thermal switches play a critical role in temperature monitoring, and they also serve to shut down systems that are overheating. Excess heat poses a serious threat to the longevity of electronic components, and if left unchecked, it has the potential to cause damage or injury to operators. Thermal switches are used to safely shut down systems when their operating temperature exceeds a safe level. Among the various methods of implementing thermal switches, Thermorite®-based thermal reed switches are a simple, cost-effective, and reliable solution.