How do you Feed the World?

Agriculture is perhaps the most important industry on the planet, and with a population predicted to grow to 9.8 billion by 2050, maintaining the food supply is even more crucial. There have always been challenges, however; farming is highly dependent on environmental conditions, and pestilence can destroy entire crops. Sustainability is also a key issue driving improvements in efficiency in the various food production processes. With available farming land shrinking around the world, farmers have fewer resources with which to feed the world.

Figure 1: Smart greenhouse

Source: Bridgetek

Introducing the Smart Farm

Advancements in technology have streamlined R&D and manufacturing for almost every industry, and agriculture is no different. Agriculture 4.0, or smart or digital farming, makes use of Internet of Things (IoT) technology, which features capabilities such as 24/7 monitoring with smart sensors and using machine learning (ML) to predict field performance based on sensor data history. With smart farming technology, farmers won’t need to water every field uniformly, just the parts that need it. Speed, efficiency, and success rates increase, while costs for materials, consumables, and maintenance go down.

Sensors in Farming

A variety of sensors can be used to gather measurements that paint an accurate picture of environmental conditions, including soil chemistry, air quality, water chemistry, weather, and light. These measurements are sent back to a controller, which can activate devices such as automated sunshades or irrigation systems. Measurements can also trigger alerts on a central dashboard, in case human intervention is needed.

Temperature and humidity sensors monitor the agricultural planting environment, whether it is outdoors or in a greenhouse. Temperature sensors can also monitor the heat generated by machinery, enabling predictive maintenance.

Soil moisture sensors measure the amount of moisture in the soil, so it can be kept at a suitable level. Soil moisture sensors typically determine moisture by measuring the dielectric constant of the soil.

The pH of the soil is an important factor; one plant might require more acidity, while another might flourish only under basic conditions. The pH of soil can change due to environmental conditions. A soil pH sensor uses the current generated by an oxidation-reduction reaction to determine the pH.

Sufficient light may be the most important condition when farming. Plants produce food through photosynthesis, using light to create glucose. Light sensors monitor the amount of light present, enabling a controller to adjust light levels. On cloudy days, LED grow lamps on a greenhouse can be turned on to compensate. On days that are too bright, sunshades can be automatically lowered.

Figure 2: CO2 Sensor

CO2 is another ingredient in photosynthesis; typically a greater amount of CO2 enhances the growing process. CO2 sensors work in various ways. An IR sensor detects the amount of CO2 present based on the absorption of infrared light at a specific wavelength. An electrochemical sensor measures the electric charge generated by a chemical reaction.

Electrical Conductivity (EC) and Dissolved Oxygen (DO) sensors help to measure the chemistry in a water tank, while Level sensors measure the amount of water present.

Other sensors helping to increase efficiency in agriculture include GPS sensors, used for keeping track of livestock, smart cameras, utilized for tasks such as detecting weeds or pests, and accelerometers/motion sensors, which can detect movement from humans and animals, as well as vibration inconsistencies in machinery.

Data Analytics

The vast amount of data generated by the sensors can be analyzed to not only alert farmers of problems, but also to predict them. Machine learning (ML) is a subset of artificial intelligence (AI) where software algorithms analyze large datasets in an effort to detect patterns that might allow them to predict outcomes. In agriculture, ML can be used in conjunction with soil chemistry sensors to detect the early presence of diseases and pests in plants.

Infrastructure

The biggest strength that Agriculture 4.0 brings is connectivity. Smart sensors, AI, and predictive maintenance have brought significant improvement to agricultural and industrial processes, but the functionality that ties everything together is the ability to remotely collect and exchange data. This connectivity must be able to cover large distances, such as the size of an industrial farm. Without reliable connectivity over distance, 24/7 monitoring would not be possible.

To gain widespread adoption, the infrastructure needs to be cost-effective and easy to install, ideally, plug-and-play. Farm personnel may be accustomed to traditional processes, so the set-up and user interface of an IoT solution must be intuitive. There should also be resources to provide power to the sensors and other devices in the field, minimizing connections and/or the use of batteries. To support changing conditions and seasons, the system should be flexible and reconfigurable, as well as scalable. Additionally, the system should be rugged enough to handle harsh outdoor conditions.

Because the size of the data being sent isn’t enormous, speed is not as big of a factor as is reliability. Fortunately, there are industry standard data transmission technologies, such as Ethernet, that are cost-effective and reliable.

Internet of Things

Shop our wide variety of MCUs and IoT products from Bridgetek.

Don't forget to take our poll.

Bridgetek LDSBus and the IOTPortal

Bridgetek’s Long Distance Sensor Bus (LDSBus) addresses the challenges of Agriculture 4.0. At its core, the LDSBus is a serial data bus that supports distances of up to 200m. The LDSBus is able to supply 24V of power, so batteries or building a separate infrastructure for power is unnecessary. Bridgetek also offers a range of LDSBus-compatible sensors and actuator devices for easy integration. The bus operates at a 230kbps data rate, providing sufficient bandwidth to control up to 127 devices on the bus.

Bridgetek offers a growing line of LDSBus-compatible sensors, many of which are suited to agricultural applications. Sensors include the 4-in-1 (temperature, humidity, motion detection, and ambient light measurement), pH Sensor, EC (electrical conductivity), DO (dissolved oxygen), and thermocouple sensor. To control other equipment, Bridgetek offers the 2CH Relay, a relay that can handle loads of up to 16A, supporting both AC and DC loads. The 2CH Relay + iSENSE adds current sensors, which can monitor currents of up to 20A.

The central hub for all of the devices on the LDSBus is Bridgetek’s IOTPortal Gateway. The IOTPortal enables LDSBus devices to communicate with Bridgetek’s IoTPortal Cloud without needing a PC. The IoTPortal Cloud lets users configure, control, and monitor every device connected to an LDSBus system, without writing a single line of code. A system built around the IoTPortal Gateway is highly scalable, supporting up to 320 sensors/actuators (with the option of adding more Gateways for more devices), and can cover an area of 12.6 hectares (or 12 football fields). The IoTPortal Cloud enables wireless devices, such as smartphones and tablets, to control and monitor the devices on an LDSBus system.

Modern Agriculture with the IoTPortal

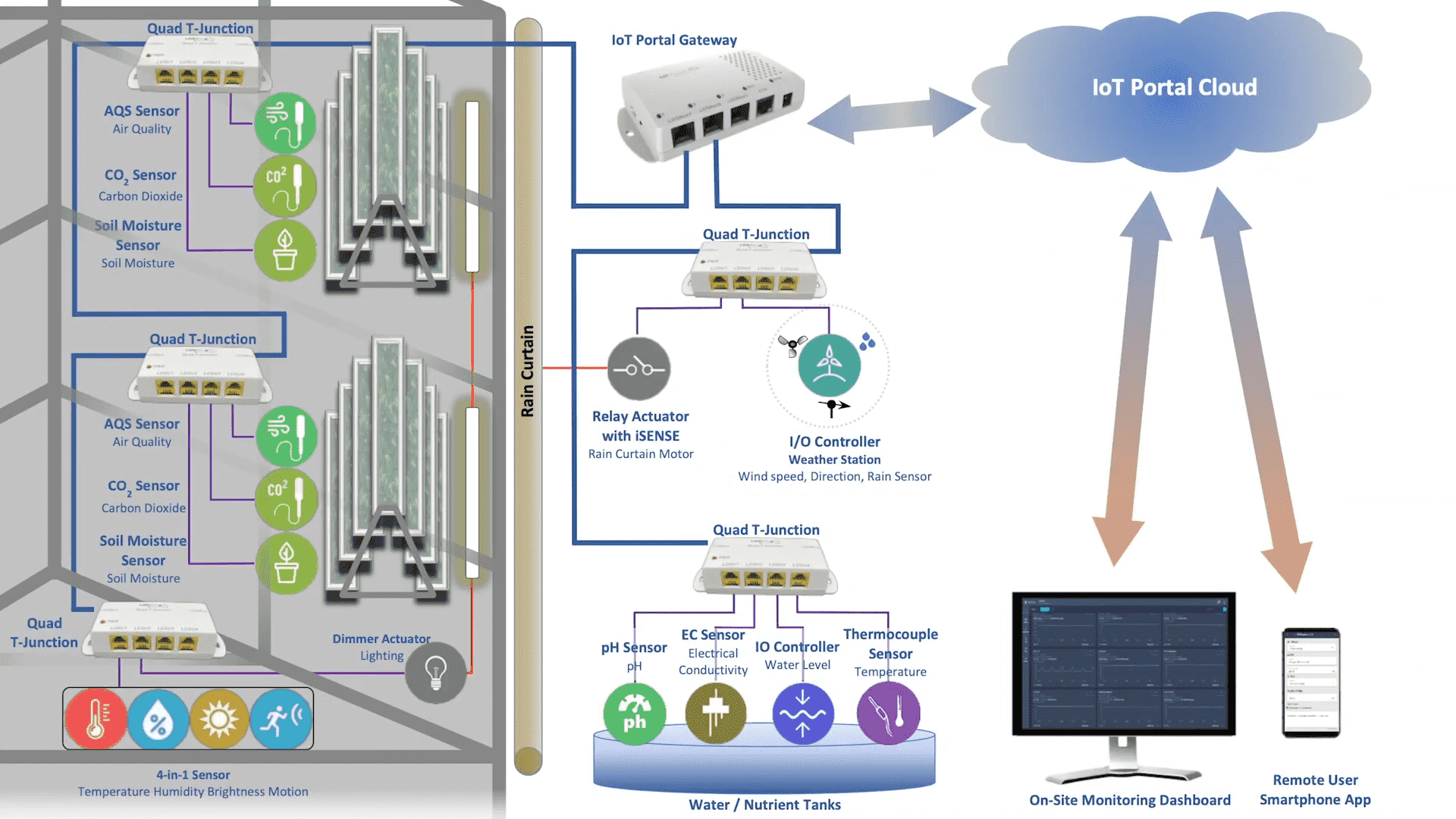

Figure 3 depicts the block diagram for a smart greenhouse with an LDSBus and IoTPortal infrastructure.

Figure 3: Smart Greenhouse with LDSBus infrastructure

A variety of Bridgetek LDSBus sensors monitor almost every aspect of the environment in the greenhouse. Air quality and CO2 sensors measure the quality of the air. Soil moisture sensors detect the amount of moisture in the soil, and can be set to automatically irrigate the plants if moisture levels fall below a certain level. The 4-in-1 sensor measures temperature and humidity, as well as ambient light levels.

Figure 4: 4-in-1 Sensor

If light levels are low, LED lamps are automatically turned on. The 4-in-1 sensor also measures motion, automatically turning on lights when people are near.

Figure 5: Trailing Edge Light Dimmer

A weather station connected to an I/O controller detects wind speed, direction, and rain. If rain is detected, the Relay Actuator automatically activates the rain curtain motor to block the rain. Several sensors monitor the Water/Nutrient Tanks, measuring water level, pH, and temperature.

Every device is connected to an IoTPortal gateway, which connects to the IoTPortal Cloud. Devices such as a smart phone, tablet, or PC can connect to the IoTPortal Cloud, enabling personnel to configure, control, and monitor every device. This entire system can be configured and deployed without the need for custom code or software.

Summing Up: Making the Connections for Digital Farming

in partnership with

The rise of the Internet of Things has brought about improvements in a myriad of industries, including farming, with Agriculture 4.0. Farming processes are made more efficient and automated with the addition of sensors and actuators, and artificial intelligence to analyze the data. With so much data moving around at all times, the crucial factor of a smart farm is connectivity. Agriculture 4.0 requires farms to have a reliable data and power infrastructure that covers large distances. Bridgetek’s Long Distance Sensor Bus (LDSU) fits the requirements for smart farming, featuring not only data and power transfer for large areas, but a portfolio of sensors and actuators that can all be controlled out of the box via Bridgetek’s IoTPortal Cloud.

-

dougw

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

dougw

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children