Reducing Power Consumption in Battery-powered Devices

Many devices in IoT-based systems are designed with a small form factor and are battery powered. Battery replacement in a commercial infrastructure usually involves the dismantling and refitting of electronic components, including the sensors that form the backbone of Internet of Things (IoT) technology. Such efforts consume a substantial amount of time and manpower, as a commercial building network may contain thousands of these devices. This makes energy-efficient, battery-powered, portable sensors and actuators the most acceptable solution for retrofitting operations. Increasing the battery life of these sensors improves system reliability by reducing the downtime caused by a single node running out of battery. This article discusses the energy consumption challenges that IoT devices face and possible solutions, including the use of ultra-low power sensors.

Energy Usage in Wireless Sensors

With the rise of IoT, embedded designers are more than ever focusing their attention and efforts on system energy usage. One example of a purpose-built product in this regard is a battery-powered wireless sensor node. The operation of a wireless sensor comprises a series of events, with each event requiring a certain amount of power. These events include:

- Waking up, measuring the relevant parameters, and processing the data into messages

- Powering up the radio frequency amplifier, transmitting the messages, and powering down the radio frequency power amplifier

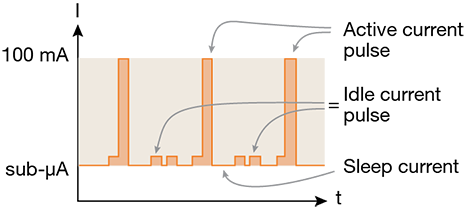

These activities are responsible for high battery power consumption and discharge. Figure 1 illustrates current consumption in a battery-powered wireless sensor during its three main states: active, idle, and sleep.

Figure 1: Power consumption in battery-powered sensors during their three main states

Source: eenewsanalog.com

There are multiple techniques and design strategies designed to decrease power consumption and optimize power-saving performance: hardware or software energy optimization, network optimization, and energy harvesting.

Hardware Optimization

Design engineers can choose microcontroller units (MCUs) that are designed specifically for low-energy consumption. An MCU, however, isn’t the only potential energy hog in an IoT device. Opting for low-power sensors and nodes can also substantially reduce power consumption.

Network Optimization

Choosing a connectivity solution for any IoT device depends heavily on the application’s chosen components, the performance of the connected objects, and their energy consumption. IoT applications with low power requirements can make use of Low Power Wide Area Network (LPWAN) for long-distance connectivity, while battery-powered IoT devices can use Bluetooth Low Energy (BLE) for short to-medium communication ranges. The distance between two nodes, system topology, data rate, and the message size are all factors that influence the transmission time, which in turn impacts power consumption.

Optimizing Software for Low Power Consumption

Programming the device to run in low power modes, rather than active modes, will make a significant difference in conserving battery power. New developments in low power management have introduced a wide range of ultra-low-power sleep modes. Whereas previous devices have only differentiated between run and idle modes, current devices feature more levels of granularity, including standby, doze, sleep, and deep sleep. Applications are programmed to spend as little time as possible in the MCU’s active mode. This might mean simplifying calculations, batching operations, or transitioning to an asynchronous and interrupt-driven design.

Applications

Weather Station Solution

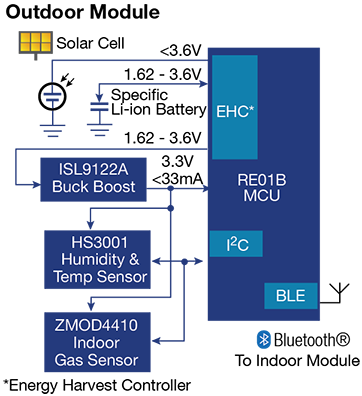

Figure 2: IoT-based Indoor Air Quality measurement

Source: Renesas

This weather station solution supports smart home and agriculture systems where an indoor controller unit aggregates weather data (temperature, humidity, and CO2 concentration). The weather data is measured by an outdoor unit that is solar powered and features an ultra-low-power MCU. The indoor and outdoor units are connected via BLE, and captured data is communicated to the Cloud via Wi-Fi. Renesas’ ZMOD Digital Gas Sensor family uses embedded artificial intelligence (AI) technology and leverages different Operating Modes, which use time, temperature, and gas signatures that enable unique signals from a highly trained machine learning (ML) system. The outdoor unit is controlled by an ultra-low power RE01 MCU. The indoor unit is controlled by an RX-based 32-bit MCU with added security features that make it suitable for cloud communication.

IoT Cold Chain Monitoring

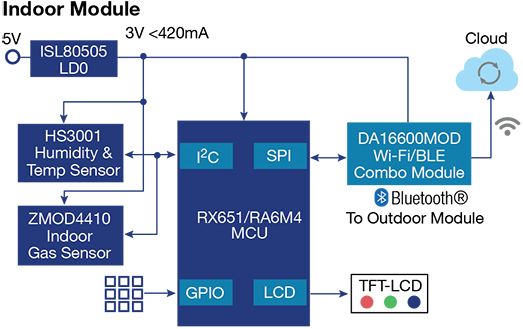

Figure 3: IoT-based Cold Chain Monitoring

Many industries, including agriculture, pharmaceuticals, and logistics require refrigerated storage for their products and ingredients. An IoT-based cold chain monitoring solution allows temperature and humidity to be measured from a remote location, with alerts set up for temperature changes and anomalies, preventing waste and spoilage as ingredients move through the supply chain. The system is controlled by a Renesas RA4W1 32-bit MCU, using Bluetooth LE 5.0 for wireless communications. Sensors include the ZMOD4410 indoor air quality sensor and the HS3001 temperature and humidity sensor.

Low-power Sensors from Renesas

ZMOD4410 Indoor Air Quality Sensor

The ZMOD4410 gas sensor module is designed to detect total volatile organic compounds (TVOCs), estimate CO2, and monitor indoor air quality. The sensor communicates via its built-in I2C interface. To reduce power, gas sensors can be operated in various modes, such as continuous temperature operation or duty cycling. The ZMOD4410 Indoor Air Quality Sensor offers two power modes: Continuous and Low Power. When “Continuous” is selected, the measurement is performed continuously. When “Low Power” is selected, measurements are taken in intervals of 5475 ms. The average power consumption in Low Power mode is 0.16mW.

ZMOD4510 Outdoor Air Quality Platform

The ZMOD4510 Outdoor Air Quality (OAQ) Platform is a gas sensor system that can be used in a variety of indoor and outdoor applications. The ZMOD4510 uses machine learning and traditional methods to determine Air Quality Index (AQI), which is based on concentrations of gases in the atmosphere, including nitrogen dioxide (NO). The ZMOD4510 currently has two released operation modes.

| Air Quality Index (AQI) | Level of Concern and Air Quality Condition | O3 Concentration 1h average [ppb][a] | O3 Concentration 8h average [ppb] | NO2 Concentration 1h average [ppb] | Color Code |

|---|---|---|---|---|---|

| 0 to 50 | Good | 0 to 62 | 0 to 54 | 0 to 53 | Green |

| 51 to 100 | Moderate | 63 to 124 | 55 to 70 | 54 to 100 | Yellow |

| 101 to 150 | Unhealthy for Sensitive Groups | 125 to 164 | 71 to 85 | 101 to 360 | Orange |

| 151 to 200 | Unhealthy | 165 to 204 | 86 to 105 | 361 to 649 | Red |

| 201 to 300 | Very Unhealthy | 205 to 404 | 106 to 200 | 650 to 1249 | Purple |

| 301 to 500 | Hazardous | 405 to 604 | - | 1250 to 2049 | Maroon |

Table 1: Air Quality Index Levels Described by the EPA

Operation Mode 1 allows a general measurement of Air Quality (AQ), including the non-selective measurement of NO2 and O3. The AQI is determined based on the classifications by the EPA (Environmental Protection Agency) for O3 and NO2 levels (Table 1).

Operation Mode 2 allows the selective measurement of O3 with a fast sample rate of two seconds. With an average consumption of 0.2mW, power consumption is minimal. The second-generation OAQ algorithm is specifically designed to detect ozone, and the cross-sensitivity response to NO2 is reported as less than 25 AQI, even at NO2 levels up to 200ppb.

| Symbol | Parameter | Conditions | Min | Typical | Max | Unit |

|---|---|---|---|---|---|---|

| Average Power: OAQ 1st Gen | Outdoor Air Quality | ---- | 21 | ---- | mW | |

| Average Power: OAQ 2nd Gen | Selective ozone with ultra-low power | ---- | 0.2 | ---- | mW | |

| IACTIVE | Supply Current, Active Mode including Heater Current for OAQ 1st Gen | At VDD = 1.8 V | ---- | 11 | 13 | mA |

| At VDD = 3.3 V | ---- | 08 | 10 | mA | ||

| IACTIVE | Supply Current, Active Mode including Heater Current for OAQ 2nd Gen | At VDD = 1.8 V | ---- | 10 | 12 | mA |

| At VDD = 3.3 V | ---- | 6 | 8 | mA | ||

| ISLEEP | Current during measurement delays | Sleep Mode ASIC | ---- | 450 | ---- | mA |

Table 2: Gas Sensor Module Specifications during Operation

HS3001 Humidity and Temperature Sensor

Renesas’ HS3001 sensor is a MEMS-based relative humidity and temperature sensor. It features fast measurement response time (typically 6 seconds) with high accuracy. The HS300x is factory-programmed to operate in Sleep Mode. In Sleep Mode, the sensor waits for commands from the controller before taking any measurements. The digital core only performs conversions when it receives a measurement request command (MR); otherwise, it remains powered down. It consumes a minimal amount of power: an average of 1.0µA with one RH+T measurement per second, 8-bit resolution, and a 1.8V supply. Its low power consumption, along with its small form factor (3.0 x 2.4 x 0.8 mm), make it well suited for use in portable, battery-operated devices.

Summing up: Low Power Sensors for IoT

in partnership with

Power consumption plays an important role in IoT devices and nearly all embedded devices. Choosing components capable of running at reduced power, including MCUs, power sources, communication protocols, and sensors, diminishes power consumption concerns. Sensors are the primary element of any IoT-based system and should ideally consume minimal power without compromising their static and dynamic characteristics. Renesas offers a variety of sensors that are designed for use in IoT systems and feature low power operation modes that greatly extend the life of battery-powered devices.

-

dougw

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

dougw

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children