Take the Poll | Join our Discussion

sponsored by

Introduction

5G signals are transmitted using ultra-high frequencies, as high as 39GHz or more. In contrast, 4G uses 700 MHz to 2500 MHz to transfer data. Such high frequencies make 5G vulnerable to electromagnetic interference (EMI). EMI increases the noise in a system, reducing signal quality, potentially culminating in a communication error. EMI can affect electronic systems without contact; many devices generate electric fields that affect other devices. Several techniques exist for reducing EMI, including shielding and filtering. For compact devices, such as smart phones or tablets, noise suppression sheets offer a thin, flexible, and easy to install alternative to metal enclosures.

What is EMI, where does it come from, and what causes it?

EMI is unwanted signal, in the form of noise, generated by either electromagnetic induction or the electrostatic coupling of electronic devices. The noise can be continuous (in the form of a constant background presence) or occurring randomly. Electronic switching elements are a common source of EMI, the effects of which can cause undesirable system operations.

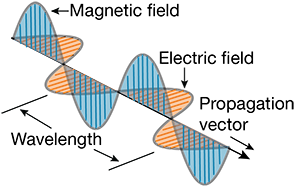

EMI occurs in a wide range of spectrums, including radio wave and microwave frequencies. It consists of electromagnetic (EM) waves, which have both electric (E) and magnetic (H) field components oscillating at a mutual 90° angle, as illustrated in Figure 1.

Figure 1: Representation of an Electromagnetic Wave

Source: Prado-Gonjal, Jesús. (2014). Microwave-assisted synthesis and characterization of inorganic materials. 10.13140/2.1.1646.1766.

Types of EMI

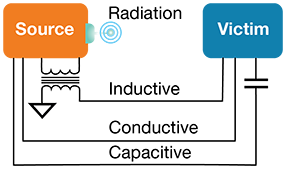

EMI signals can enter a system in two ways: radiation or conduction. Radiated EMI does not need physical contact to affect the system – it travels through the air. Radiated EMI occurs when a device produces an electrical field that spreads outwards. This field can be blocked using shielded enclosures, cables, and connectors. Any unshielded part of the system can potentially leak radiated EMI. Radiated EMI can be narrowband or broadband. Narrowband EMI only affects a specific radio frequency; one example is EMI generated by a radio transmitter. Broadband EMI affects a larger portion of the radio spectrum, and is often caused by malfunctioning equipment.

Conducted EMI occurs when unwanted signals in a circuit pass from one position to another along a conductor (such as wire or PCB trace). The signals can interfere with the operation of the destination circuit or device, causing noise or other artifacts. One example of conducted EMI is an incoming power line, which can contain noise and other anomalies, in addition to the AC voltage signal. Most AC power systems contain line filters and other circuitry in order to eliminate interference on incoming power lines.

Figure 2 illustrates possible coupling mechanisms for EMI.

Figure 2: Coupling Mechanisms for EMI Attack

Source: Richelli A, Colalongo L, Kovacs-Vajna Z. Electronics. 2020

How does EMI affect electrical systems?

Managing EMI is a recurring challenge in modern systems, where circuit components are tightly packed. The effects of EMI range from a minor deterioration of signal quality to equipment malfunction. Three common EMI problems are radio frequency interference, electrostatic discharge, and power disturbances.

De-sense is the degradation in sensitivity due to unwanted noise. In any wireless receiver, there exists a noise floor, the sum of all unwanted noise in the system. A certain amount of background noise is always present; however, the presence of EMI increases noise, sometimes significantly, reducing signal-to-noise ratio and resulting in degraded performance. In wireless products, the RF de-sense problem becomes severe due to the increasing data rate and routing density of PCBs. De-sense mitigation is a necessity for modern devices. The key to de-sense reduction is discovering the source of the noise energy, and removing or blocking it.

How do you reduce EMI?

Grounding, bonding, filtering, isolating, and shielding are some of the strategies used to solve EMI-related issues.

Shielding

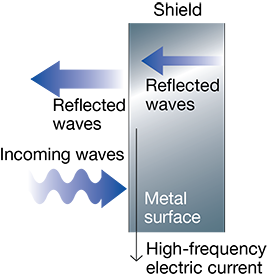

The purpose of an EMI shield is to block interference from a particular device or zone. Such protection is possible through the effective placement of shielding materials, which reduce the EM energy radiated by electronic equipment. The unit for measuring the effectiveness of EMI shielding is decibels (dB).

Figure 3 illustrates the way a shield works. EMI shields use conducive barriers that isolate sensitive electronic equipment from unwanted electrical noise. In cases of improperly implemented grounding, high-frequency current can flow over metal surfaces, with noise being reflected at metal openings, shielding joints, and other parts.

Figure 3: The Process of Shielding

Source: KEMET Electronics

Enclosure design and shielding material have a great effect on the effectiveness of EMI shielding. The telecommunications industry uses various EMI shielding materials, including plastic, conductive silicone, metal shields, conductive fabric gaskets, and wave absorbing devices.

EMI Filter

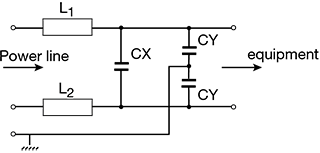

The typical EMI/EMC filter often comprises a network of passive electronic components, which include capacitors and inductors (called an LC circuit). Many filters also contain active components, such as op amps. An EMI filter works by selectively blocking or shunting the unwanted frequencies. AC line filters are usually dual-stage, having integrated differential mode and common mode filtering. Capacitors can be used to bypass and decouple circuits. Additionally, 50 Hz or 60 Hz hum from power lines can be eliminated using notch filters.

Figure 4: EMI Filter Circuit

Source: KEMET Electronics

Figure 4 depicts an EMI filter designed using film capacitors CX and CY, and shows the waveform before and after filtering.

Noise Suppression Sheets

Noise suppression sheets are flexible sheets that are constructed of magnetic shielding material. They can be pasted onto sources of noise emission, or on areas that are vulnerable to noise radiation. They are easy to cut or punch into specific shapes and because they are flexible, they can be used on curved surfaces and cables. They are generally easy to install, and noise reduction sheets with an adhesive backing can be installed like stickers.

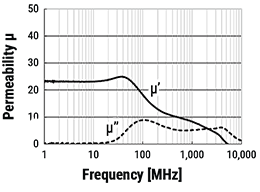

One important specification for noise reduction sheets is permeability. The more permeable a substance is, the more electromagnetic waves it can absorb. A material with high permeability can have high noise reduction capabilities, even if it is very thin.

KEMET Electronics Flex Suppressor

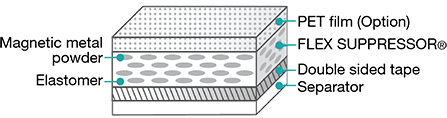

The Flex Suppressor from KEMET Electronics is a noise suppression sheet that reduces EMI by absorbing radiated noise and converting it into negligible amounts of heat. Figure 4 illustrates the construction of the Flex Suppressor, essentially a composite magnetic sheet, created by the blending and mixing of micron-sized, magnetic powders into a polymer base. Its unique structure allows the Flex Suppressor to reduce noise better than ferrite-based devices. The Flex Suppressor is thin and flexible (0.1mm to 1mm thickness), and comes with an adhesive backing.

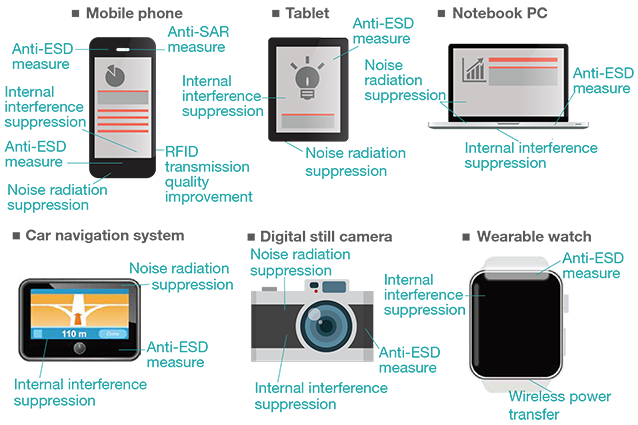

The thinness and flexibility of noise reduction sheets make them an effective solution for noise reduction in modern devices such as smart phones and tablets, which are becoming increasingly thin and compact.

Figure 4: Composition of Flex Suppressor

Buy Now

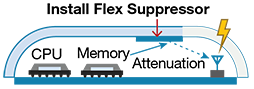

The Flex Suppressor is designed for EMI noise mitigation and reducing de-sense caused by radiated emissions in RF circuits. It effectively reduces wide-band high frequency EMC. The Flex Suppressor can improve wireless power transfer, in addition to near-field communication (NFC) signals such as RFID. AEC-Q200 qualified products are also available.

Figure 5: Installation of Flex Suppressor

Source: KEMET Electronics

| Features | GHz Band High Performance Type | ||

|---|---|---|---|

| Series | |||

| Effective Frequency | |||

| Operating Temperature (°C) | |||

| Thickness (mm) | |||

| Standard Dimensions (mm) | (Roll on request) |

||

| Permeability (μ) |  |

|

|

Table 1 illustrates various specifications of the FG1, EFG2, and EFG2 series of Flex Suppressor, including their permeability characteristics.

Flex Suppressor for 5G Frequencies

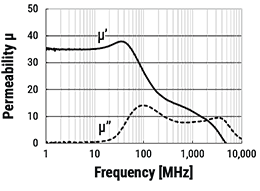

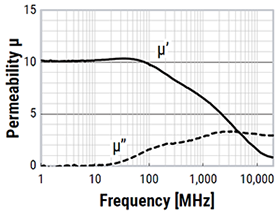

The FS and EFS series of Flex Suppressors operate in a broader frequency range (up to 40GHz band), making them suitable for 5G-connected devices for commercial, telecommunications, and automotive applications.

Table 2 shows the relevant specifications of the FS and EFS series Flex Suppressors, along with their notable permeability features.

| Features | Super High Frequency Type | |

|---|---|---|

| Series | ||

| Effective Frequency | ||

| Operating Temperature (°C) | ||

| Thickness (mm) | 0.03/0.05/0.075/0.1 | 0.1/0.2/0.3/0.5/1.0 |

| Standard Dimensions (mm) | (Roll on request) |

|

| Permeability (μ) |  |

|

The products in KEMET’s Flex Suppressor line are available with a variety of specifications, satisfying a wide range of design needs. Flex Suppressors are well-suited for use in portable equipment, where size and form factor is an important consideration.

Figure 6: Flex suppressor wide application range

Source: KEMET Electronics

Flex Suppressor

Shop our wide variety of Flex Suppressors by KEMET Electronics.

Don't forget to take our poll.

Improvements in LTE, Wi-Fi, and GPS technology have led to new generations of wireless devices, many of which are thin, offering scant space for additional components.

KEMET’s FX5 and EFX6 are highly permeable and suitable for space-constrained thin devices. The FG1 and EFG2 series Flex Suppressor perform well in the GHz band and are suitable for improving Wi-Fi receiving sensitivity. The FF1 and EFF4 are geared towards in-vehicle devices and conform to AEC-Q200 standards. They offer specifications such as high-temperature resistance and UL94V–O approved flame resistance.

Reel-type Flex Suppressors can be wound on cables, effectively suppressing cable-generated radiated noise. One example is the charger cable of a smartwatch, which can use a strip of Flex Suppressor to reduce the noise that would normally radiate from the cable.

Conclusion

In today’s wireless world, the dangers posed by EMI are ever increasing. Several techniques exist for effective EMI reduction, including shielding and filters. Because of their thinness and flexibility, noise suppression sheets enable designers to add shielding to devices with small and unusual form factors, by simply pressing it on like a sticker. Flex Suppressor noise suppression sheets from KEMET Electronics are capable of attenuating noise signals in various frequency bands from 1 MHz to as high as 40 GHz. They are suitable for shielding EMI in applications ranging from consumer electronics and automotive infotainment, to super-high frequency (SHF) applications, such as equipment supporting the 5G infrastructure.