A look at different types of shielding used in cables to block noise, crosstalk, and EMI.

sponsored by

How do you protect a cable from unwanted signals?

Industrial environments are often plagued with electrical noise and electromagnetic interference (EMI). The presence of EMI can cause electromagnetic induction and electrostatic coupling or conduction, which can lead to several anomalies, including noise and even system damage. Although insulation protects a cable from mechanical (scratches, abrasion) and environmental (moisture, spills) degradation, it is ineffective against electromagnetic energy. To reduce the effects of electromagnetic radiation, cables must be properly shielded. This article explains the different types of cable shielding and their effectiveness.

What is a shielded cable?

A shielded cable is a cable with one or more conductors enclosed by a standard conductive layer, which shields the conductors from electromagnetic energy. The shield functions as a Faraday cage, blocking electromagnetic fields, reducing the electrical noise that they generate. Shielding also reduces electromagnetic radiation that may interfere with other devices.

Effects of EMI on Cables

The effects of EMI range from near imperceptible to catastrophic, which can result in equipment malfunction. Cables can be the primary source of transfer for EMI, as well as being a source and receiver. As a source, a cable can either conduct noise to other equipment or function as an antenna that radiates noise. As a receiver, the cable can pick up EMI radiated from other sources. There are four key areas of signal interference that are remedied by shielding:

- Conducted EMI - Noise signals are transmitted through electrical conduction paths, such as cables and ground planes. Crosstalk occurs when cables pick up signal radiated from adjacent cables.

- Radiated EMI - Electric and magnetic fields can be transmitted from a source to receptor just by radiating through the air, without contact. Typical sources of radiation include motors, generators, and transformers.

- Electrostatic Discharge (ESD) – The most common cause of ESD is the contact and separation of two electrically charged materials, resulting in the sudden flow of current between them. An ESD event begins with a gradual accumulation of energy, followed by a quick breakdown. This rapid breakdown can cause EMI problems in electronic systems. The energy discharge produces EMI frequencies in the hundreds of megahertz, causing issues via electromagnetic coupling.

- Radio Frequency Interference (RFI) – RFI is unwanted electrical noise or radio frequency energy caused by an external source that influences a circuit via electromagnetic induction, conduction, or electrostatic coupling.

Table 1 lists some typical sources of noise. It's important to note that switching heavy loads, inductive heaters, and large transformers can generate a high amount of EMI, both conducted and radiated.

| Noise Level | Noise Source | Typical Locations |

|---|---|---|

| High | Electrolytic processes, heavy motors, generators, transformers, induction heating, relay controls, power lines, and control wire in close proximity | Heavy processing and manufacturing plants like steel mills and foundries |

| Medium | Wiring near medium-sized motors, control relays | Small manufacturing units |

| Low | Wiring distant from power lines, motors; motors less than 5hp; no induction heating, arcs, control, or power relays nearby | Storage places, light assembly operations, labs, and offices |

Table 1: Areas of Noise Level in Industry

In an unshielded cable, the conductor is encased only by an insulated plastic jacket. In a shielded cable, an outer shield acts as a barrier that separates the electric field surrounding the central conductor from the external environment. For the barrier to be effective, the shielding material must be highly conductive.

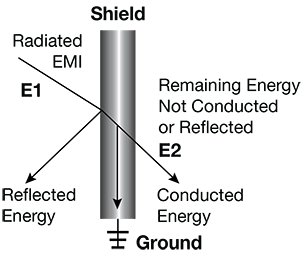

Figure 1: Basic principle of shielding

Source: Belden/Alpha Wire

Construction of shielding cable

The shield can reduce EMI in two ways (Figure 1), either by reflecting the radiated energy, or conducting the radiated energy to ground. In both instances, the conductors are protected from EMI. In many cases, some energy can pass through the shield, but at a highly attenuated level. A material’s shielding effectiveness (SE) is the ratio of the RF energy on one side of the shield (E1) to the RF energy on the other side (E2). SE is expressed in decibels (dB).

Shielding Effectiveness (dB) = 20 log10E1/ E2

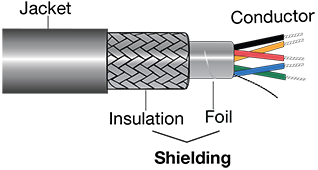

A shield is typically constructed of layered aluminum and polyester. In addition, as illustrated in Figure 2, braided strands of copper (or other conducive metal) can function as an additional conductor when placed in electrical contact with the aluminum layer. Although the shield’s construction can be longitudinal or spiral-shaped, longitudinal shields are recommended because of their lower inductance.

Figure 2: Shielded cable

Cables are available with various degrees of shielding and shielding effectiveness. The amount of shielding needed depends on several factors, including the electrical environment in which the cable is used, cable diameter, weight, and flexibility, and overall cost.

Types of Cable Shielding

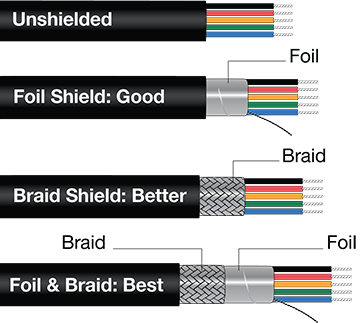

Figure 3: Types of Shielding (Foil, Braid, and Multishield)

- Foil Shield: A foil shield consists of a thin aluminum layer, which is attached to a polyester carrier to increase durability. Foil shields offer 100% cable coverage, which is required for electrostatic shield protection.

- Braid Shield: A braid is a woven mesh of bare or tinned copper wires. The braid offers a low-resistance path to the ground and can be terminated via soldering or crimping when a connector is attached. Copper has higher conductivity than aluminum, and the weave offers more mass for noise conduction. Braid shields minimize low-frequency interference and have lower DC resistance than foil; however, they do not provide 100% coverage. They typically offer between 70% and 95% coverage, depending on the tightness of the weave. A braid shield offers effective EMI/RFI resistance for power, control and data applications.

- MultiShield (Foil & Braid): For extremely noisy environments, a combination of foil and braided copper is recommended. Multishield cables are often also physically stronger. In many multiconductor cables, individual pairs are shielded with foil for crosstalk protection between the pairs, while the overall cable is shielded with foil, braid, or both.

Belden/Alpha Wire Cable

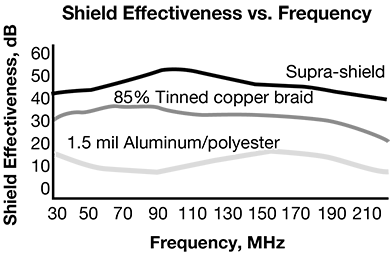

Belden/Alpha Wire have designed several shielding technologies in their cables, including Beldfoil® (Multiple Pair Individually Shielded Cables) and Duofoil® , a shield in which metallic foil is applied to both sides of a supporting polyester or polypropylene film. Belden/Alpha Wire’s Supra-Shield® uses a unique triple laminate aluminum/polyester/aluminum foil tape, which increases shielding effectiveness by reducing shield resistance (Figure 4).

Figure 4: Supra-Shield Foil-braid shielding vs. other types of shielding

Xtra-Guard® 2 Multicore Cable

Buy Now

DataBus® ISA/SP-50 PROFIBUS Cable

Buy Now

EIA Industrial RS-485 Multi-Conductor Cable Buy Now

Audio Control Multipair Cable

Buy Now

Practical Guidelines for Effective Shielding

The primary function of the shield is to restrict signals from radiating out of the wire or cable. A shield also prevents external signals or interference from getting into the wire or cable.

- A cable should have sufficient shielding to satisfy the application requirements. In moderately noisy environments, a foil can provide adequate protection; however in noisier environments, braids or foil-braid combinations would be more effective.

- The durability of the shield should match the application. Cables that will be flexed repeatedly should use a spirally-wrapped shield. Foil-only shielding should be avoided because flexing can damage the foil.

- Connectors must have the same shielding effectiveness as the cable.

- The cable should be grounded at one end in order to eliminate ground loops, which are a common source of noise.

Summing up: Effective Shielding in Cables

Proper shielding techniques in cables are required in modern systems where EMI and RF are potentially present. Proper shielding prevents EMI and RF from penetrating cables and causing noise and other anomalies. Belden/Alpha Wire cabling uses several advanced shielding techniques, which provide effective blocking of unwanted signals in a variety of applications, including data, video, and audio. Belden cable is used in a wide variety of industries, including broadcast, transportation, security, consumer electronics, and energy.

For more information on cables and shielding, check out our eBook: Wire & Cable for the Industrial Environment.

What kind of electrical noise or EMI problems have you had in the past that were solved with shielded cables?

Please tell us in the Comments section below.