An overview of potential problems in fiber optic communication and ways to reduce them.

Avoiding Signal Loss in Fiber Optics

Fiber optic communication uses pulses of light to transmit data along thin strands of glass or plastic. Because the technology is reliable and supports long distances with higher speeds than other connections, fiber optics have revolutionized the telecommunications industry. The advantage of high-speed, buffer-free, and high bandwidth Internet make fiber optic communications systems the preferred choice for telecommunications backbone infrastructure, Ethernet systems, broadband distribution, and other network applications. Compared to copper-based Internet, fiber optic communications can accommodate noticeably higher data rates with lower loss levels in the transmission medium. Fiber optic systems, however, can only be considered a panacea for some problems. Fiber optic loss is a concern during connector and cable selection and installation. This article discusses the common issues experienced in fiber optic performance.

Common Problems with Fiber

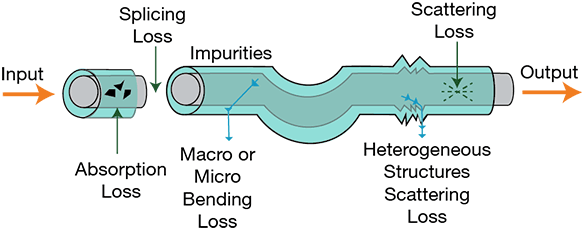

Attenuation is the loss of optical power due to absorption, bending, scattering, and other loss mechanisms that may occur when the light is transmitted through the fiber. Attenuation results in a weakened signal strength. Fiber optic losses can be categorized into two types: (i) intrinsic, which includes losses due to absorption, dispersion, and scattering, and (ii) extrinsic, which includes losses due to splicing, bending, and losses at the connector.

Extrinsic Fiber losses

Extrinsic losses in optical fiber occur due to reflections, roughness on end faces, angular errors, or radial misalignment. The following are the various types of extrinsic losses.

(i) Bending loss (radiative loss): Bending losses can occur whenever an optical fiber bends or flexes. Two types of bending loss exist:

- Macro-bending Loss: Macro-bending losses occur due to radii bends larger than the fiber diameter. With slight bends, losses are extremely small. As the radius of curvature decreases, losses increase exponentially.

- Micro bending Loss: Micro bending losses are associated with small perturbations of the fiber, induced by non-uniformities during manufacturing or stresses during the cabling of the fiber.

(ii) Splice Loss: Optical power loss at the splicing point is known as splice loss. Splice loss cannot be completely avoided, but proper methods can reduce it substantially.

(iii) Insertion Losses: Insertion or connector losses are potential losses in signal strength that can arise when a device or a connector is connected to an optical fiber transmission line. End-face defects such as cracks, contamination, pits in the fiber, misalignment between the cores, and poor contact between cores can cause insertion losses.

Figure 1: Insertion losses in optical fiber

Intrinsic Fiber Losses

Intrinsic fiber optic loss or attenuation occurs within the fiber optic core. There are several types of intrinsic losses.

- Scattering loss occurs when light interacts with density fluctuations in the fiber. The light is not absorbed, but sent into another direction. Scattering losses occur due to microscopic variations in the material density, compositional fluctuations, structural homogeneities, and manufacturing defects.

- Absorption loss describes losses caused by the presence of residual impurities in the fiber optic cable. This loss mechanism relates to the composition and fabrication of the fiber. Absorption causes dissipation of the transmitted optical power in the optical waveguide in the form of heat.

- Dispersion are distortions in the optical signals that can occur as they propagate through optical fibers. Dispersion can be intramodal and intermodal. With intermodal dispersion, the pulse broadens due to the difference in propagation delay between modes in multimode fiber. Intramodal or chromatic dispersion describes the way the pulse spreads in single-mode fiber due to a material’s dispersive properties, or the variation of refractive index as a function of wavelength.

Figure 2: Different types of losses in optical fiber

Fiber Optics

Shop our wide variety of fiber optics connectors, adapters, and cable assemblies by Molex.

Don't forget to join our discussion.

Dealing with the Challenges of Fiber

It is impossible to eliminate optical fiber loss; however, proper planning, careful installation, better quality materials and components, as well as regular testing of the fiber ensures the best results. Fiber loss in a network can be minimized by following these procedures:

(i) Polish and clean the ends

A rough cut can cause scattered signals and trap dirt particles around the edges. Because the fiber is hair-thin, airborne dust particles can scatter and absorb light signals. The ends should be cut with a cleaving tool, polished with a professional polishing kit, and then wiped with a lint-free isopropyl alcohol wipe.

(ii) Minimize end gaps

Signal losses occur if there is a gap between two fibers in an optical fiber connection. Such a gap allows the air to refract the emerging cone of light, which can cause signal loss. The fibers should not be cut at an angle and the connecting fibers should line up perfectly without any gaps.

(iii) Connect the same-size fibers

A network may require the connection of two different types of fiber. Losses will be minimal if the signal travels from a small fiber to a larger one. The signal should never travel from a large fiber to a smaller one, as this will result in substantial losses due to the difference in core size and the numerical aperture of most small core fibers.

(iv) Avoid unnecessary bending

The cable radius of the optical fiber cable should match the manufacturer's recommended installation bending radius. The installation route should be free of sharp bends. The use of suitable conduits during installation will minimize damage arising from bends.

(v) Protection of the connection

An optical fiber connection should be shielded from dirt, water, salt spray, high/low temperatures, and shock. Shielding takes the form of a purpose-built box or high-quality, rugged connector housing. Both must have a secure locking mechanism to protect the interface from ingress.

Molex Fiber Optic Cables and Connectors

Passive media components such as cables, cable splices, and connectors have the potential to cause attenuation in optical data links. Molex offers ruggedized fiber optic cables and connectors with low signal loss for a broad range of data transmission solutions.

Molex FlexiBend MPO/NTP cable assemblies

Molex FlexiBend MPO/MTP cable assemblies (Part No.1062250013) are outfitted with a flexible shape holding boot to ease cable routing, and accommodate low-profile installations where cabinet doors or front panels might interfere with conventional straight-style bend-limiting boots. FlexiBend optical cable assemblies allow cable exits in varying positions, from straight to a 90° angle. FlexiBend cable assemblies are used in a wide variety of applications, including communication and industrial equipment cabinets, medical, and aerospace/defense applications.

Molex 106397 Series LC2+ Fiber Optic Connector

Molex’s LC2+ connectors have greater durability and robustness than the industry standard plastic connectors. The LC2+ series are the industry’s only connectors that feature a metal housing, providing a high-performance discrete fiber solution for installations in harsh operating environments. Molex also offers LC2+ cable assemblies.

Summing up: Avoiding problems in fiber optic networks

in partnership with

The advantages of fiber optics, such as higher bandwidth and error free transmission distance , make it a compelling alternative to copper wires for data transmission. During the design and installation of a fiber optic network, factors that cause link loss and signal degradation must be considered. The implementation of fiber optic cabling best practices will ensure the proper environment for a fiber optic network. Molex offers a complete line of high-performance fiber adapters and connectors that are well-suited for implementing fiber optic connectivity in data centers and industrial environments.

For more information, check out our Essentials on Fiber Optics.

Have you tried fiber Internet yet and is it available in your area?

Please tell us in the Comments section below.

-

Fred27

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

Fred27

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children