A comparison of various methods of making cables for electronic systems. Take the Connectors Quiz

Making Connections in Electrical Systems

Cable connections play an important role in the operation of any electrical system. Choosing the right cable and connection ensures proper operation, durability, and usability. Some of the common tasks required when constructing cables include stripping the cable, cutting strands, and twisting wires. Methods of attaching the connector to the cable include soldering and crimping. Cables should also be built with proper strain relief, so that unnecessary stress on the connection joint can be avoided.

What is Cable Termination?

Cable termination is the process of attaching the cable to a connector, terminal, or another electrical device. There are several cable termination techniques, and the correct termination method should be used based on the application. The key factors to be considered when terminating cables include cable type, voltage and current, environmental conditions, ease of use, durability and compliance. We will take a look at the most common type of termination used along with its advantages and disadvantages.

What are the Strengths and Weaknesses of Soldering?

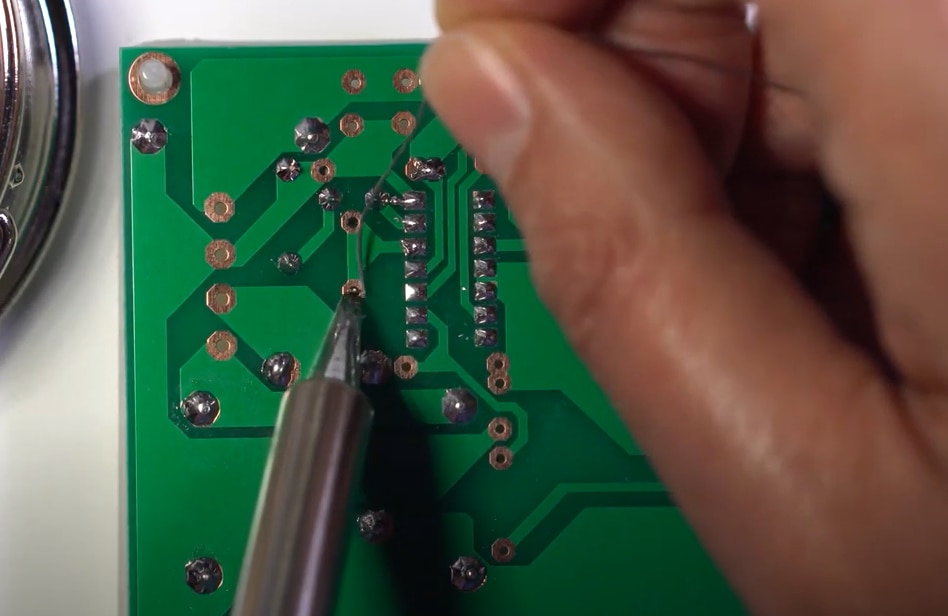

Figure 1: Soldering a PCB

Source: Shabaz/element14

Soldering is the process of joining two or more metal components, by melting solder (a metallic alloy with a low melting point). The melted solder flows into the gap between components, and once cooled, solidifies, forming a strong and permanent bond.

Advantages

- Reliability: Soldered joints are strong and durable, providing a reliable and permanent bond between metal components.

- Low Cost: Soldering is a low-cost method of joining metal components, making it an attractive option for many electronics applications.

- Versatility: Soldering can be used to join a wide range of metal components, including wire, circuit boards, and metal components of varying shapes and sizes.

- Electrical Conductivity: Soldered joints provide good electrical conductivity, which is important in many electronics applications.

- Repeatability: The process of soldering can be easily repeated, making it possible to make multiple joints quickly and efficiently.

- Flexibility: Soldering allows for easy modification and repair of electronics, as the joints can be easily melted and re-soldered.

Disadvantages

- Temperature sensitivity: Some electronic components may be damaged by the high temperatures used in soldering, which can limit the types of components that can be soldered.

- Limited Strength: Soldered joints may not be as strong as joints created using other techniques, such as crimping.

- Poor Performance at High Temperatures: Soldered joints may become weaker at high temperatures, making them less suitable for high-temperature applications.

- Unsuitable for field installation: Soldering is a complex process with power and environmental requirements. Some environments may not be suitable for soldering. Soldering is also more time consuming than other techniques.

- Limited Precision: The process of soldering can be imprecise, making it difficult to achieve tight tolerances or precise joint configurations.

- Environmental Considerations: Some solders contain toxic metals, such as lead, that can be harmful to the environment and to human health if not properly handled.

What is Crimping?

Figure 2: Crimping a contact for a circular connector

Source: Bulgin

Crimping is a method for joining metal components in cables and wiring systems. In crimping, a connector is attached to the end of a cable by compressing the metal with a crimping tool. The compression deforms the metal connector, creating a secure mechanical connection between the connector and the cable.

Figure 3: Bulgin 14025 Crimp Tool

Advantages

- Strong and Reliable: Crimped connections are strong and reliable, making them well-suited for applications where durability and reliability are important.

- Fast and Efficient: Crimping can be faster and more efficient than soldering, which is helpful when making multiple connections.

- Heat is not required: Crimping does not require heat, making it safer and more suitable for use with temperature-sensitive components and in applications where heat could damage other components.

- Easy to Use: Crimping can be performed using simple hand tools, making it a convenient method for field installations.

- Cost-Effective: Crimping can be a cost-effective method for joining metal components, as it does not require specialized equipment or materials.

Disadvantages

- Limited Reusability: Once a crimped connection is made, it is difficult to separate the components without damaging them. This limits the ability to reuse or reconfigure the components.

- Quality Control: Proper crimping technique and the use of the correct crimping tool are important to ensure a secure and reliable connection. Improper crimping can result in unreliable connections, or connections with a high resistance point.

- Limited Precision: Crimping can be less precise than other methods of joining metal components, such as soldering.

- Potential for Damage: Improper crimping technique can result in damage to the components being joined, which can impact their performance or cause problems in the electrical system.

Buccaneer Connectors

Shop our wide variety of Buccaneer Series connectors by Bulgin.

Don't forget to join our discussion.

Other Methods of Terminating Cables

Soldering and crimping are the most popular methods for connector installation; however, there are other methods of installing connectors. These include screw terminations, push-on, twist-on, and compression.

A screw termination is an easy-to-use method where the wire is inserted into the terminal, and held in place by a screw that is tightened onto the wire. The screw compresses the wire against the terminal, creating a secure and permanent connection.

Advantages

- Strong and Reliable: Screw terminations create strong and reliable connections that can withstand stress, vibration, and other conditions that could impact the connection.

- Easy to Use: Screw terminations are simple and straightforward to use, and can be performed using basic hand tools.

- Versatile: Screw terminations can be used with a wide range of wire sizes and types, making them a versatile option for many applications.

- Cost-Effective: Screw terminations are relatively inexpensive compared to other methods of joining wires to terminals or connectors.

- Reusable: Screw terminations can be separated and reused, making them a good option for applications where the components may need frequent maintenance or reconfiguration.

Disadvantages

- Time-Consuming: Screw terminations can be time-consuming to install, especially when making multiple connections. This can be a drawback in applications where fast and efficient installation is required.

- Limited Precision: Screw terminations may not be as precise as other methods, such as soldering, and may not be suitable for applications where tight tolerances are required.

- Quality Control: The quality of the connection is dependent on the accuracy and consistency of the screw tightening process. Under-tightening can result in weak or unreliable connections, while over-tightening can break the wire.

- Compatibility: Screw terminations may not be compatible with certain types of components or in certain applications, such as high-frequency or high-temperature applications, where the screw tightening process could damage the components or affect their performance.

- Reliability: Screws can become loose over time, leading to weak or unreliable connections.

Push-on and twist-on are two additional termination methods. Both provide a reliable connection between the cable and connector.

- Push-on: A wire is inserted into a connector and held in place securely by a spring-loaded mechanism. This method is typically used for small-gauge wires and is often used in low-voltage applications, such as audio and video equipment.

- Twist-on: The wires are twisted together and then inserted into the connector. The connector locks the twisted wires in order to make a secure connection. This method is typically used for larger-gauge wires and is often used in high-voltage applications, such as power distribution systems.

Buccaneer Series Connectors from Bulgin

Bulgin’s range of Buccaneer Circular Connectors offers reliable and robust connections for power, signal and data. For use in challenging environments, the Buccaneer range includes IP66, IP67, IP68-rated connectors, as well as waterproof connectors that are IP69K-rated.

Circular Data Connectors

The dustproof and waterproof Data Buccaneer range includes a wide variety of sealed circular connectors explicitly designed for Ethernet, USB, and SMB applications. Ethernet Buccaneer connectors satisfy Cat 5e requirements for data rates up to 100Mbps. USB Buccaneer connectors are designed to fulfill USB version 2.0 specifications for data rates up to 480Mbps, while SMB Buccaneer connectors have a frequency response of up to 4GHz. The Buccaneer series are well suited to a variety of industrial and harsh environment applications, both internal and external, where protection against the ingress of dust and moisture is a system requirement.

Circular Power Connectors

The Power Buccaneer range comprises the miniature 400, Mini, Standard, 900, 7000, and 6000 Series. Included in each range are a flex cable connector, Inline cable connector, and panel mounting connector options. Over-molded versions of the 400 series and Standard Buccaneer provide safe, secure, and tamperproof cable termination. The Buccaneer power connector range offers a wide choice of ruggedized plugs and receptacles providing 2 to 32 poles, and power ratings up to 600V and 32A. Buccaneer connectors are available with crimp, screw, or solder terminations.

Buccaneer EXPlora Series Circular Power Connector EXP-0921/05/S

Buccaneer 9000 Series Circular Power Connector PXP9011/04/S/1

Buccaneer USB Sealed Connector PX0842/A

Buccaneer Ethernet Modular Connector PX0834/B

Summing up: What are the Best Ways to make a Cable?

in partnership with

There are a variety of ways to attach cables to connectors, each with its own strengths and weaknesses. The proper termination method should be chosen based on the requirements of the application. Applications with volume connections might need a fast termination method, while equipment that is frequently upgraded would require reusability. The Buccaneer range of power and signal connectors from Bulgin offers the option of solder, screw, and crimping contact terminations. When properly terminated, cables with Buccaneer connectors are reliable and secure, and have the durability to withstand installation in harsh environments.

What kinds of cables do you typically make and what's your preferred method for making them?

Please tell us in the Comments section below.