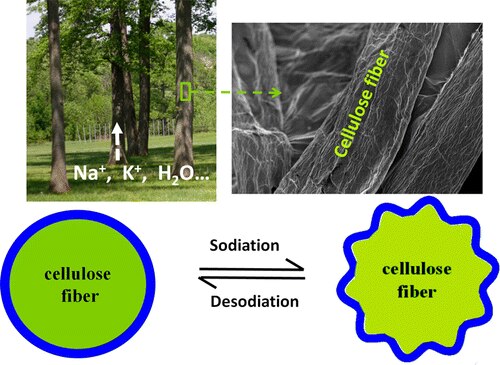

Wood based battery concept (via Hongli Zhu & NANO Letter)

Lithium-ion batteries can be found in almost anything from mobile devices to electric vehicles. While they have a lengthy recharge cycle and a reduced loss of charge when not in use, they are not cost effective to produce and are hazardous to the environment as well as humans if damaged. Lithium-ion batteries are designed using an anode typically made of graphite or carbon, a cathode made from lithium-cobalt oxide and an electrolyte usually made with a lithium salt in an organic solvent (depending on the battery type). Engineers from the University of Maryland have designed a new type of rechargeable battery that replaces the lithium with sodium, which is not only cheaper to use but also quite a bit safer for the environment. Sure, there are already batteries that use sodium as its charge medium; however, they make use of a tin anode that eventually turns into a sodium-tin alloy after a series of charges (around 20 charge cycles). This process often makes the battery shrink and swell in size thereby making the anode extremely brittle and prone to damage but the engineers have found a way around this problem by incorporating wood into their design.

The engineering team, led by Hongli Zhu, looked to nature for help in solving the problem of the tin anode becoming brittle after so few charges and found that trees could hold the answer. They noted that wood fibers in a trees make-up often hold mineral-rich water taken from the ground they are planted in and therefore excellent at storing liquid electrolytes. The engineers then designed their sodium-ion battery using tin-coated wood fibers (2500 nanometer thick wood fibers encased by a 50 nanometer thick tin layer) as the battery’s anode, which can handle the stresses of expansion and contraction during the charging/discharging cycles. They tested their new battery design and found that after hundreds of charging cycles the wood would become wrinkled but was still structurally sound. Computer models showed that those wrinkled wood fibers would actually dispel that stress of charging/discharging cycles which allows the battery to be charged many times over than conventional tin-only sodium-ion batteries. The batteries anode still goes through a chemical change resulting in the brittle sodium-tin alloy but the wood fibers act as a mechanical buffer (or a shock absorber of sorts) and effectively offloads the stress when the tin changes. Using the wood fibers along with sodium greatly reduces the cost of manufacturing over lithium, which is a rare-earth metal and a dwindling resource. Do not expect to see sodium-ion batteries in mobile devices anytime soon however, as it still is not as efficient as lithium-batteries at storing a powerful charge. Instead, the engineering team is looking to make large battery energy storage systems ideally suited for renewable energy plants (solar, hydro and wind).

C

See more news at:

Top Comments

-

DAB

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

DAB

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children