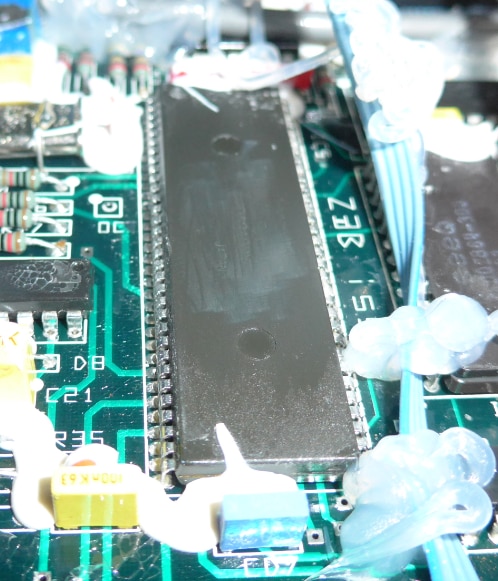

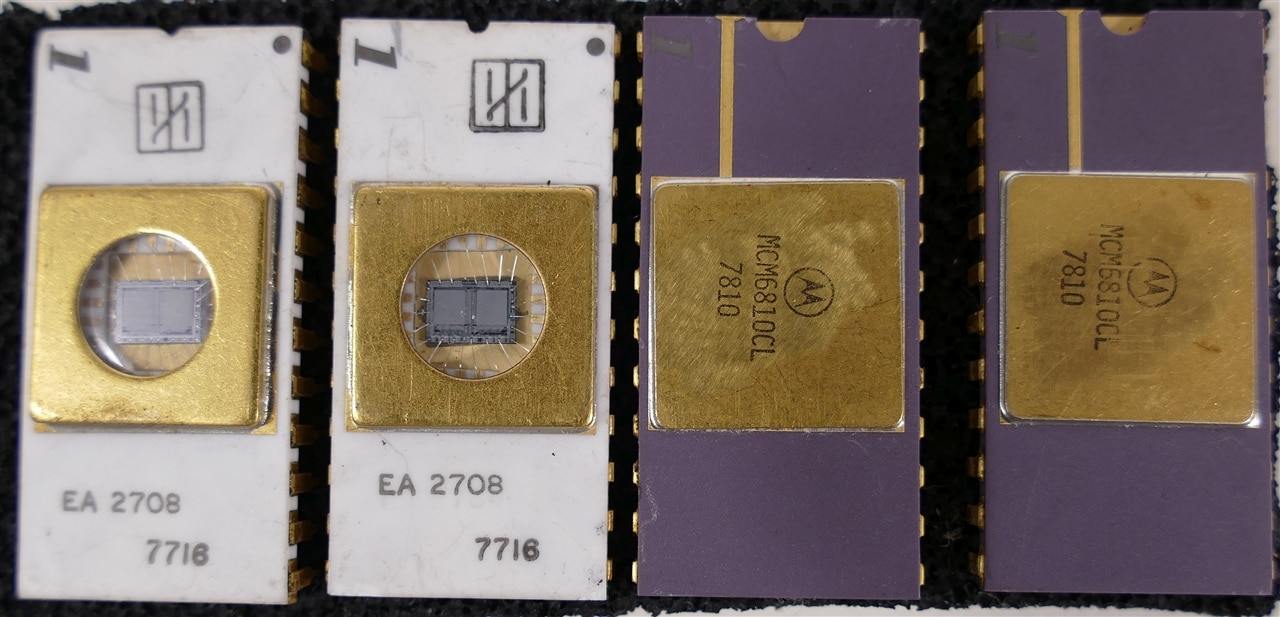

I came across some old and famous chips in one of my parts cabinets. Does anybody else keep old chips? and why?

Note that these were pretty expensive when they were purchased, especially the gold plated ceramic chips.

I expect most of these are part numbers that everyone has heard of.

Have you designed with any of these famous chips?

Brownie points if you can figure out the date codes.

What chips are buried in your archives?