You're working on a project, maybe at work? Maybe at home. You have your workbench and that might be tidy (we asked about that before... and I'm sure we will again).

But I have all of these resistors! What do I do..

You're working on a project, maybe at work? Maybe at home. You have your workbench and that might be tidy (we asked about that before... and I'm sure we will again).

But I have all of these resistors! What do I do..

I have a parts storage drawer, they're labelled!

Nowadays I work mainly in software, so I don’t deal with hardware components on a daily basis—just a few evaluation boards and some Dupont cables. Still, everything has its own place in the office and, of course, it all has to be properly noted in the inventory Excel worksheet.

At home, I do keep a small collection of components. Some of them remain in their original packaging thanks to a surprisingly decent presentation, while others are grouped into small boxes with dividers.

One of my proudest achievements was standardising, organising and labelling SMD PCB components for a medium-sized electronics manufacturer during my first job as an engineer. Seeing the before and after of that place was properly brilliant, and watching everything run more efficiently afterwards made the whole effort absolutely worth it.

I keep all of my components in the original bags. The components are almost exclusively SMD, so they don't take up too much space. The bags are held inside of six 15 Quart storage boxes that are grouped as follows:

Based on projects, I have several smaller storage units that I used for assembly. I remove components from tapes and tubes into the storage boxes at the beginning of builds (usually 10 - 20 board). Upon getting and order, I do a quick inventory and order any shortages. Then I kit up according to the BOM.

So far, this has been working well.

It's very simple.....

The parts that I feel closest to and derive the most satisfaction from are located within arms reach of the desk. The parts that have behaved badly are banished to the far ends of the lab where I may visit them once or twice as I see fit. Most of the rest of the parts are grouped in piles next to the project they will eventually belong to, waiting patiently for a true connection and purpose in life. There are some older parts that have become boxed and may never see light again, unless they become repurposed with a greater mission or to be displayed prominently in a window or on a shelf.

Components for a specific project that I have had to purchase stay in the packaging they arrived in - sometimes even including the shipping box. The general components that I have on hand live in parts drawers (mostly). Every once in a while, I rediscover a Newark box or bag. Sometimes I'm even able to remember why I bought those components. If not... they get filed in the parts drawers.

I take a hybrid approach to storage. Which means it's organized chaos.

For projects I'm currently working on, the workbench is the best place to store the bits and bobs. Usually, in their original bags until the first item gets built, then it can be "piled" up in loose groups.

But for surplus components, it's a literal junk box (one of those plastic tubs without a divider) where the remainder of the components inside labelled bags (sometimes not) are just carelessly tossed in. Inventory management? Never heard of it. I just go "uh, I thought I had one" and will rifle through the box in its entirety to see if I can find it. This definitely goes for my SMD components ...

But for through-hole components, organisation is the norm. I 3D printed some interlocking drawers to sort my E24 resistors. I use stackable divided plastic trays to store larger components like electrolytic capacitors, connectors or bulk items (thousands of a given value). I don't know why, but my through-hole life is very much more organised and labelled.

Despite the mixed mess ... I'm still doing okay - I still know that I have just one BSS138 transistor in my junk box and I should probably order some more ...

As for reels ... thankfully, I don't order that many components for hand-soldering ...

- Gough

I use many storage and organizing methods, everything from "disposable" food packaging to plastic shoe boxes, to proper component cases, to custom dispensing organizers, but always just enough to allow parts to be found fairly efficiently. The more a type of part is used, the better it gets organized. I do not have a list or database of parts.

Another thing that's really useful and it (occassionally) allows me to let my workbench become my storage area is distributor labelling on the bag. My personal preference is Mouser labels. Part no is clearly displayed (and doesn't fade, like Farnell labelling does) and the part description is good enough to give you most of the key specs. Digikey also pretty good and it also has a customer reference field, which is really helpful when ordering components for a large prototype board. Here I tend to put the PCB identifier in this field. Then it's easier to identify where that components goes on the PCB if when you're hand placing components onto the board for reflow.

I usually keep the development kits in the boxes it comes in along with the ESD cover.

If I feel like I have abused the box long enough, I upgrade the development kits by placing them in a cheap plastic box.

I miss option named "All of the above". Most parts I store in boxes like these:

But some parts I remain in MSL rated packages which they come in.

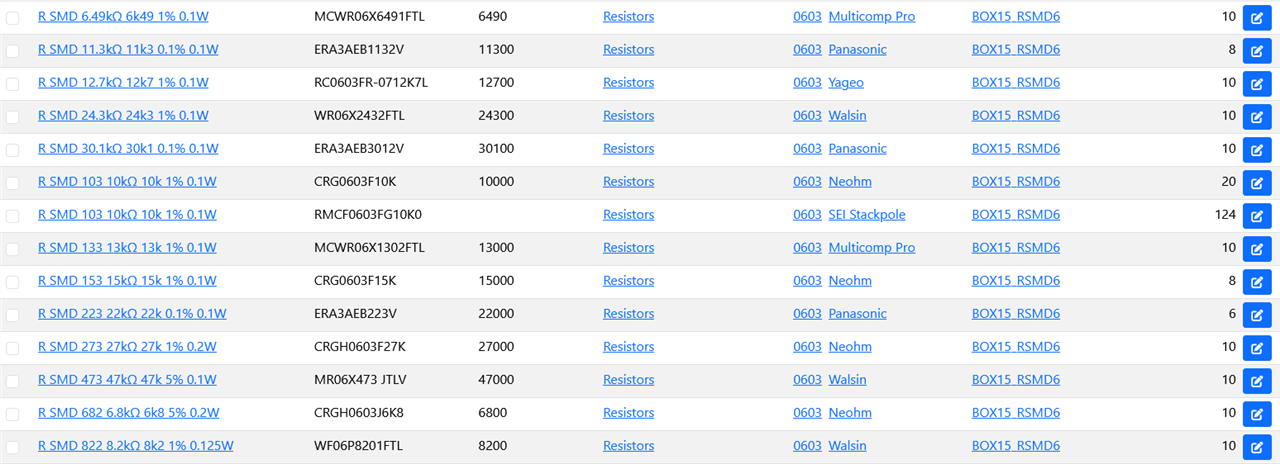

But I consider more important some system to effectively and quickly search for parts. I use PartDb for several years for this purpose. For example, in case of RSMD6 box shown above: