Alps Alpine’s force sensor employs a piezoresistive method using Si semiconductor elements. They detect loads with a piezoresistive element manufactured using MEMS processes. The new HSFPAR007A is the smallest in the industry (according to Alps Alpine research as of June 2020) and can be used for a wide range of applications such as stylus pens, other input devices, and pressure application adjustment for gripping by robot arms.

Force sensor detection principle

The piezoresistive method is a detection method that uses the piezoresistive effect. When mechanical strain is applied to a semiconductor crystal (Si), the amount of electron movement changes due to a change in the internal energy structure, and the electrical resistance is reduced. It is a changing phenomenon.

As shown in the figure on the below, the electrical resistance changes depending on the direction of the strain applied to the piezoresistive element.

As shown below, when a load is applied causing the diaphragm to bend, the change in structure of the piezoresistive element alters the resistance.

>In order to keep the size at a minimum, an analog output is used without the use of an integrated circuit.

Features of the force sensor

Industry's smallest size

Alps Alpine’s force sensor is the smallest in the industry to fit into the diameter of a small stylus pen.

(According to Alps Alpine research as of June 2020)

High linearty

Piezoresistive force sensors achieve higher linearity than other force sensors, but the Alps Alpine force sensors enjoy even higher linearity than piezoresistive products of other companies.

Alps Alpine's HSFPAR004A / HSFPAR007A achieving less than 2% FS*.

FS = Full span (output variation between 0 and 8N)

High Sensitivity

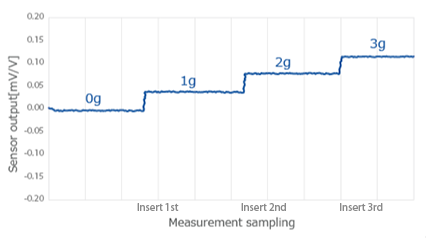

Alps Alpine's force sensor can detect minute stress of 1g (≒ 0.01N) level.

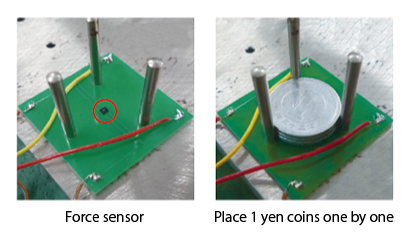

Experimental example

In an experiment in which a 1-yen coin (1 g) is superimposed on a force sensor, it can be reliably detected as shown in the graph. As mentioned above, the Alps Alpine force sensor has a high degree of linearity, so this can be achieved over the entire load range.

Signal amplification processing such as operational amplifiers and signal stabilization processing such as averaging is required to detect minute stress.

These characteristics make it possible to detect the pressure applied to a stylus pen tip, enabling very pleasant writing expression, for example in terms of fluency of pen use and repeatability.

High Reliability

Alps Alpine's force sensors have a guaranteed operating life of one million cycles when used with loads within the operating range (up to 8N). HSFPAR004A / HSFPAR007A withstands loads up to 55N, a 30-40% higher maximum load rating than earlier models.

Alps Alpine also supplies the HSFPAR303A, a module (for installation by FPC) that withstands up to 200N.