Im currently studying my third year Electrical and Electronics Engineering at Heriot Watt University. This semester we have a Project to complete as part of a team of fellow EEE students and Computing Students, and i though i would let the community know about it.

The majority of the project is technical, but we also have to look at it from a project management aspect, i will leave out the project management side to be nice. I will mostly be doing the digital design aspect of the project, but will most likely be helping out with the other aspects of the project, i will try and upload as frequently as i can. I will welcome any comments, or suggestions which you have.

Here is the specification that we were given

Project Background

Sensing is key to many autonomous systems and this project will be making extensive use of a variety of sensors to develop a system that can operate with a level of autonomy

Design ability is one of the key objectives of the engineering process. A successful design requires the application of a combination of creativity, skill, and the ability to analyse and synthesise.

The purpose of this design project is to provide an opportunity for these abilities, which you have begun to acquire in the first, second and third years of the course, to be exercised in conditions similar to those under which engineers work in industry.

Many industrial products and processes use a combination of computing, and embedded software and digital technologies applied to some physical system, the design project contains elements of each. This project is structured to give you experience of designing across artificial disciplinary boundaries, its successful completion requires you to exercise system integration skills.

Background

Snack-O-Mat is a newly formed company to produce intelligent solutions for sensor based snack systems. Their business model is to manage the design, delivery and maintenance of the automated equipment for a robotic supply system. However, they outsource the technical development of the equipment to 3rd party electro-mechanical design companies.

Their first project is with a company that runs a snack supply system that reads a card to indicate known allergies and automatically dispenses the required number of snacks to a user. They have specified the need for an automated analysis system to sort out the snacks which contain particular allergens.The analysis will be done (in a similar what to spectroscopy) by looking and the different colours present in the presented sample.

The company has contracted Snack-O-mat to design and deliver an automated system that will work in conjunction with the user to supply the required snacks.

A set of companies have been asked to bid for the contract by building and demonstrating a proof-of-concept unit. The final decision on which company gets the contract will be based on a public competition to be run in December 2017. At this event, each machine will be demonstrated and supported by the submission of a suitable technical document.

Specification

- 1. Design and build a small system that reads a user's card indicating what allergies the user has and gets an input from the user indicating how many snacks they require. The system reads the colours on the snacks to defines which allergens they contain. Then the allergen free snacks are to be dispensed. The system must ensure that the user is present whilst using the analysis system, but they must be at least 10cm from the machine. Upon analysis the required set of snacks should be dispensed automatically to the user.

- 2. The system should indicate if it was unable to fulfill the required action, i.e. if it does not have an adequate supply of snacks or there is some other issue

- 3. Once started, the machine is to run without operator intervention. It should however, interact with the user through the PC interface and any appropriate LED indicators to show the user what is happening, whilst ensuring the user remains present, but is not too close.

- 4. A connected PC will allow initial setup of working parameters and show progress of the machine

- 5. The system should have TWO distinct MODES.

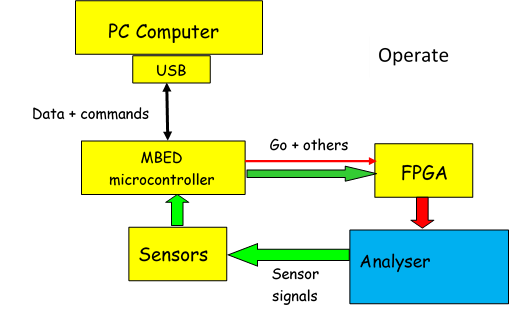

- • Operate mode

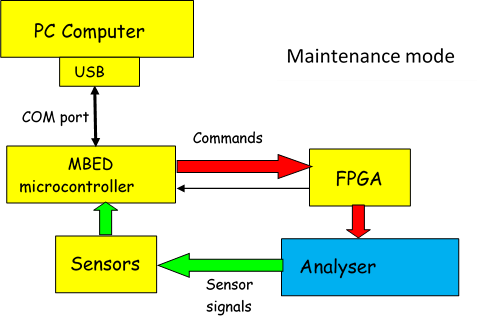

- • Maintenance mode

- 6. Operate mode is the normal mode with the machine selecting blocks of a specific size and checking the colour of the selected snacks.

- 7. The maintenance mode allows an engineer to test and diagnose any machine problems.

- 8. A PC computer will provide the following

- • Operate mode

- • Monitor progress and display appropriate data on screen

- • Maintain simple database of snacks that have been analyzed and those needing reprocessed.

- • Tell the operator, through a speech facility, what the machine is doing. This facility to be switchable between English and another language (e.g. French, Chinese, etc.)

- • Show result of the snacks that have been analyzed for allergens and the appropriate snacks dispensed.

- • Maintenance mode

- • Provide a facility to test the different aspects of the machine for maintenance purposes.

- • Move servo motors

- • Read sensors

- • Provide suitable GUI interface to run the maintenance commands

- • Operate mode

- 8. The Altera Cyclone FPGA system

- • Operate mode

- • Once a GO signal has been received, the FPGA unit will control all aspects of the actual snack sorting process

- • Show some simple information on the FPGA board displays

- • Maintenance mode

- • Receive commands from the MBED unit

- • Send command to FPGA

- • Move servos and motors

- • Operate mode

- 9. MBED unit

- • Operate mode

- • Communicate with the PC

- • Generate “go” command to FPGA

- • Read monitoring sensors and send to PC

- • Communicate with the PC

- • Maintenance

- • Communicate with the PC

- • Read commands from the PC

- • Execute these commands and return data to the PC

- • Read sensors and return data to the PC

- • Communicate with the PC

- • Operate mode

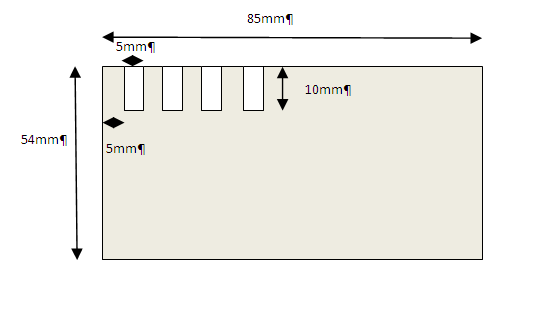

- 10. A card will identify the users' allergies. The user will then enter into the system the number of snacks required. The snacks will not be loaded into the system already sorted for allergens, but they will be stored together. The system will test each snack for allergens. The dispenser will indicate if it is unable to fulfill the required action, i.e. there when it runs out of suitable snacks in the machine. The user card will be the size of a credit card with FOUR notch areas, which can be filled, or cut-out. This would give 16 possible combinations.

Code number Allergy (colour) 0000 No allergy 0001 Red 0010 Green 0100 Blue 1000 Yellow 0011 Orange 0101 White 1001 Black

- 8. A PC computer will provide the following

- Insertion of the card will prompt a set of activities

- • Read card code

- • Check code against central data file and indicate any allergy issues.

- • Request entry of the number of snacks required

- • Check that machine can satisfy order

- • Indicate problem if machine has insufficient snacks

- • Dispense snacks if all is OK.

- • Prompt for user to collect snacks and card

- Insertion of the card will prompt a set of activities

- 11. Sorter to fit onto a 300mm by 300 mm baseboard. Height to be less that 500mm.

- 12. Teams may add additional features after agreement with the project manager.

Top Comments