What happened before:

For almost a year I have a vintage turntable from Perpetuum Ebner at home. It's not mine. It belongs to someone that asked me to fix it. And it turned out that fixing the motor would cost too much. I asked the owner to collect the tt. That hasn't happened yet and the machine is collecting dust at my home.

So I'll take the freedom to attempt a non-intrusive repair with modern components. I'm also thinking about making it an Enchanted Objects Design Challenge. |

In post 1 I present the turntable, talk about my previous repair attempts and brainstorm on some modding ideas.

In post 2 I'm measuring up the different gears, pulleys and wheels, and I calculate the speed of the original motor.

Post 3 is the first post on motor control. I'm reviewing the operation of the Infineon DC Motor Control Shield.

In post number 4 I'm using the enhanced PWM module of my The specified item was not found. Hercules LaunchPad to test drive the motor.

The table is spinning for the first time in post 5.

In post 6, I put it all together. I now have a turntable that works, with PWM speed regulation.

In this article I'm creating a sensor to measure the motor speed. That's the first step to get constant speed control.

Where can I measure speed?

There are many ways to measure the speed of this turntable. There's at least 5 parts that I can use: the motor, the belt, the tapped pully, the idler wheel or the platter.

I try to keep things simple for myself. Three of the options should always move at a constant speed, regardless of the platter speed: the motor, the belt and the tapped pulley.

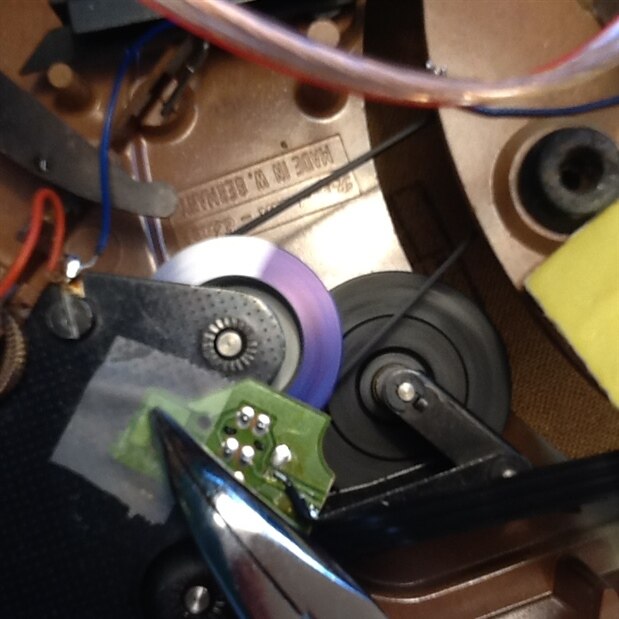

And that tapped pulley is the easiest of those three. It's got a flat surface at the back, there's room there to place a sensor, and there are good sensor mounting options at the right place.

Sensors

My sensor bin is empty at the moment. I used the last one in the coin detector of a drink dispenser.

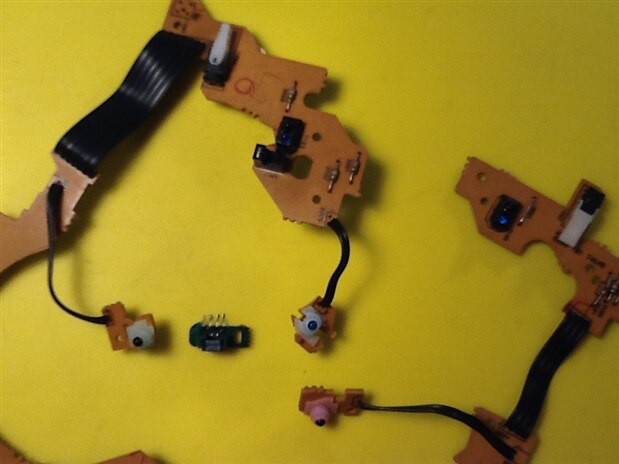

I checked my pile of discarded gear, and picked up a defect video player. These have a significant amount of mechanics in them. They're good for sensor harvesting.

And I wasn't disappointed: IR transmitters and receivers (some mounted in a plastic holder), an opto-coupler with gap (could be handy if I decide to measure the belt speed), and a device I haven't found any info on.

So that means that I can once again choose the simplest option. And that's one of those IR LED pairs mounted in plasic.

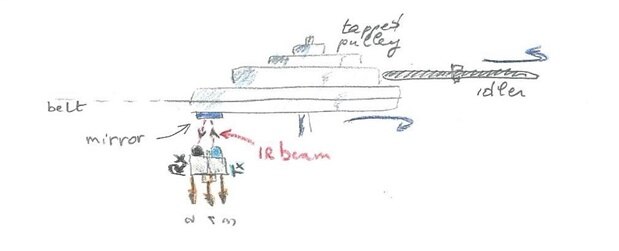

The combination of these two simplest options gives this possible solution:

make a small part of the backside of the pulley reflective with a tiny mirror, and mount the sensor pair close to it.

If I reuse the original PCB, I can use that as mounting point.

I tested this, and it works really well in practice.

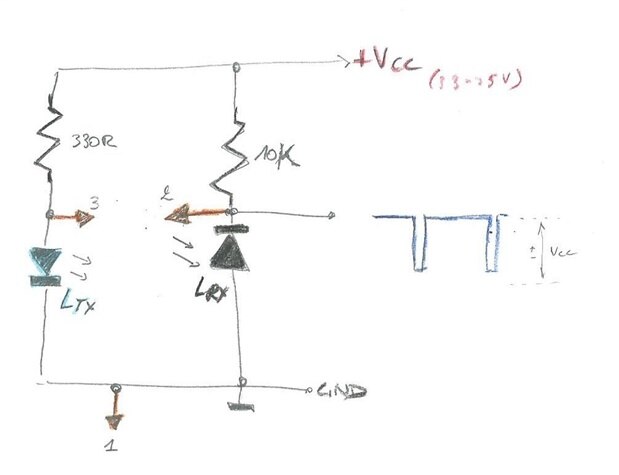

I get a nice pulse without bounce using this simple schematic:

The resistors have rough values here. They are the 330 Ohm and 10K ones that come with the typical Arduino kits.

I tested with 5V. I'll recalculate them when I adapt the circuit to 3.3V.

Here's what the output looks like on an oscilloscope. The measurement was done with the circuit taped in place and the motor spinning:

This signal is clean enough. I am going to use the eCAP (enhanced capture) module of the Hercules Launchpad to measure the speed and use it as the feedback data.

The firmware has to complete the controlled loop: a continuous check of measuring the speed and adjusting the motor driver signal.

Top Comments