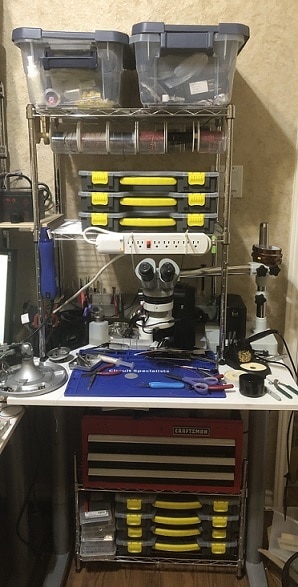

As I am waiting for my revised PCBs to arrive for my Road Test project, I have been doing some cleanup and organization projects in my office. This time I am working on my soldering station. I have rearranged my Worksurface and shelving system to increase storage space and improve the ergonomics (my Wife keeps telling me that when I work at the microscope I am so hunching over). I have raised the work surface by 3", improving the ergonomics, while at the same time lowering my modified toolbox (and removed a lower shelf), providing access to the upper tray (above the drawers).

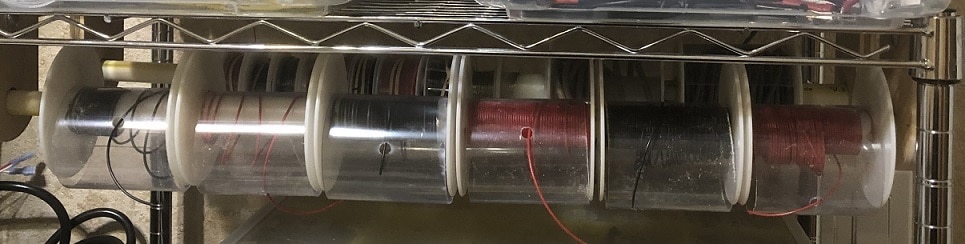

Above the work surface, I added more storage boxes (boxes and multiple compartment trays) and built some new racks for my wire spools storage.

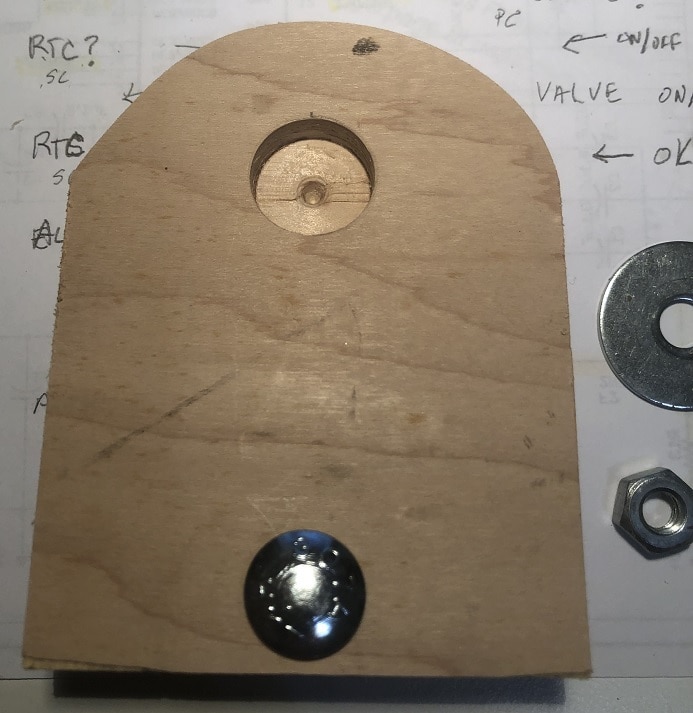

For the wire racks, I built up some custom rod holders that I can bolt to the bottom of one of the wire shelves. These rod holder mounts were cut out of 3/8" plywood and shaped on the bandsaw. A 11/16" hole, 3/16" deep were drilled into each piece to hold the 1/2" CPVC pipe.

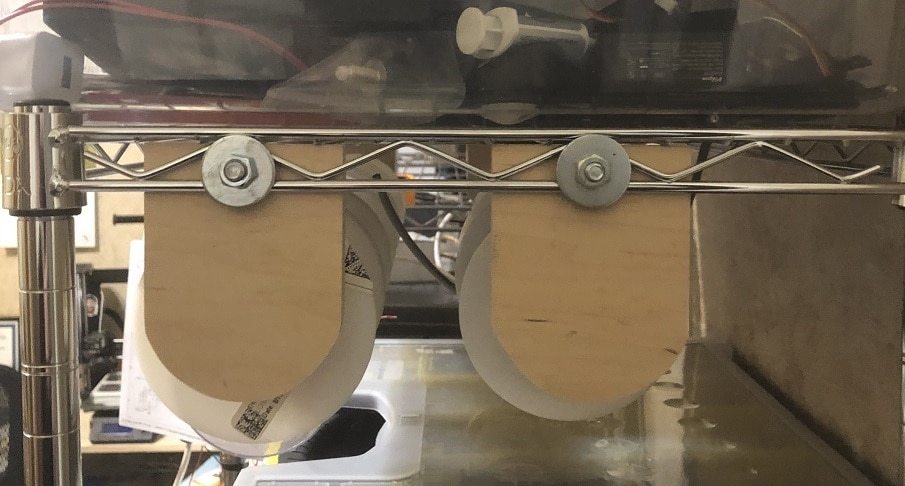

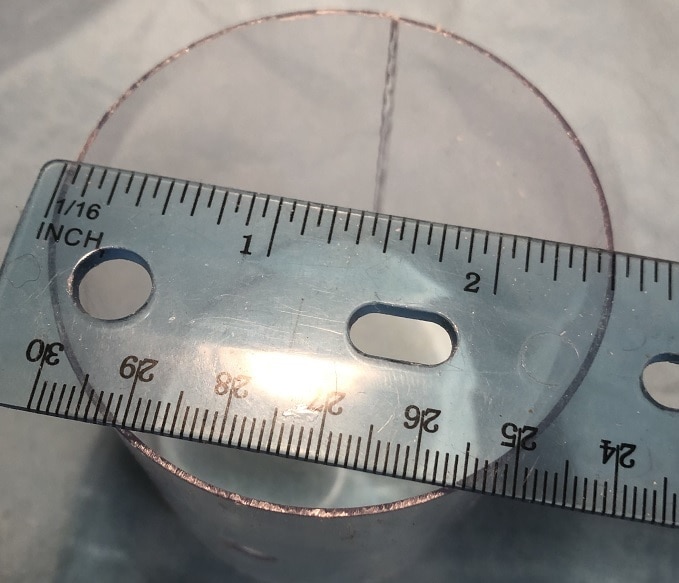

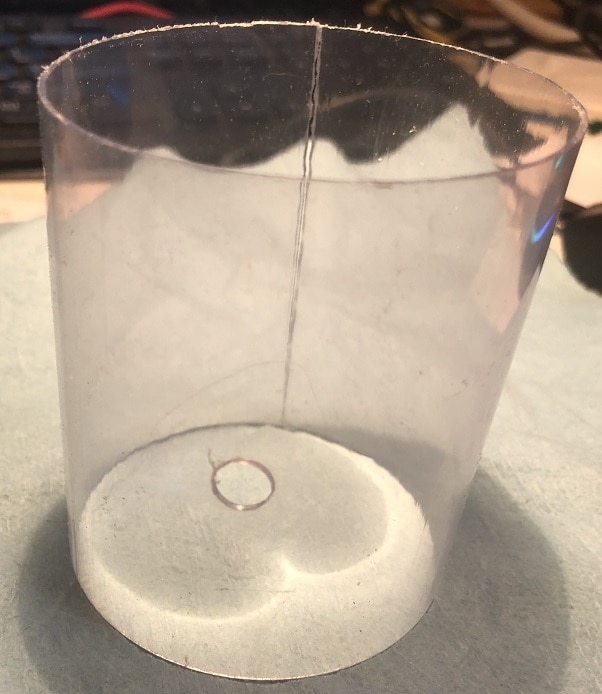

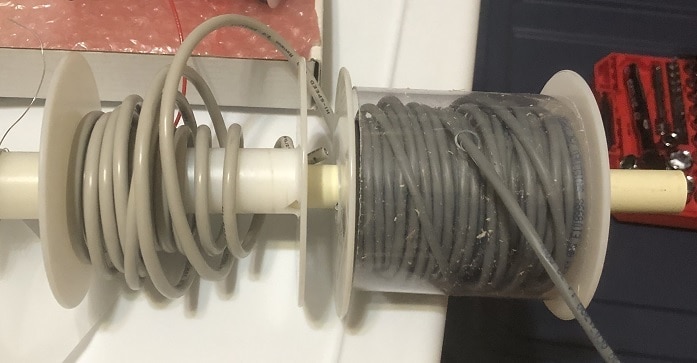

The Spool holders were attached beneath a shelf using a 1/4" carriage bolt, fender washer and a nut. A pair of holders and rods hold the 20 reels of wire. The wires looked pretty messy at first, so I decided to build sleeves to help contain the wire. I dug up some clear plastic 2 1/2" thin wall tubing that was a shipping container for some t-slot rails. I cut sections of the tubing to match the inside width of the wire spools (3", 1" and 3/4" wide), split one end and drilled a 1/4" hole in the sleeves.

Here is a side-by-side picture of a sleeved and unsleeved wire spool.

And here is a zoomed in picture of the newly mounted wire spool holders with sleeves in place. For the smaller diameter wire rolls, I used the same diameter tubing, but rolled in up a bit and used rubber bands to hold them tight. (visible in the back row in the following image).

I was very happy with the results, but also noticed that is time to go shopping for some wire as some of the rolls are almost empty.

Thanks for reading along.

Gene