In my prior blogs ( Post Christmas shopping find - TC2-DSO review.and TC2-DSO review - Continued ) I tested several leaded component with the TC2-DSO meter. This is all well and good, but I do not use many (if any) leaded components in my products/projects, so I really wanted to come up with a way to test components that I might actually use. Here is a design for testing 0603 and SOT-23 analog components.

I thought that a great starting point for a 0603 and SOT-23 device adapter would be some SOIC adapters that I have used in the past. With a single 4-pin header attached on one side I would have more than enough contact points for the TC2 meter. The adapter has two usable sides, one with 0.05" spaced pads, the other with 0.025" spaced pads. The 0.05" pad spacing is almost ideal for the 0603 and SOT-23 footprints.

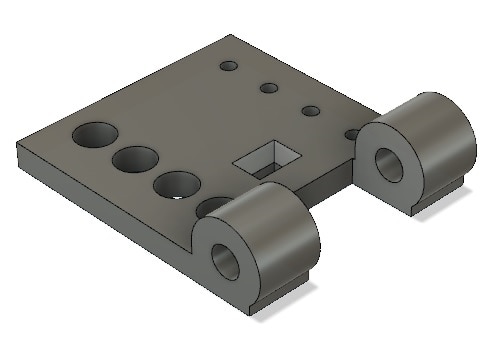

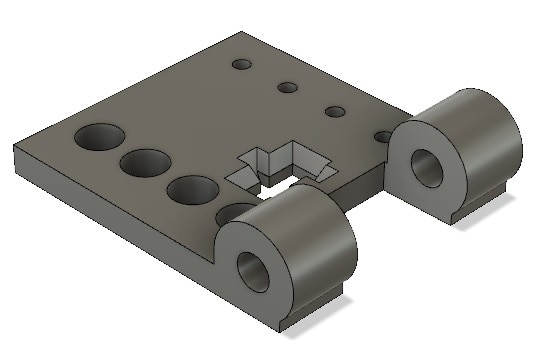

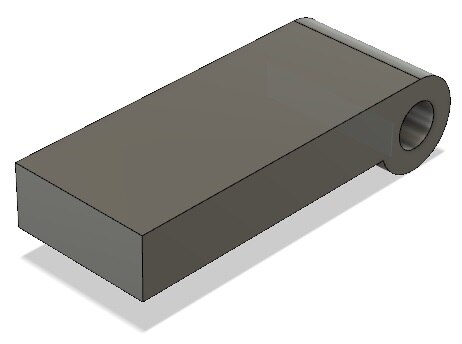

Next I designed some SMT chip holders in Fusion360 to hold and align the devices to the SOIC adapter board. Here is what I came up with:

The parts are designed with four clearance holes on one side (to align with the header solder to the SIOC adapter board, a four alignment holes that will provide a tight fit with another header the will pass through the SIOC adapter board and into the component holders. The two designs have different component outlines, with chamfers added to guide the components into the part outlines. A flip lid can be attached to either/both bases, with a 1/2" long 0/80 screw (thread tight on the base and oversized on the lid. Using a small rubber pad on top of the device should allow sufficient pressure to achieve good lead contact to the SIOC adapter board pads.

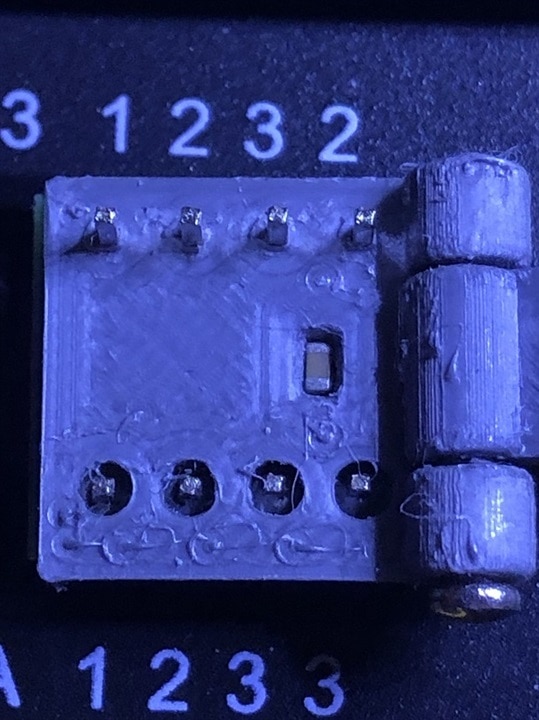

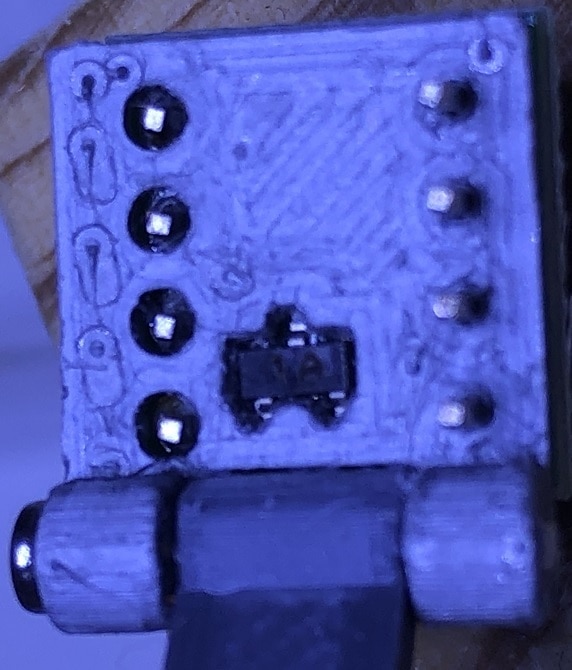

Next I printed the component holder parts and tried everything out. Now here is were I admit that it took three design iterations to get the fit and function that I was hoping for. Even with the multiple passes, I feel that the component holder parts were requiring a higher accuracy that my printer could provide, so the parts required quite a bit of cleanup to work. Maybe in the future I might need to get extruder tips with much finer holes for my printer. Here are the printed (and cleaned up) parts mounted on the SOIC adapter boards.

Next to test the component holders I inserted some SMT components into the holder openings, starting with the 0603 adapter (the rubber pad here was a small piece of a rubber band).

Flipping the lid and pressing it closed with my finger, the component made good contact and the TC2 was able to properly read the component value

Next I tested the SOT-23 component holder.

Flipping the lid and pressing it closed with my finger, the component made good contact and the TC2 was able to properly read the component value

There still a lot of room for improvement, but for the moment I think that I have achieved my goal.

Thanks for reading along

Thanks for reading along!