This blog will focus on performance tests run using other pieces of test equipment. It is rather challenging to test a soldering iron in a meaningful way, as thermal measurements are difficult to accurately achieve but I will still attempt it. In addition, I will use the WCU to test the supplied tips for offset and make some electrical measurements.

Table of Contents

Quiescent Power Consumption

A Tektronix PA1000 Power Analyser was used with a pure sine-wave inverter power source trimmed by a Variac to 230V (± 1%) for power consumption tests using PWRVIEW. As it turns out, there is zero standby power on the WXsmart and WXair units because they employ a physical power switch.

Quiescent power consumption with the WXsmart unit booted up, connected to Wi-Fi with no tools attached measured 5.895W which is reasonable.

The WXair adds another 2.434W which is also reasonable. Thus, the total stack while idling will consume around 8.329W.

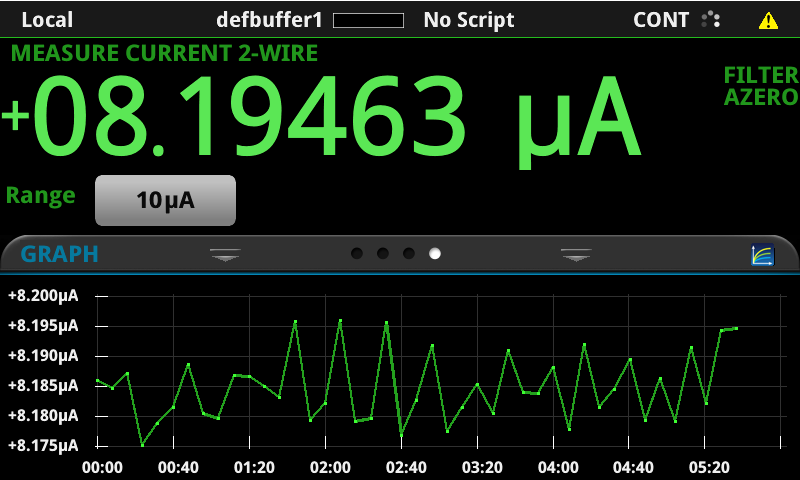

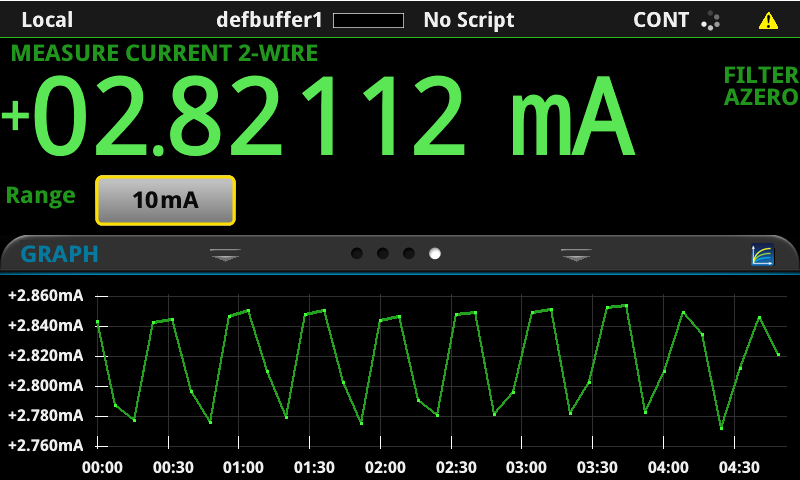

I also decided to test the WCU’s standby and measurement current using a Keithley 2450 SourceMeter.

When shut off, the unit sips a tiny 8.2µA from the battery.

While operating, it appears to consume about 2.8mA which means that a 9V battery should last around 196 hours of operational time.

Tip Temperature Offsets

In order to easily test the temperature regulation of the tips, I decided to calibrate each of them using the Weller WCU. In some cases, the calibration was repeated several times to ensure consistency, but in most cases, the variance was only two or three degrees indicating the calibration was correct.

Tip Type Offset (°C) RTMS 002 C MS -10 RTMS 022 S MS -18 RTPS 013 S MS -29 RTPS 002 S MS -23 RTPS 001 C MS -8 RTUS 016 C MS (#1) +5 RTUS 016 C MS (#2) +7 RTUS 004 C X MS +22

It seems that the tip offsets range from -23 to +22°C which is a bit of a range. Offsets of about 10°C would generally not be considered significant, when considering the accuracy of temperature regulation and the accuracy of the thermocross sensor combined. However, as measured offsets did exceed this value, it implies that the use of uncalibrated tips may result in noticeable temperature offsets.

Tip Heat-Up and Recovery

I had proposed the measurement of tip heating and temperature stability using a thermocouple and the B&K Precision DAS240BAT Multi-Channel recorder. Unfortunately, it is difficult to maintain reliable contact between a bead thermocouple and soldering iron tip. Furthermore, applying uncontrolled amounts of solder to poorly-defined patches of PCB will result in variances rendering data difficult to interpret.

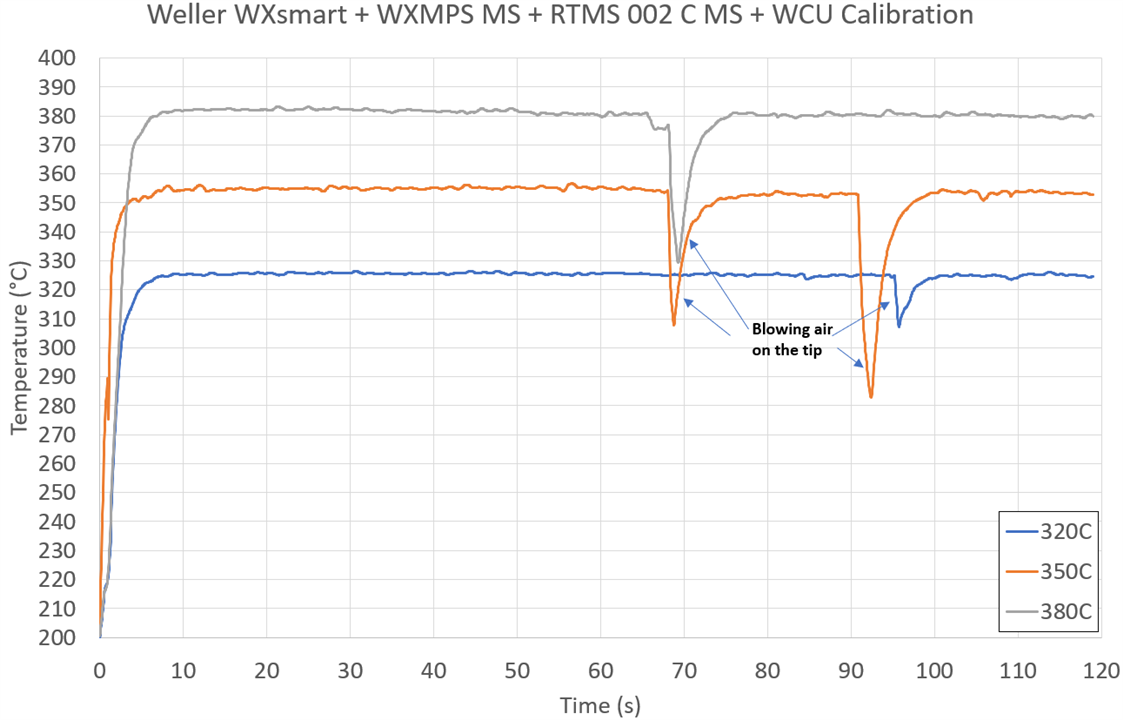

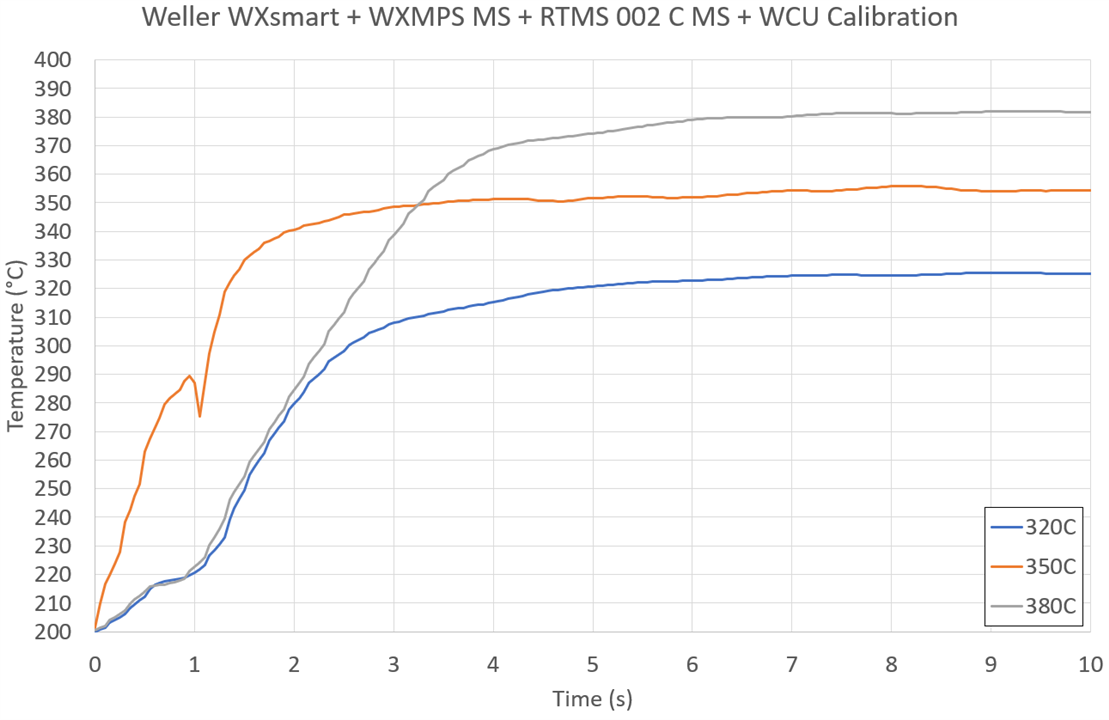

As a result, I decided to borrow the thermocross on the WCU and connect that to the DAS240BAT as the sensor. This allows me to get much better time resolution of temperature. I opted to test an RTMS 002 C MS and RTUS 016 C MS tip to demonstrate the capabilities of the WXMPS MS and WXUPS MS handpieces.

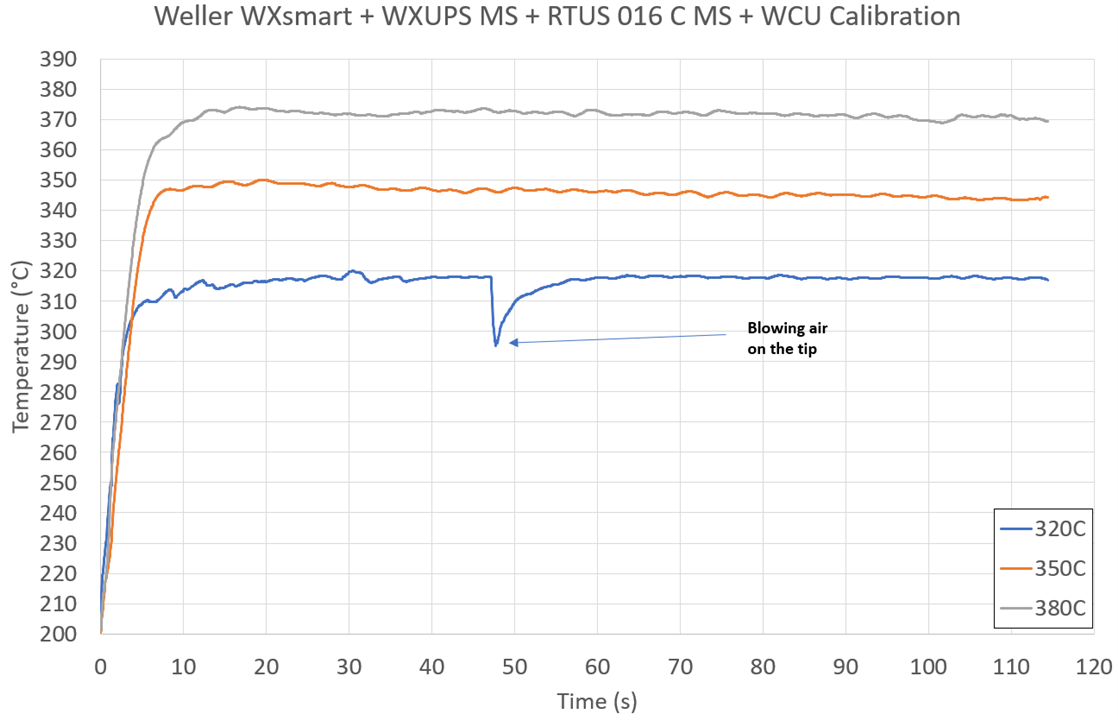

The sleep temperature was set to 180°C, however, measured at 200°C for the WXMPS MS + RTMS 002 C MS combination post-calibration. Nevertheless, I shook the sensor to bring it up to temperature at 320°C, 350°C and 380°C. The temperatures achieved are fairly close to the requested temperature (within 6°C) and showed no measurable overshoot. Blowing on the tip to perturb the system did not provoke any overshoot and the temperature returned closely to the set-point.

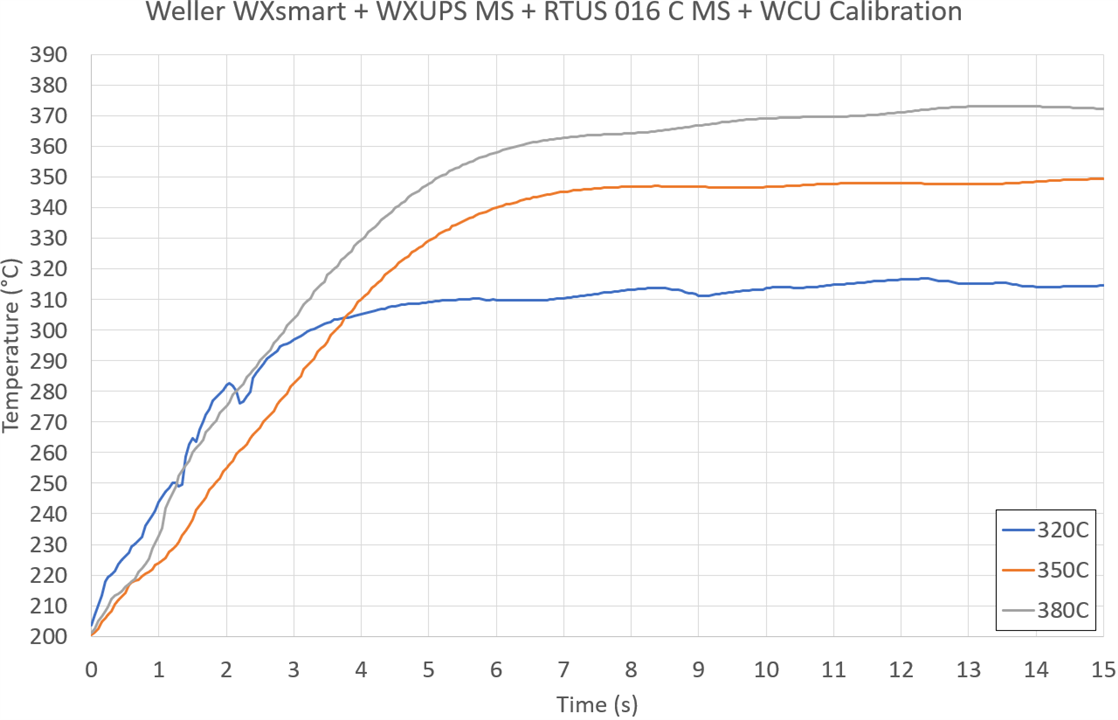

Zooming into the initial warm-up, it is clear that the warm-up time depends slightly on temperature selection (and perhaps also residual heat in the tip). Regardless, the curves suggest that the tip reaches temperature within five to six seconds normally.

Repeating the same with the WXUPS MS + RTUS 016 C MS combination post-calibration showed temperatures which were slightly below the set-point by up to 10°C and may have been due to the specific calibration. Nevertheless, this figure is close to the ±9°C specification.

As a larger iron with bigger thermal mass in the tip, it takes a little longer to reach temperature, but this is still a very speedy six to ten seconds.

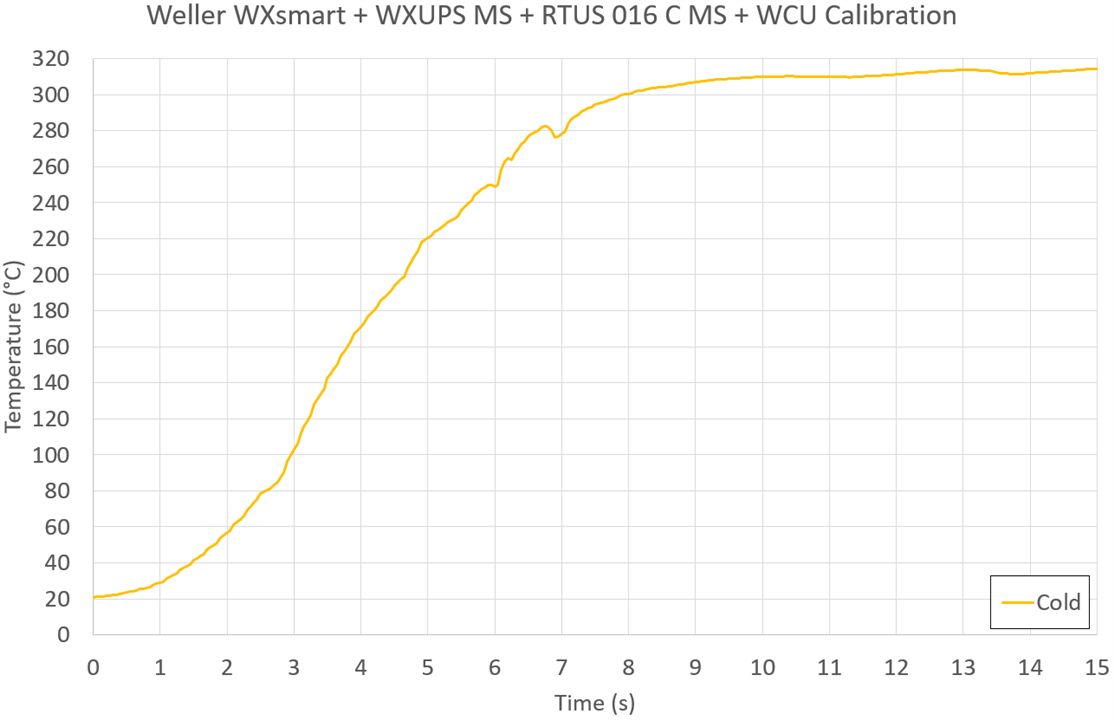

A start-up from cold to 320°C takes about ten seconds, or about four seconds faster than from the standby temperature of 180°C, making this a very speedy iron indeed!

nmap Scan

An nmap scan was performed to determine the services and open ports on the WXsmart.

PORT STATE SERVICE VERSION 80/tcp open http | fingerprint-strings: | FourOhFourRequest: | HTTP/1.1 404 Not found | Connection: keep-alive | Content-Length: 186 | Content-Type: text/html | Date: Sun, 23 Apr 2023 08:14:35 +0000 | Keep-Alive: timeout=15, max=65535 | <HTML><HEAD><TITLE>SEVENSTAX webserver</TITLE></HEAD><BODY><DIV ALIGN=CENTER><FONT SIZE=+4><BR><BR><BR>Sorry, the requested file does not exist on this server.</FONT></DIV></BODY></HTML> | GetRequest: | HTTP/1.1 404 Not found | Connection: keep-alive | Content-Length: 186 | Content-Type: text/html | Date: Sun, 23 Apr 2023 08:14:15 +0000 | Keep-Alive: timeout=15, max=65535 | <HTML><HEAD><TITLE>SEVENSTAX webserver</TITLE></HEAD><BODY><DIV ALIGN=CENTER><FONT SIZE=+4><BR><BR><BR>Sorry, the requested file does not exist on this server.</FONT></DIV></BODY></HTML> | HTTPOptions: | HTTP/1.1 200 OK | Allow: OPTIONS,GET,POST | Connection: keep-alive | Content-Length: 0 | Date: Sun, 23 Apr 2023 08:14:20 +0000 | Keep-Alive: timeout=15, max=65535 | RTSPRequest: | HTTP/1.1 200 OK | Allow: OPTIONS,GET,POST | Connection: keep-alive | Content-Length: 0 | Date: Sun, 23 Apr 2023 08:14:25 +0000 | Keep-Alive: timeout=15, max=65535 | SIPOptions: | HTTP/1.1 200 OK | Allow: OPTIONS,GET,POST | Connection: keep-alive | Content-Length: 0 | Date: Sun, 23 Apr 2023 08:15:48 +0000 |_ Keep-Alive: timeout=15, max=65535 443/tcp open ssl/https | fingerprint-strings: | FourOhFourRequest: | HTTP/1.1 404 Not found | Connection: keep-alive | Content-Length: 186 | Content-Type: text/html | Date: Sun, 23 Apr 2023 08:14:33 +0000 | Keep-Alive: timeout=15, max=65535 | <HTML><HEAD><TITLE>SEVENSTAX webserver</TITLE></HEAD><BODY><DIV ALIGN=CENTER><FONT SIZE=+4><BR><BR><BR>Sorry, the requested file does not exist on this server.</FONT></DIV></BODY></HTML> | GetRequest: | HTTP/1.1 404 Not found | Connection: keep-alive | Content-Length: 186 | Content-Type: text/html | Date: Sun, 23 Apr 2023 08:14:22 +0000 | Keep-Alive: timeout=15, max=65535 | <HTML><HEAD><TITLE>SEVENSTAX webserver</TITLE></HEAD><BODY><DIV ALIGN=CENTER><FONT SIZE=+4><BR><BR><BR>Sorry, the requested file does not exist on this server.</FONT></DIV></BODY></HTML> | HTTPOptions: | HTTP/1.1 200 OK | Allow: OPTIONS,GET,POST | Connection: keep-alive | Content-Length: 0 | Date: Sun, 23 Apr 2023 08:14:27 +0000 | Keep-Alive: timeout=15, max=65535 | RTSPRequest: | HTTP/1.1 200 OK | Allow: OPTIONS,GET,POST | Connection: keep-alive | Content-Length: 0 | Date: Sun, 23 Apr 2023 08:14:48 +0000 | Keep-Alive: timeout=15, max=65535 | SIPOptions: | HTTP/1.1 200 OK | Allow: OPTIONS,GET,POST | Connection: keep-alive | Content-Length: 0 | Date: Sun, 23 Apr 2023 08:16:03 +0000 |_ Keep-Alive: timeout=15, max=65535 | ssl-cert: Subject: commonName=1660307220017/organizationName=Weller/countryName=MX | Issuer: commonName=Production PC CA Mexico Weller PKI/organizationName=Weller/countryName=MX | Public Key type: unknown | Public Key bits: 256 | Signature Algorithm: sha256WithRSAEncryption | Not valid before: 2022-07-26T22:48:34 | Not valid after: 2100-12-31T23:59:59 | MD5: 8a79 35d6 badf 2069 f61d b795 7b45 7569 |_SHA-1: 0a6a 785a 31e7 8f5b ff42 9356 075d 2da9 1f99 3d74 5353/udp open zeroconf? | dns-service-discovery: |_ Address=xxx.xxx.xxx.xxx

The results indicate the presence of an Sevenstax HTTP/S web server on Port 80 and 443 and Zeroconf on Port 5453 in UDP. This makes for a very secure device as it is not exposing ports needlessly and the web server does not serve any useful pages on default paths.

Conclusion

It’s not all that easy to test a soldering station in a quantitative, meaningful way, but I tried it nonetheless. Testing power consumption using a Tektronix PA1000 Power Analyser revealed zero standby current for WXsmart and WXair units due to the use of hardware power switches. Idle power consumption measured 5.895W and 2.434W respectively, for a total of 8.329W which is reasonable. Quiescent standby current of the WCU was measured by a Keithley 2450 SourceMeter at 8.2µA with operational current of 2.8mA corresponding to about 196 hours from a 9V PP3 battery.

Calibrated tip temperature offsets using the Weller WCU ranged from -23 to 22°C which is quite a spread. While an offset of around 10°C could be acceptable, this suggests that some tips may not provide the optimal temperature if used without prior calibration.

Tip heat-up and recovery checks with a B&K Precision DAS240BAT Multi-Channel Recorder and ther thermocross from the WCU revealed no measurable overshoots and temperatures within 6°C for the WXMPS MS + RTMS 002 C MS combination post-calibration. Heat-up times from standby are around five to six seconds. The WXUPS MS + RTUS 016 C MS combination post-calibration had temperatures within 10°C which may have been due to a poor calibration but is close to the ±9°C specification. No overshoots were recorded and warm-up times from standby ranged from six to ten seconds. Both results show quite speedy warm-up and well-controlled temperature behaviour even when perturbed by blowing on the tip.

Network audits using nmap revealed the presence of an Sevenstax HTTP/S web server on Port 80 and 443 and Zeroconf on Port 5453 in UDP. No other ports were open, ensuring the device has a limited attack surface. Furthermore, the websever does not expose any useful pages on default paths.

---

This blog is part of the Weller WXsmart Connected Hand Soldering Platform RoadTest Review.