This is a follow up on ntewinkel blog of a week or so ago:

Since I use dollar store nail polish as a circuit sealer and insulator I decided to do some tests to confirm my assumptions that it is a good insulator. Fortunately my new inexpensive Megger arrived a couple days ago so I decided to learn how to use it and test the insulation properties of nail polish at the same time.

The plan was to put some solid wire on a piece of paper separated by 1 cm. Then a bead of nail polish would be painted between the wires and the megger would be used to test for resistance in the polish. Before I put the polish on the test bed I ran a dry test on the megger as pictured below.

To my surprise I got roughly 3.5 G Ohms on each of my test positions. No polish was involved at this point so this left me with a possibility of the paper or the scotch tape that was used to secure the wires. A two step experiment quickly showed me that the scotch tape was higher resistance than my meter could read but that the paper had approximately 3 G ohms per cm^2.

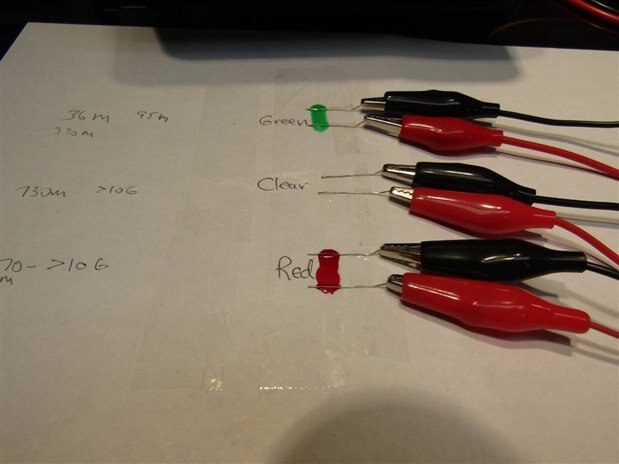

The test bed was reconfigured so that the wire was insulated from the paper by a layer of scotch tape. A dry test was run of each test position and all were above the 10 G ohm limit of my meter.

In the next tests, one by one a bead of nail polish was painted between the wires and the megger was monitored. The Red Polish began near 70 M Ohms and went to OL on the 10 G Ohm scale as it dried in about 10 minutes. The Clear Coat Nail Polish began wet at 700 M Ohms and went to OL on the 10 G Ohm scale in less than 3 minutes. The Green began at 36 M Ohms and slowly over 30 minutes increased until it too went OL on the 10 G Ohm Scale.

I also did some experiments with a thin layer of polish between 2 pieces of aluminum.

Even after drying for a day I suspect that the polish between the 2 pieces of metal never dried. When tested with a capacitor meter I got a reading of 3.6 uF. This was confirmed on 2 different cheap LCR meters and the polarity of the tester probes had little effect. When checked for Ohms I would get a reading of 1.35 M ohm with the meter probes in one polarity and 1.56 M Ohms when they were in the opposite polarity. When the voltage was measured between the two aluminum plates I got a reading of 250 mV with a 10 M Ohm/Volt meter so it would be loading the "Nail Polish Battery" slightly.This of course explained why the resistance varied with the polarity of the probes. While this didn't help my confidence in Nail Polish as an insulator I do believe that I am the first person ever to invent a Nail Polish Battery. Somebody quick, write me up in a journal or something.

The lesson here is that there is a lot of interesting things to learn every time we stop and look closely at something.

John

Top Comments