When we think about system failures, we often blame software bugs, processor malfunctions, or power supply issues. But there is a silent culprit that frequently gets overlooked - Connectors. These small components may seem insignificant, yet a single faulty connector can halt an entire operation, damage expensive hardware, or even put lives at risk. In industries like automotive, data centers, industrial automation, and aerospace, connector failures are not just inconvenient - they're costly.

Let’s explore why connectors fail, what those failures can really cost, and how to avoid them using high-reliability solutions from innovators like Amphenol.

What causes connector failures?

Connector failures often stem from one or more of the following issues:

1. Poor Contact Reliability

Over time, connectors can develop micro-movements or corrosion, especially in harsh environments. This leads to signal degradation or complete failure.

2. Improper Mating / Unmating

Frequent mating cycles or poor alignment can wear out connectors, especially those without proper retention features like Terminal Position Assurance (TPA) or Connector Position Assurance (CPA).

3. Thermal or Electrical Overload

Exceeding current ratings or operating in high-temperature environments can deform plastic housings, melt contacts, or cause arcing.

4. Vibration and Mechanical Stress

In industrial or automotive applications, vibration can loosen connections or cause stress fractures in solder joints.

5. Ingress of Dust, Moisture or Chemicals

Environmental exposure, especially in outdoor or factory-floor use, can corrode terminals or short out connections — particularly if connectors lack proper sealing (IP ratings).

The Real-World Cost of Connector Failures

- Data Centers: A loose or degraded high-speed backplane connector can lead to data loss, increased latency, or downtime - costing thousands of dollars per minute.

- EVs and Automotives: A failed power or signal connector in a critical ADAS (Advanced Driver-Assistance System) module could lead to catastrophic vehicle malfunctions.

- Industrial Automation: Downtime due to sensor or actuator disconnection can interrupt production lines, costing millions in delayed output.

- Medical Devices: A single faulty connector in a life-saving device can lead to loss of life or legal liability.

How to Avoid Costly Failures: Smart Design Choices with Amphenol

Preventing these issues starts with selecting connectors that are designed for your applications environmental, mechanical, and electrical demands. Here’s how Amphenol’s product line addresses common failure points:

PwrBlade ULTRA HD+ Cable Assembly

Designed to handle up to 84A per contact, this connector significantly reduces thermal stress and overheating, one of the top causes of power connector failure. Its modular design and low-profile housing help ensure proper airflow and easy integration, reducing risks of mating misalignment or cable strain in high-density server environments.

ComboNET Automotive Modular Connector

Automotive environments face extreme vibration, temperature cycling, and moisture — all major failure triggers. ComboNET addresses these with metal shielding, robust sealing, and a modular design that combines power, signal, and data lines in a space-efficient footprint. It meets USCAR-2 standards for durability and environmental resistance.

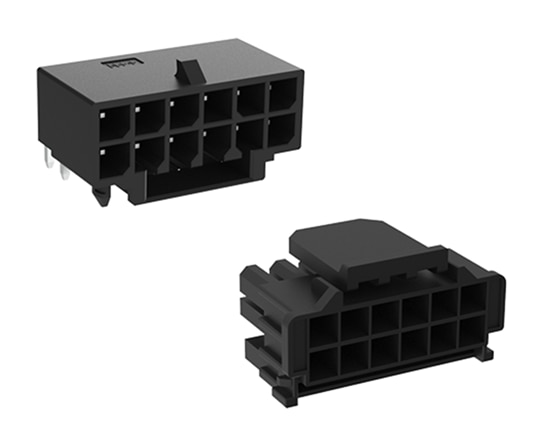

Micro Power Top PCIE® CEM 5 Power

With a low mating force and support for up to 9.5 A per pin, this connector reduces mechanical wear during repeated insertions. The robust contact design minimizes the risk of contact deformation and ensures a stable connection for high-power PCIe cards.

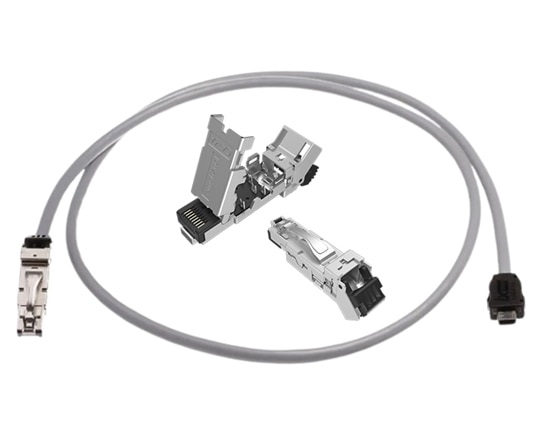

Industrial RJ Plugs & Cable Assemblies

In factory or field environments, dust and moisture can quickly degrade unprotected connectors. Amphenol’s IP-rated Industrial RJ series provides sealed, EMI-shielded connectivity with field-terminable plugs, preventing corrosion, short circuits, and signal interference.

112G PAM4 Mini Cool Edge 0.60mm Card Edge Connectors

For high-speed data systems, signal loss and crosstalk are major concerns. These fine-pitch connectors are engineered with advanced PCB interface design and shielding to preserve signal integrity even at 112G PAM4 speeds. This avoids data corruption or transmission errors that can lead to costly debugging or downtime.

Best Practices to Prevent Connector Failures

1. Never push a connector to its rated limits - Design with a margin

2. Match the connector to the environment (IP rating, vibration resistance, temperature range)

3. Use locking features (CPA, TPA) to ensure reliable mating.

4. Choose proven suppliers with high-quality manufacturing standards like Amphenol.

5. Design for accessibility - easy maintenance means less chance of user error during servicing.

The Big Picture

Connectors may be small, but the impact of their failure is anything but. Whether it's halting a server farm or compromising vehicle safety, the costs - both financial and operational can be enormous. The good news is that these failures are entirely preventable with the right design choices, materials, and partners.

Amphenol’s advanced connector technologies give engineers the tools they need to build robust, reliable systems that perform in the most demanding environments. Don't let a $5 parts be the weak link in your million-dollar system.

Have you ever experienced a costly failure caused by a simple connector? what did you learn?